Never Overlook These Automotive Electrical Connectors Types

Automotive electrical connectors types are crucial for the functionality of a car. They play a vital role in ensuring that various car components operate effectively. These connectors are essential for maintaining the proper functioning of brakes and controls in a vehicle. Neglecting them can lead to significant issues, including compromised safety while driving. Utilizing high-quality connectors results in increased longevity and improved repair outcomes. This ultimately contributes to the safety and optimal performance of the car's electrical system. Understanding the various automotive electrical connectors types is key to ensuring the safety and efficiency of vehicles.

Grouping Connectors by How Well They Work

Knowing How Well They Work

Car connectors need to meet certain rules. These rules make sure they are safe and work well. Connectors are grouped by how they handle things like heat and shaking.

T2 Type

T2 connectors go in parts for passengers. They work well in normal temperatures. This makes them good for inside the car, like for radios and air conditioning.

T3 Type

T3 connectors are for engine parts. They can take more heat than T2 ones. This makes them great for under-the-hood where it's hotter. Their strong build keeps them working even when it's tough.

T4 Type

T4 connectors are used near hot parts of the car. They can take more heat than T3 ones, so they don't break in very hot places. They're used near exhausts and other hot spots.

T5 Type

T5 connectors handle the most heat, up to 175 degrees Celsius. They're needed where it's super hot, keeping important systems running safely.

Why These Groups Matter

Knowing these groups helps pick the right connector for each job. Each group has special benefits that make car systems safer and better.

Heat Handling

Handling heat is key for connector performance. Connectors must survive the heat in different car areas without breaking down.

Right Fit

Right fit means choosing a connector that suits its job best. Picking correctly boosts how well car systems work overall.

Specific Types of Connectors

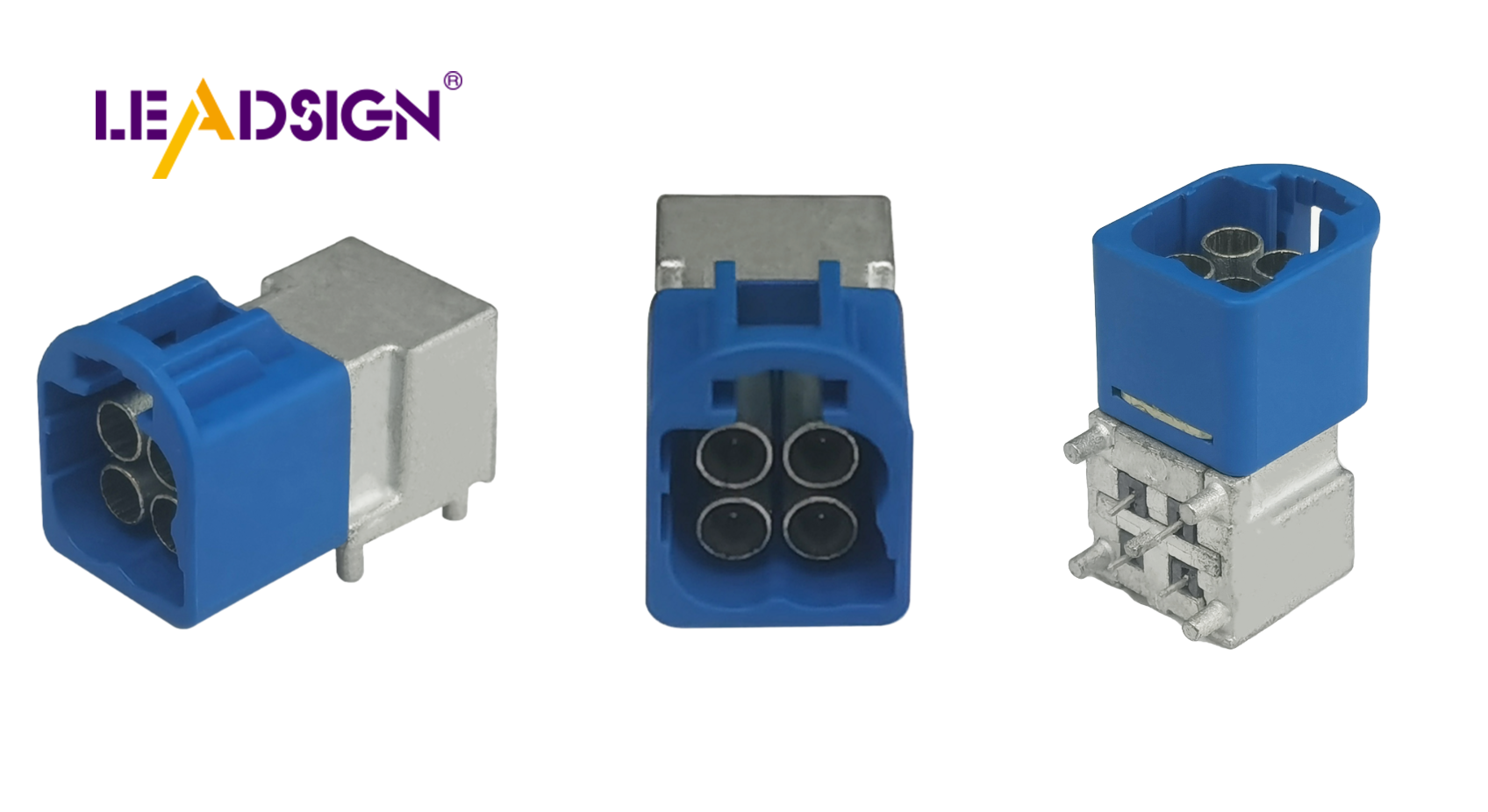

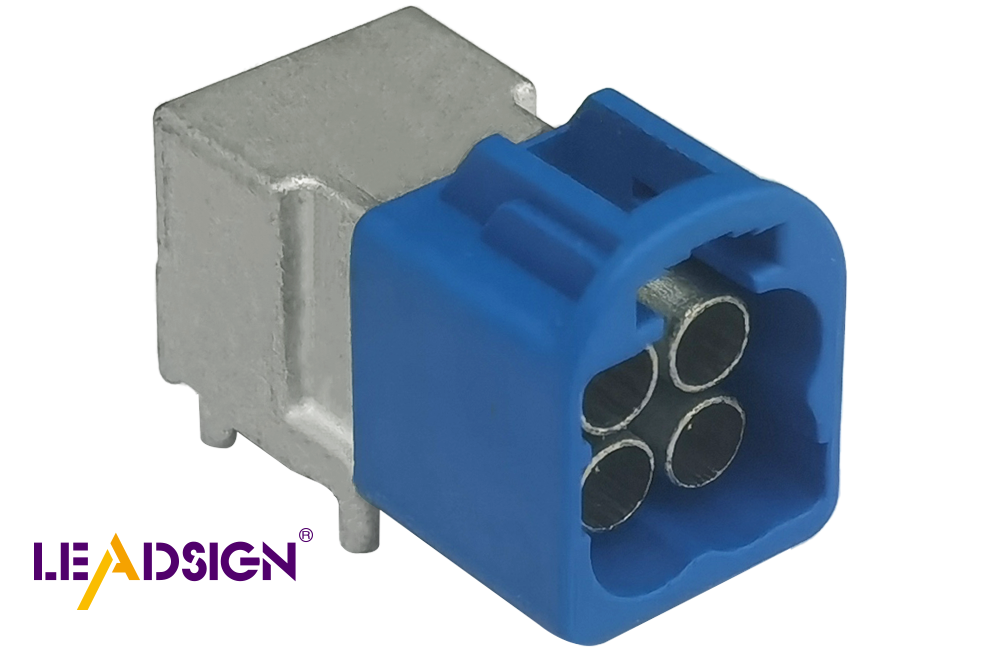

HSD Connector

The HSD Connector is very important in car connectors. It sends fast data, which is crucial for new cars.

Mechanical Properties

The HSD Connector is strong and works well. It has two locks to keep it safe and steady. The crimp connection keeps it together in different situations. High cable force stops it from unplugging by accident. Its design helps avoid wrong connections with different codes on the plastic part.

Applications in Automotive Electronics

In cars, the HSD Connector is used a lot because it handles fast data well. It works with USB signals, LVDS camera signals, and IEEE 1394, so it's good for digital systems and displays. It also works with Ethernet and USB types like USCAR 30 and Mini USB, making it useful in many ways. With high signal quality and speed up to 1.6 Gbps, it's great for telematics, video through GVIF, and phone stations. It can connect over long distances up to 10 meters too.

Other Automotive Electrical Connectors Types

Besides the HSD Connector, other car connectors are also important.

LVDS Connectors

LVDS Connectors are key for sending low voltage signals fast without much interference. They are used in cameras, displays, and other digital systems in cars.

USB Connectors

USB Connectors are common in today's cars. They help link electronic devices like phones and tablets by transferring data and power. In car connectors types, they make sure devices work well together for a better experience.

Standards and Testing Rules

USCAR 2 Rule

The USCAR 2 Rule is very important for cars. It makes sure connectors work well all the time. This rule checks from making to using them in real life. It looks at low voltage systems so they work right in different places.

Why Safety Matters

Safety is super important for cars. The USCAR 2 Rule has tough tests to make sure connectors don't break when stressed. By following these rules, makers can promise their stuff stays strong, even when it's hard. This helps stop accidents from connector problems.

Being Strong and Lasting Long

Connectors need to be strong and last long. The USCAR 2 Rule has tests like hot-cold changes and stress checks. These tests show if connectors can handle daily use. When they pass, it means the car's electrical parts are reliable.

Other Testing Rules

Besides the USCAR 2 Rule, there are other tests for car connectors. These look at things like weather that might affect them.

Weather Tests

Weather tests see how connectors do in different conditions. They check if they work in heat, wetness, and bad stuff like rust-makers. These make sure connectors stay safe anywhere.

Shaking and Wetness Checks

Shaking and wetness checks are key for car connectors. Cars move a lot, which can make connectors loose or broken. Shaking tests keep them tight. Wetness checks see if water messes with them without breaking them down. These are needed to keep the car's electric parts working well.

Automotive electrical connectors are important for car safety and performance. Picking the right ones is key. Important things to think about:

Performance Standards: Know T2, T3, T4, and T5 to pick connectors that handle different conditions.

Connector Types: Use HSD, LVDS, and USB for good fit and work in cars.

Testing Standards: Follow rules like USCAR 2 for safe and strong connectors.

Right connectors make cars last longer and stay safe. Always think about these when choosing car electrical connectors.

See Also

Significance of Fakra Auto Connectors in Contemporary Cars

The Significance of FAKRA Connectors in Auto Uses

The Significance of Fakra Connectors in Auto Sector