Automotive Electrical Connectors Types Explained

Car electrical connectors are very important in today's vehicles. They help different parts communicate with each other, enhancing safety and performance. The market for these automotive electrical connectors types is substantial, valued at approximately USD 6.71 billion in 2023. This indicates a growing demand for various kinds of connectors, each designed for specific functions. They facilitate power and signal transmission in cars, ensuring that vehicles operate efficiently and safely on the road.

Basics of Car Electrical Connectors

Simple Categories

Car electrical connectors are key in car systems. They have different types for specific jobs. Knowing their categories helps pick the right one.

By How They Connect (e.g., crimp, solder)

Crimp Connectors: These use a tool to join the wire and connector. Crimping makes a strong link, good for cars with lots of shaking.

Solder Connectors: Soldering melts metal to bond wire and connector tightly. This gives great electricity flow, perfect for permanent links.

By Job (e.g., power, signal)

Power Connectors: These handle lots of electricity and are used for batteries and power systems. They're built to take high power safely.

Signal Connectors: Signal connectors send data between car parts. They're crucial in engine control and entertainment systems where data must be accurate.

Rules and Guidelines

Car electrical connectors must follow rules to be safe and reliable. These rules help make, test, and install them properly.

Industry Rules (e.g., ISO, SAE)

ISO Rules: The International Organization for Standardization sets design rules for car connectors worldwide ensuring safety and quality.

SAE Rules: The Society of Automotive Engineers makes rules for North American car connectors focusing on strength in tough conditions.

Why Following Rules Matters

Following industry rules is crucial for car connectors. It ensures they can handle tough conditions like heat or shaking in cars while fitting well with other parts to avoid electric problems.

Types of Automotive Electrical Connectors

Automotive electrical connectors types are important for car systems to work well. They link different circuits, helping parts talk and share power in the car. Knowing about these connectors helps choose the right one for each job.

Crimp-Style Connectors

Crimp-style connectors are very common in cars. They make a strong connection by squeezing the wire to the connector.

Features and Benefits

Durability: Crimp-style connectors handle stress and shaking, perfect for cars.

Ease of Use: A crimping tool is needed to attach them, making it easy without soldering.

Versatility: They work well in many places like engine control.

Common Uses

Powertrain Systems: Used in powertrains for strong connections even when conditions are tough.

Infotainment Systems: Help connect infotainment parts, keeping data steady.

Distribution-Type Connectors

Distribution-type connectors are also key in cars. They spread power and signals to many circuits.

Features and Benefits

Efficiency: Manage power and signals well, making wiring simpler.

Space-Saving: Fit into small spaces, saving room inside the car.

Reliability: Work well even when conditions are hard.

Common Uses

Lighting Systems: Used in lights like headlights and taillights for good connections.

Safety Systems: Important for safety parts like airbags and ABS brakes.

Other Common Types

Besides crimp-style and distribution-type, there are more automotive electrical connectors types used often.

Blade Connectors

Blade connectors have flat metal that slides into place. They're easy to use when maintenance is frequent.

Applications: Often found in fuse boxes for quick connections.

Ring and Spade Terminals

Ring and spade terminals join wires to screws or studs. They're secure, great for grounding tasks.

Applications: Ideal for battery links ensuring stable connections.

Knowing these automotive electrical connectors types helps keep vehicle systems working safely. Each type has special features making them fit certain jobs in cars.

Uses of Automotive Electrical Connectors

Car electrical connectors are like the backbone of car systems. They help parts talk to each other and work well. These connectors join wires, making sure electricity flows smoothly. This is important for cars to run safely and efficiently.

Engine and Power Systems

Connectors in engines and power systems keep cars running well and safe.

Connectors for Sensors and Actuators

These connectors are key for engine sensors. They send correct data between the engine's brain and sensors. This helps save fuel and cut pollution. LEADSIGN-AUTO, a connector expert, says these can handle heat and shaking in engines.

High-Current Connectors

High-current connectors carry lots of electricity. They're used in starters and alternators, starting the engine, and charging batteries. Their strong build stops overheating, lasting a long time.

Entertainment Systems

Entertainment systems need connectors for a smooth experience.

Audio and Video Connectors

Audio/video connectors move sound/picture data in cars. They link speakers, screens, head units ensuring clear sound/picture with less interference.

Data Connectors

Data connectors are vital for modern cars with smart tech. They let cars share info with phones or GPS devices quickly, keeping everything updated.

Safety Systems

Safety systems rely on good connectors to work right.

Airbag/ABS Connectors

Airbag/ABS connectors are crucial for safety gear like airbags/brakes. They must be super safe to work during emergencies, resisting water/corrosion over time.

Light/Signal Connectors

Light/signal connectors are found in headlights/signals. They ensure lights work well even when wet/dusty so drivers see clearly communicate on roads.

Expert Opinion: LEADSIGN-AUTO says picking the right connector type cuts risks boosts car safety by testing them thoroughly to improve performance.

Knowing how automotive electrical connectors work helps pick the best ones for each part of a car system ensuring it runs safely reliably.

Knowing about different automotive electrical connectors types is important for car safety and how well it works. These connectors help car parts talk to each other easily. Picking the right connector when designing a car can change how well the system works, how easy it is to use, and its cost.

Important Tip: Picking the right connector keeps cars safe and saves money.

By thinking about things like electricity levels, voltage, and weather conditions, you can stop overheating or breaking, making the car more reliable and efficient.

See Also

Understanding HSD Connectors Essential for Automotive Applications

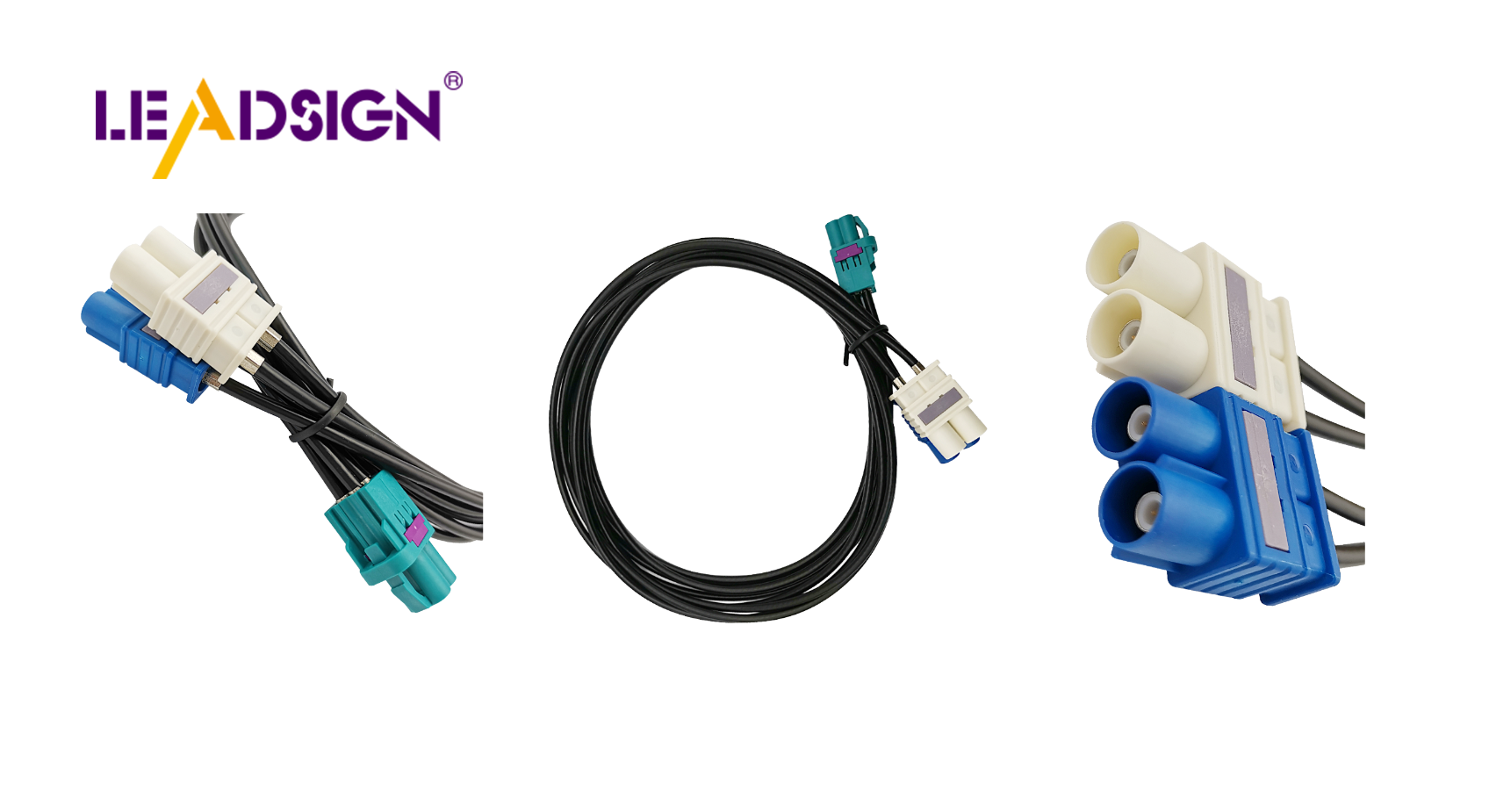

Why Fakra Connectors Are Crucial for Today's Vehicles

A Comprehensive Overview of Ford's Fakra Connectors