Automotive Electrical Connectors Types Explained Simply

Car electrical connectors are important parts in cars. They connect different electrical systems for smooth running and are essential for preventing electrical problems. Understanding the various automotive electrical connectors types is key for good car care. This knowledge helps in finding the right type for each need and prevents potential issues. By being informed about these connectors, people can take better care of their cars, ensuring they last long and operate efficiently.

Types of Car Electrical Connectors

Knowing about car electrical connectors is important for fixing cars. These connectors help different car parts work well together. Let's look at some common types.

Blade Connectors

What They Are Like

Blade connectors, also called spade connectors, have a flat metal piece. This piece fits into a matching slot. They are easy to connect and disconnect. Blade connectors come in many sizes and are usually made from brass or copper. These materials make them strong and good at carrying electricity.

Where They're Used in Cars

In cars, blade connectors are used in wiring harnesses and fuse boxes. They link wires to things like headlights and tail lights. Their simple use makes them popular with car makers and repairers.

Pin Connectors

What They Are Like

Pin connectors have one or more pins that go into sockets. They give a safe connection, which is good when stability is needed. Pin connectors come in different sizes and shapes, allowing for design flexibility.

Where They're Used in Cars

Pin connectors are found in engine control units (ECUs) and sensors. They stay connected even with vibrations, keeping the car running smoothly.

Ring Connectors

What They Are Like

Ring connectors have a round metal ring that goes over a bolt or stud. This makes a strong connection, perfect for high power needs. Ring connectors are often made from copper or aluminum for good electricity flow.

Where They're Used in Cars

In cars, ring connectors join battery cables and grounding wires. Their tough design handles high power well, helping spread power through the car.

By learning about these connector types, people can choose the right ones for their needs. This helps keep cars working well for longer.

Specialty Connectors

Specialty connectors are very important in cars. They solve special problems and meet high-performance needs.

Description and Characteristics

These connectors come in different shapes for specific jobs. Razor Beam™ Self-Mating Connectors are fast and save space. They fit many car uses because they are flexible.

Micro Blade & Beam 0.40 mm & 0.50 mm Fine Pitch Connectors are tiny and slim, saving space on boards. Their small size helps in tight spots in car electronics.

The mPOWER® Ultra Micro Power Connectors can handle up to 18 Amps. They work well with different setups, making sure power flows well in cars.

Lastly, Tiger Eye™ High-Cycle, High-Reliability Connectors are strong and last long. They handle power from 3 to 60 Amps and stay safe even in tough places.

Common Uses in Vehicles

Specialty connectors are used in key parts of cars:

Autonomous Driving Systems: These need strong connections for self-driving features.

Driver Assistance Systems: They keep sensors and cameras working safely.

Infotainment and Navigation: Fast data is needed here, so these connectors help.

Power Distribution: In electric cars, they manage big power loads safely.

Knowing about these connectors helps people pick the right ones for their car needs. This keeps cars running well and lasting longer.

Uses of Each Connector Type

Knowing how different car connectors are used helps pick the right one. Each type has special jobs in cars, making them work well and last long.

Blade Connectors in Cars

How they're used and why they're good

Blade connectors are simple and strong. They connect wires to things like headlights and fuse boxes. Their flat shape makes them easy to plug in and out, which helps with repairs. Made from brass or copper, they carry electricity well and last long. These connectors are great when you need to unplug often but still want a safe connection.

Pin Connectors in Cars

How they're used and why they're good

Pin connectors keep connections steady in cars. They're found in engine control units (ECUs) and sensors. With pins that fit into sockets, they stay connected even when the car shakes. This is important for sending signals right, so the car runs smoothly. Pin connectors can be different sizes or shapes to fit car needs.

Ring Connectors in Cars

How they're used and why they're good

Ring connectors make strong links for high power in cars. They join battery cables and grounding wires by fitting over bolts tightly. Made from copper or aluminum, they let electricity flow well. They handle big power loads, spreading it through the car safely.

By learning about these connector types, people can choose wisely for their cars. This helps cars run better and last longer.

Special Connectors in Car Systems

Special connectors are very important in today's cars. They solve special problems and meet high needs in different uses. Knowing these car electrical connector types helps choose the right one.

Where They're Used and Why They're Good

Self-Driving Cars: Special connectors keep connections strong in self-driving cars. They help sensors and cameras work together for driving on their own. These connectors send data fast, which is needed for quick thinking.

Driver Help Systems: In driver help systems, special connectors keep things steady. They connect parts like radar and cameras, making sure data flows right. This helps with safety features like cruise control and lane help.

Entertainment and Maps: Fast special connectors are key in entertainment and maps systems. They move data quickly between devices, so music and videos play smoothly. They also help GPS work well for good directions.

Power Sharing: Special connectors handle power sharing in electric cars. They manage big power loads from the battery to other parts, helping the car run well and saving battery life.

Product Details:

Tiger Eye™ High-Cycle, High-Reliability Connectors: These have a tough system that lasts over 1,000 uses. They are very reliable and come in sizes of 0.80 mm, 1.27 mm, and 2.00 mm.

mPOWER® Ultra Micro Power Connectors: These give flexible power options from 3 to 60 Amps, great for small spaces needing good power flow.

Special connectors with their unique designs make car systems work better and last longer. By knowing these car electrical connector types, people can choose smartly for best performance of their cars.

Things to Think About When Picking Connectors

Material Choices

Why material matters for lasting and working well

The stuff a connector is made of is very important. It helps it last long and work well. Makers use brass, copper, or aluminum because they carry electricity well and are strong. Brass and copper let power move easily, so things work better. Aluminum is lighter but still good at carrying power. It's used when weight needs to be less. When picking a connector, think about how tough the material is. A strong material keeps the connector working right and stops electrical problems.

Size and Fit

Making sure it fits with car parts

Size and fit are super important for car connectors. The connector must be the right size for wires and parts to fit snugly. If it's too loose, it might not connect well, causing problems. To stop this, measure the wire size and part size before choosing a connector. Making sure it fits helps keep everything connected right, which is key for the car to work well. Right-sized connectors also make putting them in easier.

Environmental Toughness

Why standing up to heat, wetness, and rust matters

Car connectors deal with tough conditions like heat, wetness, and rust. They need to handle heat without breaking down. Keeping water out stops short circuits or rusting from happening. Materials that fight rust last longer because they don't get rusty or break apart easily. When picking a connector, think about where it will be used in the car's environment. A tough connector works well even when things get hard.

Connector Features

Other Things to Think About

When picking car electrical connectors, some features are very important. They help the connector work well and last long in cars.

Locking Mechanisms Locking systems keep wires connected safely. They stop wires from coming loose when things shake. A good lock keeps the connection steady and safe.

Color Coding Colors make it easy to know which wire is which. This helps during fixing or putting parts together. Different colors mean different jobs, stopping mix-ups.

Waterproof Seals Waterproof seals keep water out of connectors. They stop rust and short circuits, especially where it's wet or rainy. Good seals help connectors last longer.

Heat Resistance Heat-resistant connectors don't break in hot places. This is important near engines or hot parts. They stay strong even when it's really hot.

Flexibility and Bend Radius Flexible connectors can move without breaking wires inside them. The right bend stops wires from getting hurt when they twist or turn a lot.

Strain Relief Strain relief stops wires from bending too much at the ends. It keeps them from wearing out fast, making connections last longer.

By thinking about these features, people can choose the best connectors for their cars' needs. These features help keep the car's electric system working well and safely.

Picking the right automotive electrical connector is important for cars to work well and last long. Different connectors do different jobs, like blade connectors in fuse boxes or special ones in high-tech systems. When choosing, think about how strong the material is, if it fits well, and if it can handle tough conditions. Here are some easy tips:

Look at where it's used: Pick connectors that can take heat and wetness.

Check if it fits: Make sure connectors fit tightly with car parts.

Go for good quality: Choose connectors made from strong stuff like brass or copper.

By knowing these things, people can choose wisely and keep their cars running smoothly.

See Also

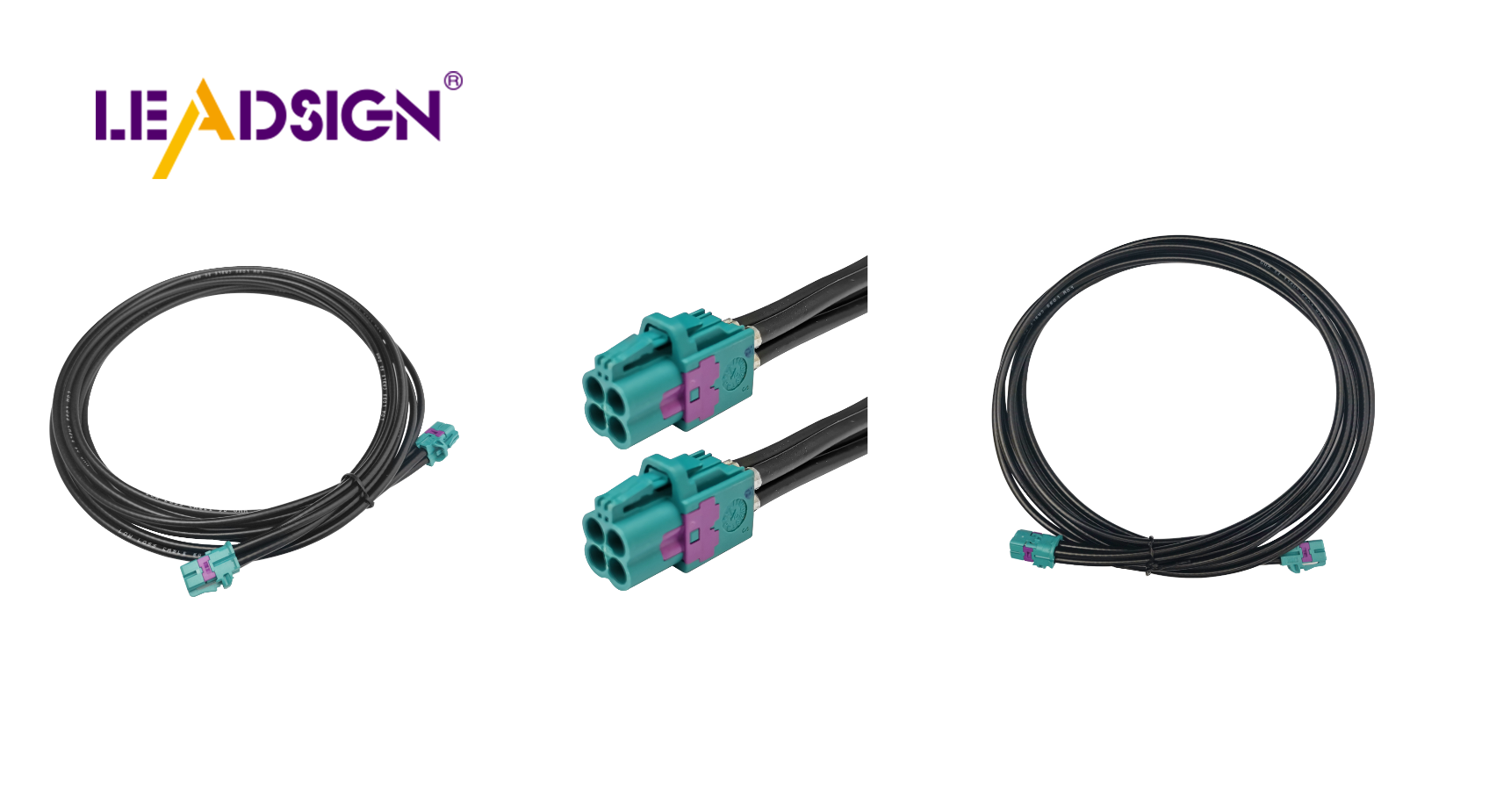

Understanding HSD Connectors Used in Cars Today

Why Fakra Connectors Matter in Today's Vehicles

Significance of Fakra Connectors for Automotive Applications