Exploring Automotive Electrical Connectors Types for Durability

Choosing the right automotive electrical connectors types is crucial for ensuring your car remains safe and operates efficiently. If these connectors fail, it can lead to significant issues. Approximately 45% of connector problems arise from poor contacts, highlighting the necessity for robust connectors. Connector failures occur more frequently than wiring issues in airplanes, making the selection of durable connectors essential. Reliable automotive electrical connectors types are vital for maintaining the proper functioning of your car's electrical systems.

Understanding Automotive Electrical Connectors

Definition and Function

What are automotive electrical connectors?

Automotive electrical connectors are important parts of your car's electronic systems. They connect different circuits, helping power and data move smoothly. These connectors make sure that systems like the stereo, navigation, and safety features work together well. By linking these systems, connectors help keep your car working properly.

How do they function in vehicle systems?

Connectors help parts of the car talk to each other. They create a strong link so signals can pass without stopping. This keeps your car running safely and smoothly. For example, connectors join the battery to the ignition system so you can start the car. They also connect sensors to the engine control unit for real-time checks. Without good connectors, these important jobs might fail and cause safety problems.

Importance of Durability

Why durability matters in automotive connectors

Durability is very important when picking car connectors. You need them to handle tough conditions like heat, shaking, and wetness. Strong connectors keep your car's systems working even in hard situations. Good quality ones lower failure risks, saving money on repairs and avoiding dangers.

Common issues with non-durable connectors

Weak connectors can cause many problems in cars. One issue is losing connection which might stop steering or braking from working right. Bad-quality ones may have assembly mistakes or not fit well, causing leaks or failures. These problems can be dangerous and costly to fix. Knowing why durability matters helps you choose better connectors for safe driving.

Exploring Automotive Electrical Connectors Types

Knowing about different automotive electrical connectors types helps you choose wisely for your car. Each type has special jobs and strong features.

Blade Connectors

Overview and use cases

Blade connectors are common in cars. They handle lots of electricity, so they work well for engines, lights, and music systems. You often see them in headlights and starters because they manage big electric loads.

Durability factors

Blade connectors last long because they are tough. They resist rust and heat, which is good for cars. Their tight fit keeps them connected even if the car shakes or moves.

Pin Connectors

Overview and use cases

Pin connectors, also called pigtail connectors, are important too. They do similar jobs as blade ones like engine control. They work in both small and big electric tasks, fitting many car parts.

Durability factors

Pin connectors are strong due to their solid build. They fit in small spaces easily because they're compact. Their lock keeps them steady even with shaking or heat changes.

Butt Connectors

Overview and use cases

Butt connectors are special because they can shrink with heat. They're used to fix wires or add more wire length safely.

Durability factors

Butt connectors stay strong thanks to their crimp sleeve inside. This makes a tight bond that conducts electricity well. The shrinking part protects from water and weather, keeping connections safe.

By learning about these automotive electrical connectors types, you can pick the best ones for your car's needs to keep it safe and working right.

Specialty Connectors

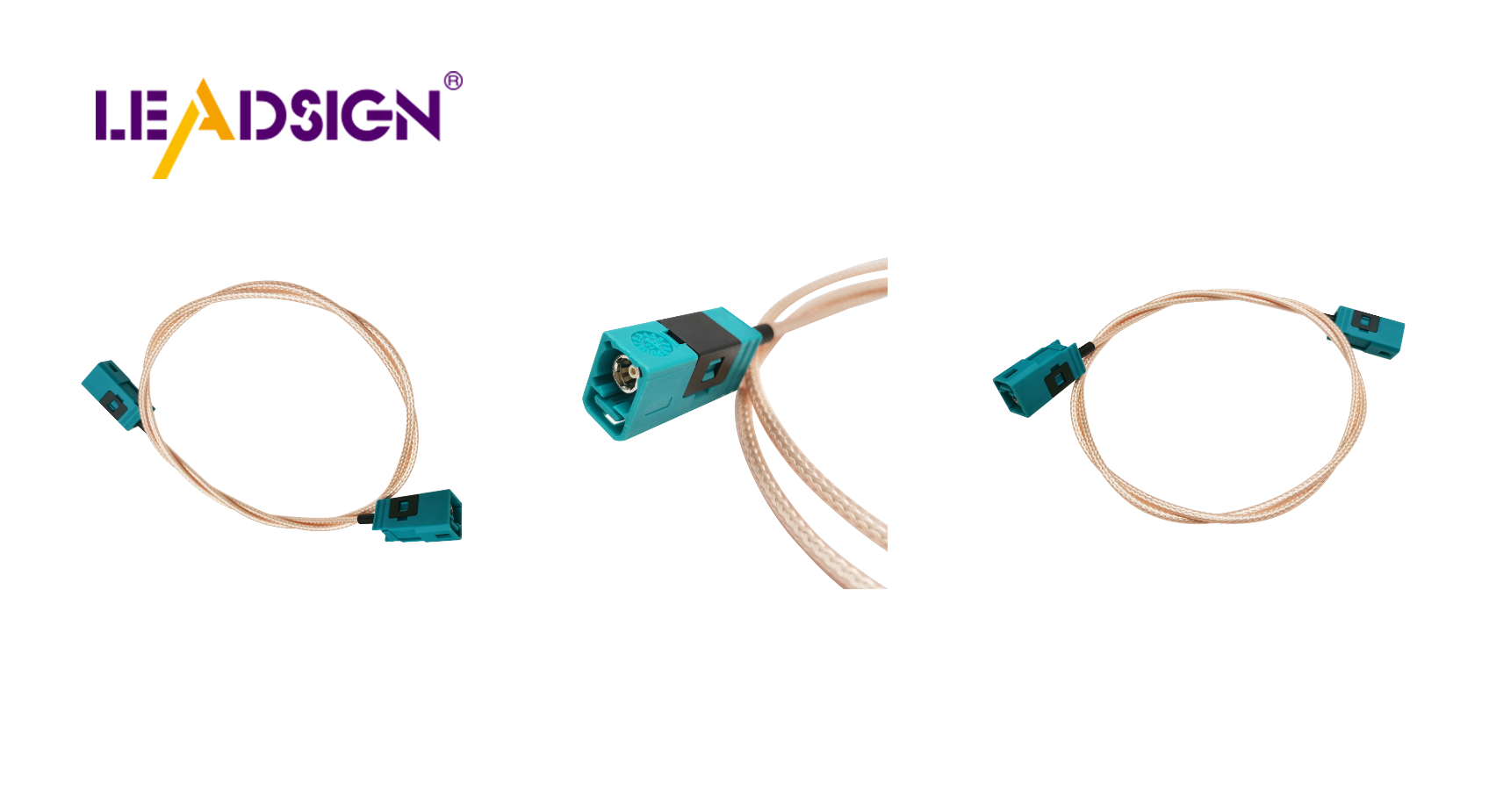

What they do and where they're used

Specialty connectors are important in cars. They work where regular ones can't. You find them in cool car tech like GPS and infotainment. These connectors help parts talk to each other well.

Specialty connectors have special jobs. Some stop interference from messing up signals. Others lock tight for safety. They're great for high-tech cars needing exact fits.

Why they last long

Durability is key for specialty connectors. They face tough stuff like heat, wetness, and shaking. They're built to handle these things well.

Look for strong materials that don't rust or break easily. Some have extra locks to stay put during bumps. Good specialty connectors keep your car's systems working right.

Buying Guide for Automotive Electrical Connectors

When picking automotive electrical connectors types, think about reliability and how well they work. This guide helps you choose wisely.

Material Considerations

Common materials used

Automotive electrical connectors types often use copper, brass, and plastic. Copper is great because it carries electricity well. Brass is strong and doesn't rust easily. Plastic covers parts to keep them safe.

Pros and cons of each material

Copper:

Pros: Carries electricity well.

Cons: Can rust if not coated.

Brass:

Pros: Strong and rust-resistant.

Cons: Not as good at carrying electricity as copper.

Plastic:

Pros: Light and protects well.

Cons: Might break in very hot places.

Pick the right material based on what you need and where you'll use it.

Compatibility and Fit

Ensuring compatibility with vehicle systems

Make sure the automotive electrical connectors types fit your car's systems. Check your car's parts details to match them with the connector. This makes sure everything works smoothly together.

Importance of proper fit

A good fit keeps connections tight. It stops things from coming loose and keeps signals moving well. Look for connectors that lock in place, especially if your car shakes a lot.

Environmental Resistance

Resistance to heat, moisture, and corrosion

Connectors should handle tough conditions like heat or wetness. Pick ones that resist these things so they last long. Some have special coatings to stop water or rust from getting in.

Selecting connectors for specific environments

Different places need different connector features. If it's humid, get waterproof ones. In hot areas, pick those that can take the heat without breaking down. Think about where you'll use them to keep them working well.

Frequently Asked Questions

How do I know if a connector is durable?

To find out if a connector is strong, check a few things. First, see what it's made of. Strong connectors use materials like brass or copper because they conduct electricity well and don't rust easily. Look for connectors with tough coverings like nylon, which handles heat better than vinyl. Also, look at the design. A good connector locks in place so it won't come apart when the car moves. Finally, think about the maker's reputation and any special certifications.

Can I use the same connector type for all vehicle systems?

Using one type of connector for everything in your car isn't a good idea. Different parts need different things. For example, new energy cars need connectors that can handle high heat and are waterproof. Regular car connectors might not need these features. Each part of your car, like the engine or radio, needs its own kind of connector to work right. So always pick connectors based on what each part needs.

What are the signs of a failing connector?

Knowing when a connector is going bad can stop problems before they start. One sign is when electrical stuff works sometimes but not always. You might also see damage like rust or broken pieces, especially if they're in tough spots. Loose connections mean wear or bad fit too. If you smell something burning or feel heat, it could be a bad connection causing extra resistance and heat buildup. Checking them often helps catch these problems early so your car stays safe.

Picking the right automotive electrical connectors is very important. They need to be strong and last long in your car. Here are things to think about when buying them:

Durability: Choose connectors that can handle tough stuff like heat, water, and shaking. Experts say testing them helps stop problems.

Material and Fit: Use copper or brass because they are good for carrying electricity and are strong. Make sure they fit well so they stay connected.

Environmental Resistance: Think about where you will use the connector. Water and rust often cause failures, so get ones with protection.

Focus on quality and making sure they match your car's needs. This keeps your car's electric parts working safely for a long time.

See Also

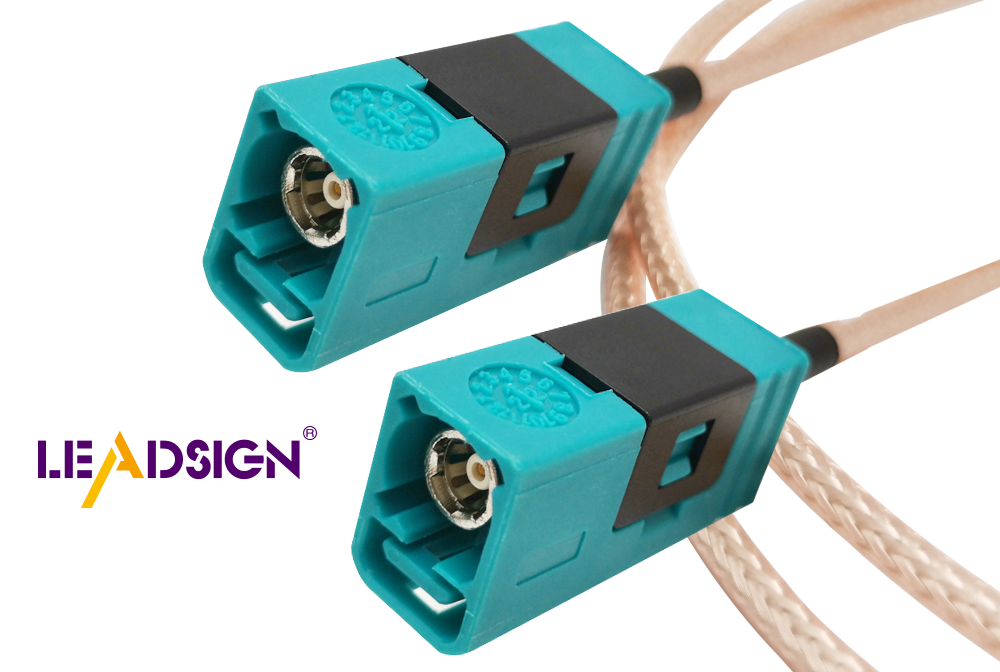

Understanding How Fakra Connectors Enhance Vehicle Performance

Why FAKRA Connectors Are Essential for Modern Vehicles

Enhancing Vehicle Data Flow with Advanced Connectors