Automotive Electrical Connectors Types Compared

Automotive electrical connectors are crucial for ensuring the efficient operation of a vehicle's electronic components. As vehicles become more sophisticated, the demand for improved automotive electrical connectors types increases. These connectors play a vital role in supporting systems such as infotainment and safety features. The market for these automotive connectors is rapidly expanding and is projected to be worth USD 24.08 billion by 2034. This growth is driven by the rising sales of trucks and buses, as well as advancements in automotive technology. There are various types of automotive electrical connectors, each designed for specific functions and requirements.

Classification Based on Performance Standards

Temperature Ranges

Car connectors need to handle different temperatures. This ensures they work well. Sorting by temperature helps pick the right connector.

T2 Category

T2 handles -40 to 100℃. These are for car parts where it's not too hot or cold. They balance cost and performance, perfect for regular car use.

T3 Category

T3 works from -40 to 125℃. Used in engines where it's hotter. They are tough and reliable for hard conditions.

T4 Category

T4 is near hot engine parts, handling -40 to 150℃. They work well in heat without losing safety or efficiency.

T5 Category

T5 goes up to -40 to 175℃, good for very hot places. They keep systems running even in extreme heat.

Typical Applications for Each Category

Knowing what each category does helps choose the right connector.

T2 Applications

T2 is in cars for things like radios and simple controls. They work well at normal temperatures.

T3 Applications

Engines use T3 because they can take more heat. Found in fuel systems where reliability is key.

T4 Applications

T4 is needed near turbochargers and exhausts. They're built to handle extra heat without breaking.

T5 Applications

Hot places like race cars use T5 connectors. They're strong enough for extreme heat, helping advanced tech work.

Automotive Electrical Connectors Types

HSD Connector

The HSD Connector is special because it is strong and flexible. It is made to meet the needs of car makers worldwide, making sure data moves fast.

Mechanical Properties

The HSD Connector has important features that make it work well:

Mechanical Keying: Stops wrong connections, keeping each link safe.

Locking Mechanism: Keeps connections steady against shakes and bumps in cars.

Color Coding: Makes it easy to spot and set up, lowering mistakes.

Compact Form Factor: Even with many features, it's small for tight spaces.

Applications

The HSD Connector works in many car systems, showing its usefulness:

Infotainment Systems: Helps send fast data for new entertainment systems.

Advanced Driver-Assistance Systems (ADAS): Keeps data flowing safely for important tasks.

Ethernet Applications: Works with Ethernet, meeting strict car rules.

Digital Infotainment Electronics: Fits well with digital gadgets and networks.

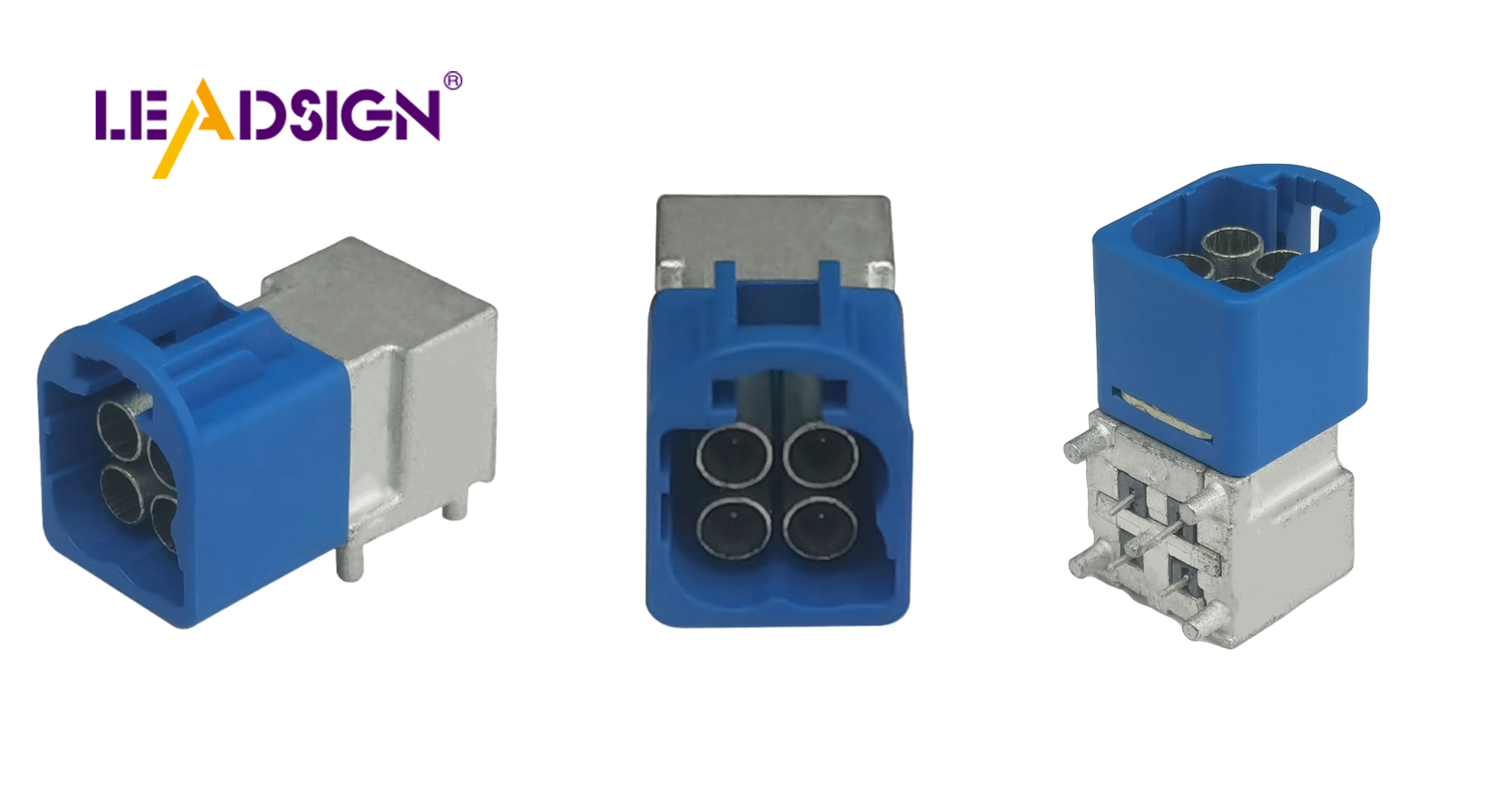

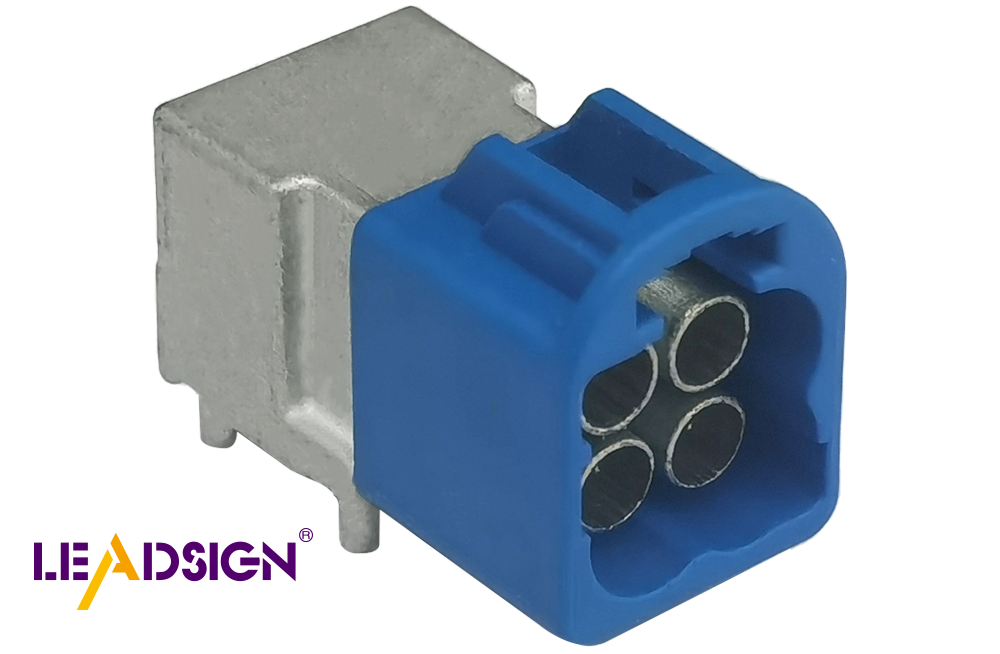

LEADSIGN HSD Connector

The LEADSIGN HSD Connector is known for fast data and tough design.

Mechanical Properties

The LEADSIGN HSD Connector has features that make it a top pick:

Primary and Secondary Lock: Keeps connections firm under stress.

Crimp Connection: Ensures good electric links for clear signals.

High Cable Retention Force: Stops cables from coming loose in moving cars.

High Coding Efficiency: Different codes stop wrong links, boosting trust.

Applications

The LEADSIGN HSD Connector fits many uses, showing its flexibility:

Automotive Electronics: Used a lot in cars for electronics jobs.

Telecom Industries: Good for radio stations and telecom use.

Digital Infotainment Electronics: Supports USB 1.0 to 3.0, LVDS, Ethernet, Firewire, GVIF; great for digital setups.

These connectors show how varied automotive electrical connectors types can be. Each one has special traits to fit the changing needs of the car world.

Comparing Connectors

Temperature Handling

Car connectors need to work in different temperatures. This keeps them reliable and working well in many places.

How We Compare

Temperature Range: Connectors work best in certain temperatures. T2 connectors work from -40 to 100℃. T5 connectors can handle up to 175℃. Choose the right one based on where the car is used.

Durability: Check if a connector lasts through many plug-ins and pull-outs. This helps it stay strong over time.

Physical Strength

Physical strength shows how connectors do under pressure. It makes sure they stay safe and working in tough car spots.

How We Compare

Plug-in Cycles: See how many times a connector can be plugged and unplugged without breaking. Good ones last long, keeping cars running well.

Power Needs: Different connectors use different amounts of power. Knowing this helps pick the right one for each car job.

Following Rules

Following rules means connectors are safe and work well. It's important for making sure car systems are reliable.

USCAR 2 Rules

Testing Performance: USCAR 2 has tough tests for car connectors like shaking, salt spray, and heat changes.

Being Reliable: Meeting USCAR 2 rules means connectors are top quality, keeping cars safe and working right.

By looking at these things, people who work with cars can choose the best connectors. Knowing these differences makes car electrical systems better and more reliable.

Car connectors are key for good vehicle performance. They need to handle tough conditions like heat and shaking. Picking the right connector means looking at temperature limits, strength, and following rules.

See Also

Exploring HSD Connectors in the Auto Sector

Significance of Fakra Connectors in Today's Cars

Benefits of HFM Connectors in Auto Sector