Automotive Electrical Connectors Types: Breaking the Norm

Automotive electrical connectors types are crucial components in modern cars. They play a vital role in transmitting power and data essential for the proper functioning of car systems. These connectors facilitate communication between various parts, ensuring seamless operation. Without them, cars would experience functionality issues. Their design is tailored to accommodate different electrical requirements, prioritizing safety and efficiency. They are engineered to maintain robust connections, preventing disruptions caused by vibrations or environmental conditions. Understanding the significance of automotive electrical connectors types highlights the sophistication and dependability of today's car technology.

Types of Automotive Electrical Connectors

Car electrical connectors are key parts in vehicles. They help move power and data between systems. This part looks at different connector types, showing what makes them special and how they are used.

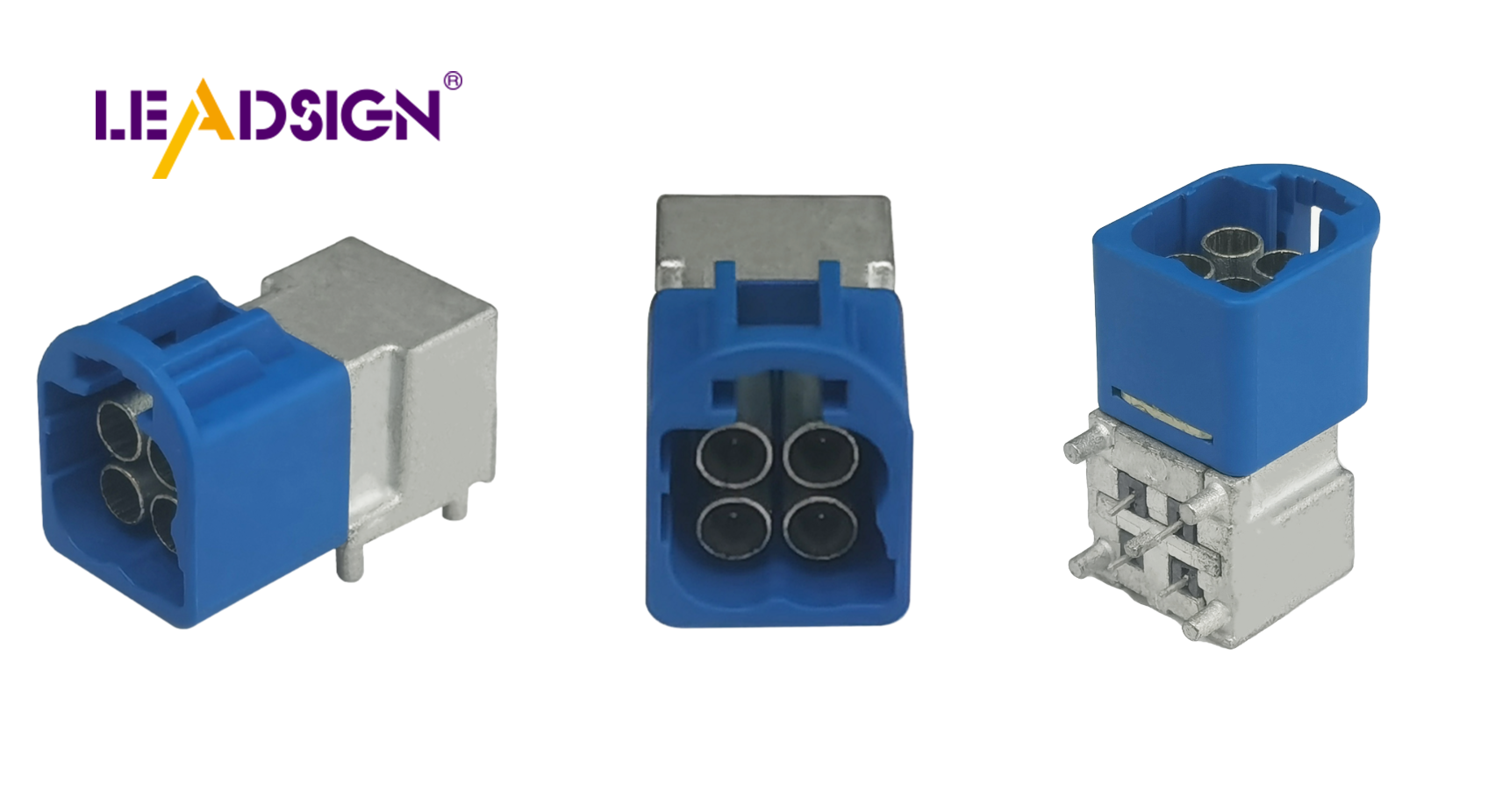

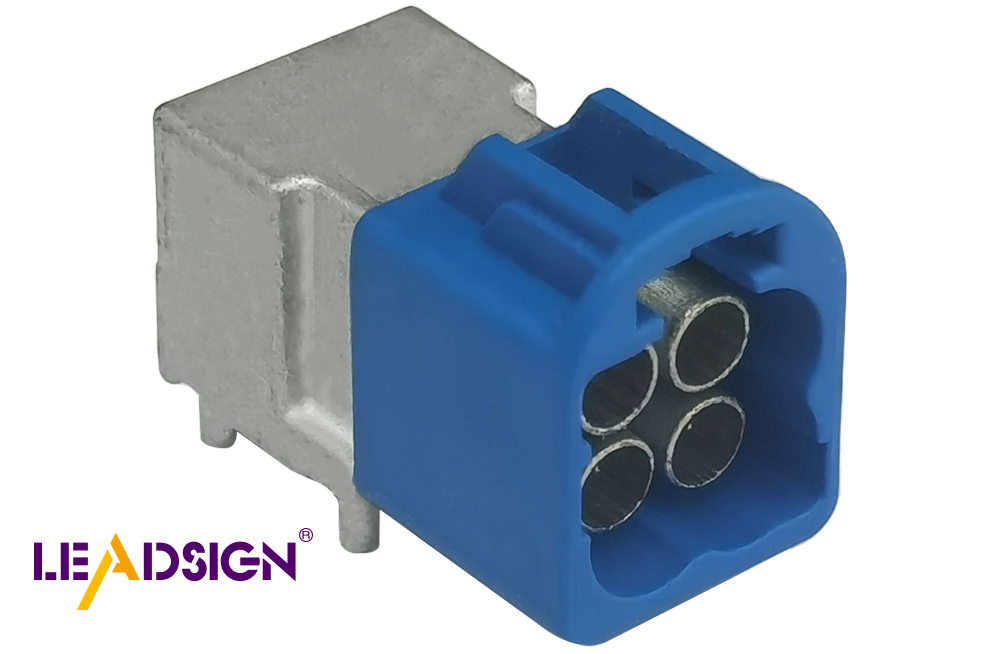

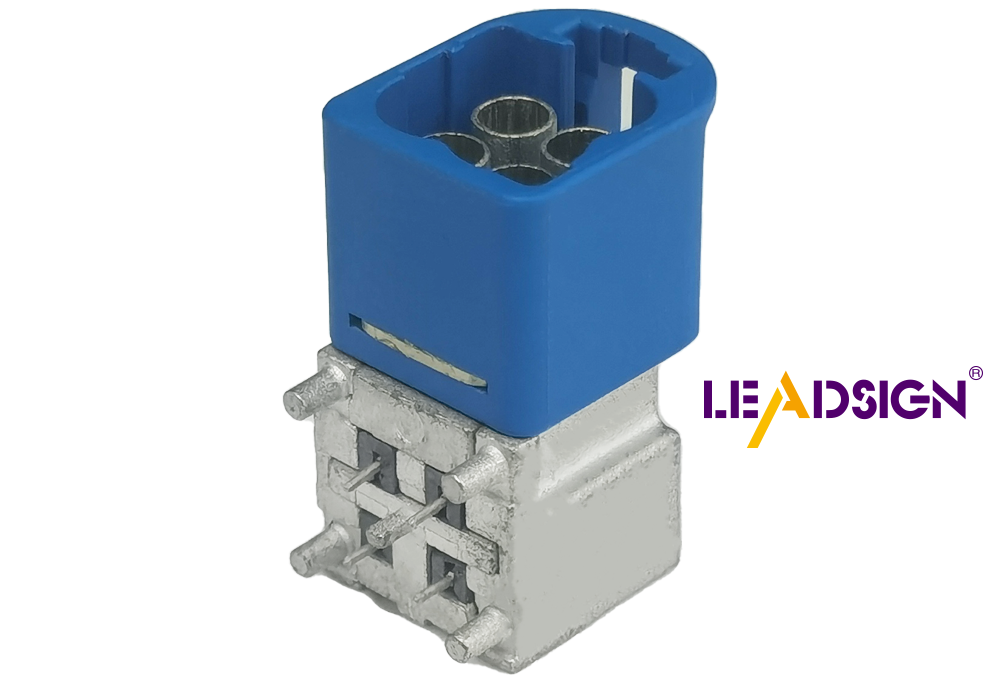

Multi-Pin Sealed Connectors

Features and Uses

Multi-pin sealed connectors keep dirt and water out. They have many pins inside a closed cover to stay clean. These are used in tough places like engines and outside lights.

Advantages in Automotive Applications

In cars, these connectors have many benefits. They stay connected even with shaking or heat changes. Their strong design means less fixing is needed. They keep the car's electric parts working well and safely.

Terminal Connectors

Specific Uses in Vehicles

Terminal connectors join wires without needing to melt them together. They're used where quick links are needed, like battery spots. These help spread power through the car easily.

Design and Functionality

Terminal connectors are simple but work well. A metal piece holds the wire tight for a good link. This makes them easy to put on or take off, great for when things need fixing often.

Power Connectors

Role in Power Distribution

Power connectors send electricity around the car. They link main units to switches and special parts like antennas. These make sure all systems get enough power.

Key Characteristics

Power connectors can handle lots of electricity because they're built strong. They're made for big electric jobs in cars, staying reliable over time.

Technical Aspects of Connectors

Mechanical Properties

Durability and Reliability

Car connectors need to be tough. They deal with shaking, heat, and wetness. Makers build them to handle these problems. Strong materials and tight locks keep them working well. Good connectors last long without needing fixes often. They help stop electric problems in cars.

Material Considerations

Choosing the right stuff is key for connectors. Engineers pick strong, rust-proof materials. Metals like copper and aluminum are common because they carry electricity well. Plastic covers shield metal parts from harm outside. The best material mix makes connectors last longer and work better.

Performance Standards

USCAR-20 Standards

USCAR-20 rules guide car connector making. These rules make sure they work well in cars. They check things like how well they carry power and stay strong. Following USCAR-20 means connectors can meet car needs safely.

Safety and Compliance

Safety is very important in car design. Connectors must follow safety rules to avoid accidents. Good insulation and tight links lower the chance of shorts happening. Meeting industry standards keeps connectors safe for cars and people inside them.

Applications of Automotive Connectors

Car connectors have many uses. They help move power and data in cars. This is important for today's car systems. Let's see how they are used, especially for fast data transfer.

High-Speed Data Transmission

What HSD Connectors Do

HSD connectors are key in car electronics. They handle fast data streams well. These work with cameras, USBs, and other tech gadgets. Their strong design makes them reliable in tough spots.

Why They're Important

In car electronics, HSD connectors help parts talk to each other fast. They make sure data moves quickly for smart driving tools and fun features. By keeping connections steady, they make cars safer and better.

Other Cool Uses

Fun Car Systems

Fun systems in cars need these connectors a lot. They join screens, sound systems, and maps together. This helps everything work smoothly so users enjoy their ride more. Good connectors mean fewer problems.

Wireless Stations

These connectors also work in wireless stations outside the car. They help send signals and keep talks clear. Built strong, they can handle bad weather too. By staying connected well, they make networks more reliable.

Future Trends and Innovations

The world of car connectors is changing fast. As tech grows, new ideas change how these connectors work in cars.

Design Innovations

Smaller and Better

Engineers make connectors tiny and smart. Small parts fit in tight spaces, important for tech-filled cars today. Tiny connectors weigh less, helping cars use less fuel. They also work better by saving energy when sending power. This shows the push for small and smart designs.

Better Connections

Better connections are key now. Engineers create connectors that send data faster. These help car systems talk smoothly to each other. They also make links stronger, so they don't break easily. By improving connections, car connectors help make smarter cars.

Breaking the Norm

New Tech Ideas

New tech is changing connector design rules. Ideas like new tech ideas wireless and smart connectors are growing popular. Wireless ones cut down on wires, making things neat and less likely to fail. Smart ones can find problems and talk with car systems, giving real-time info on how things are working. These new ideas change how connectors do their job.

Big Changes for Cars

These new ideas change the car world a lot. Cool connectors let cars have features like self-driving and cool sound systems. They help electric cars by spreading power well. As car connectors grow better, they push the industry towards safer, smarter, and more connected futures.

Car connectors are very important in today's vehicles. They help send power and data reliably, making cars work better. New designs in connectors bring big improvements. Smaller and smarter connectors make things work faster and connect better. These changes lead to more advanced car technology. As cars change, connectors will keep helping them be safer and more efficient. The future of car connectors is bright, with the chance to change how cars work and make driving more fun.

See Also

Exploring the Power: Fast FAKRA-Mini Connections in Auto Sector

Discovering the Benefits of Small Fakra Connectors in Cars

Enhancing Car Data Transfer: Innovative Connections and Wires

Understanding HSD Connections in Auto Sector

Transforming Car Connections: The Benefits of HFM Connectors