What You Need to Know About Automotive Electrical Connectors Types

In cars, electrical connectors are very important, especially the various car wire connector types. They help parts communicate and share power efficiently. Your car relies on these connectors to function properly. As automotive technology advances, the demand for better connectors increases. The market for car wire connector types is projected to grow by 5.8% annually until 2026, highlighting the significance of understanding these essential components in modern vehicles.

Basics of Automotive Electrical Connectors

What They Are and Do

Car electrical connectors are like the veins of your car. They let power and signals move between parts easily. Without them, your car wouldn't work well.

How They Help Your Car

Connectors in cars join different parts like the engine and lights. This helps them talk to each other and work together. It makes sure your car runs safely.

Why Good Connections Matter

Good connections keep your car working right. If a connector is loose, things can break, like headlights or starting the car. Keeping connectors tight is important for a reliable car.

How They Changed Over Time

Car connectors have changed a lot over years. Knowing this helps you see how cool today's technology is in cars.

First Changes

In the 1950s, plug and clamp connectors came out. They made it easier to connect car parts. This was big for making modern cars work better.

New Ideas Today

Now, new ideas keep changing car connectors. Fancy cars use wireless ones instead of metal ones with radio waves now. This makes connections better and helps smart cars grow too. Learning about these changes shows where car tech is going next.

Car Wire Connector Types

Knowing car wire connector types helps fix your car. These connectors make sure your car's electric parts work well. Let's look at different types by design, job, and use.

By Design

Design shows how connectors fit in your car. Here are two designs:

Blade Connectors

Blade connectors are flat like a knife. They are common in cars because they connect well. They slide into slots for a tight fit. This stops them from coming loose when the car moves.

Pin Connectors

Pin connectors have round pins that fit into sockets. They work in many car systems. Their shape makes them easy to connect and disconnect, good for places needing lots of checks.

By Function

A connector's job decides its role in the car's system. Here are two main jobs:

Power Connectors

Power connectors move electricity between parts. They are key for things needing steady power like engines and lights. Keeping these working is important for your car.

Signal Connectors

Signal connectors send data between electronic parts. They help modern cars where systems talk to each other. Good signal connectors keep things like music and maps working smoothly.

By Application

Different uses need special connectors for their needs. Here are two uses:

Engine Compartment Connectors

Engine compartment connectors handle tough conditions like heat and fluids. They link important parts like sensors so the engine works well. Checking them often stops engine problems.

Interior Connectors

Interior connectors join inside parts like dashboards and seats together easily. Keeping them good ensures everything inside works right.

Knowing these connector types helps you fix and care for your car's electric systems better as tech grows.

Installation Techniques

Tools Needed

To put in car connectors right, you need good tools. These tools make sure connections stay strong and safe.

Crimping Tools

Crimping tools help join connectors to wires by squeezing them tight. This makes a strong hold so wires don't slip out. Pick a crimping tool that fits your connector size for best results.

Soldering Gear

Soldering gear is key for making lasting connections. It melts solder around the wire and connector to make a solid link. This way is great for connections needing extra strength.

Step-by-Step Guide

Putting in connectors right keeps your car's electric system working well. Follow these steps to do it correctly.

Getting Wires Ready

Take Off Insulation: Use a wire stripper to cut off about half an inch of the cover from each wire end. This shows the metal inside needed for connecting.

Twist Wire Strands: If the wire has strands, twist them together tightly. This stops fraying and makes a neat connection.

Add Grease: Before connecting, put some dielectric grease on the bare wire. This grease stops water and rust, keeping the connection long-lasting.

Making Connection Secure

Put Wire In: Place the stripped wire into the connector snugly with no strands outside.

Crimp or Solder: Use your crimp tool to squeeze the connector onto the wire or heat and add solder until it covers smoothly if soldering.

Check Connection: Make sure the wire is tight with no loose strands; it should not come apart when gently pulled.

Cover Connection: Use heat shrink tubing or tape to wrap up the joint for extra protection from weather.

By following these steps, your car's electrical connectors will work well and last longer.

Common Problems and Fixes

Solving Usual Issues

Car electrical connectors can have problems that affect how they work. Knowing these helps you keep your car's electric parts working well.

Loose Connections

Loose connections often cause car electrical issues. If connectors aren't tight, electricity can't flow right. This might make lights not work or cause engine trouble. To fix, make sure all connectors are tight. Check them often for looseness and tighten if needed.

Rusting

Rust is another problem for connectors. It happens when water and dirt mix, causing rust to form. This can stop electricity from flowing and cause failures. To stop rust, use protective grease on connectors. Nye's Connector Grease works well to stop short circuits and keep things working right in many electronics. Look at connectors often for rust signs and clean them quickly.

Care Tips

Taking care of electrical connectors keeps your car running well. Here are some tips to keep them good.

Regular Checks

Checking often helps find problems before they get bad. Look at connectors for wear, damage, or rust signs. See if wires or connectors are loose and need tightening. Doing this regularly stops sudden failures and keeps your car's electric system reliable.

Cleaning Steps

Keeping connectors clean helps them last longer. Dirt can build up over time and hurt how they work. Follow these steps to clean:

Turn Off Power: Make sure power is off before cleaning to stay safe.

Brush Away Dirt: Use a soft brush to gently remove dirt from the connectors.

Use Cleaner: Spray special cleaner on stubborn dirt on the connectors.

Wipe Dry: After cleaning, wipe with a dry cloth.

Add Protective Grease: Once clean, put a thin layer of grease like Nye's Connector Grease to stop future rusting.

By following these tips, your car's electrical parts will stay in great shape and work well for years.

Frequently Asked Questions

How to Pick the Right Connector?

Picking the right connector is important for your car. Follow these steps:

Know the Use: Find out what you need the connector for. Is it for power, signals, or a special part like the engine? Knowing this helps you choose better.

Check Fit: Make sure it fits your car's system needs. Look at things like voltage and how tough it needs to be.

Think About Style: Choose between blade or pin designs based on space and ease of use.

Look at Strength: Pick strong connectors that can handle heat, wetness, or shaking.

Ask an Expert: If unsure, talk to a pro or check your car's guide.

These steps help you pick a connector that works well and lasts long in your car.

What if There's a Bad Connection?

Fixing bad connections can be annoying but doable with these steps:

Find the Issue: Look for signs like flickering lights or parts not working.

Check the Connector: See if it's damaged, rusty, or has loose wires.

Tighten It Up: If it's loose, make it snug using proper tools.

Clean Rusty Spots: Clean rust with cleaner and brush; add grease after cleaning to stop more rusting.

Swap Broken Connectors: Replace broken ones with new matching ones.

Test It Out: After fixing, test to see if everything works fine now.

By fixing bad connections fast, you keep your car safe and working well.

Automotive electrical connectors are crucial in cars today. They help car parts talk to each other, making cars safer and work better. Knowing about them helps you fix and care for your car's electric systems. As technology grows, learning about connectors and how to keep them good is important. If you're curious or need help, ask questions. Your interest helps make new ideas in car tech happen.

See Also

Exploring HSD Connectors in the Auto Sector

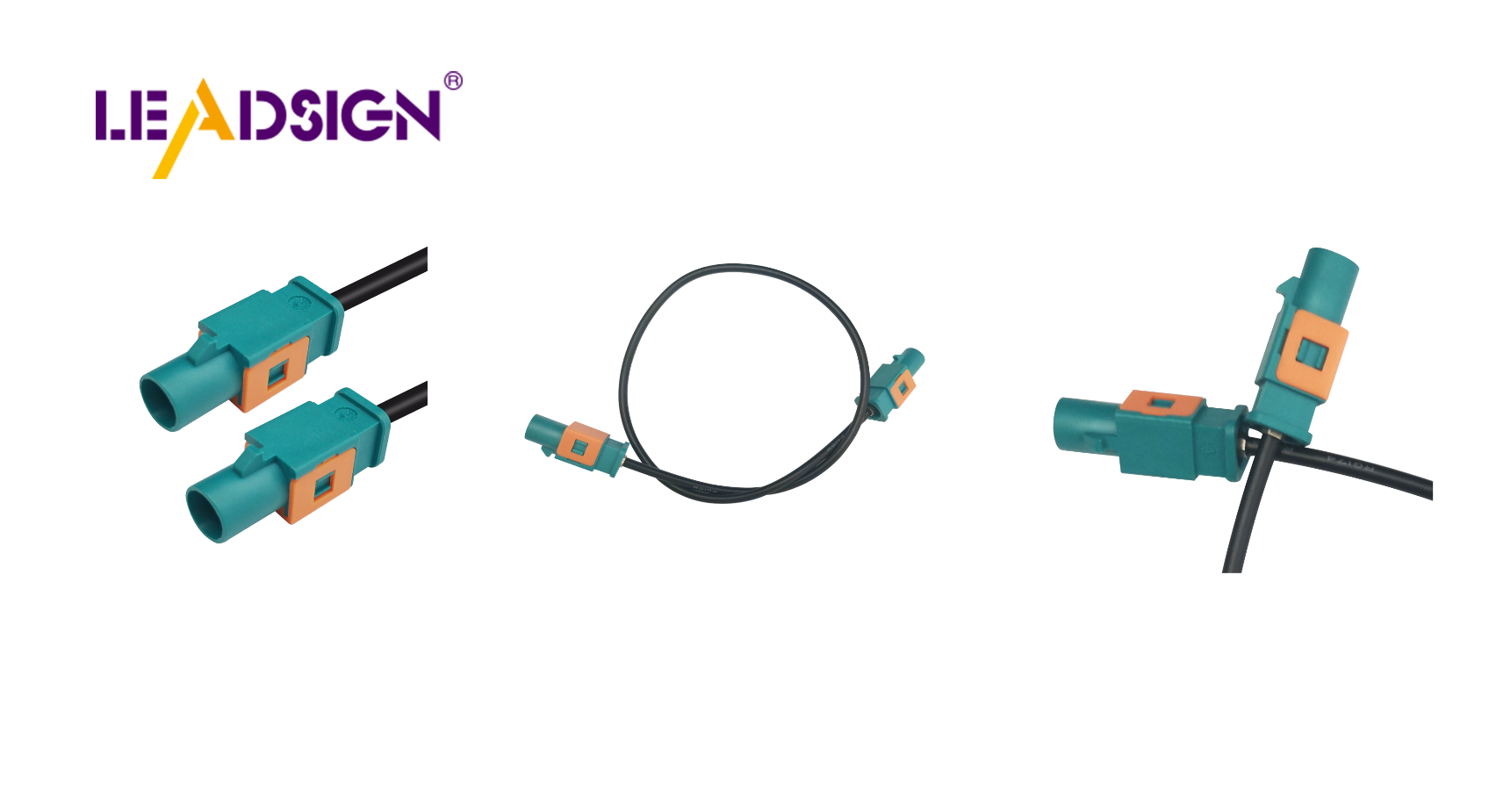

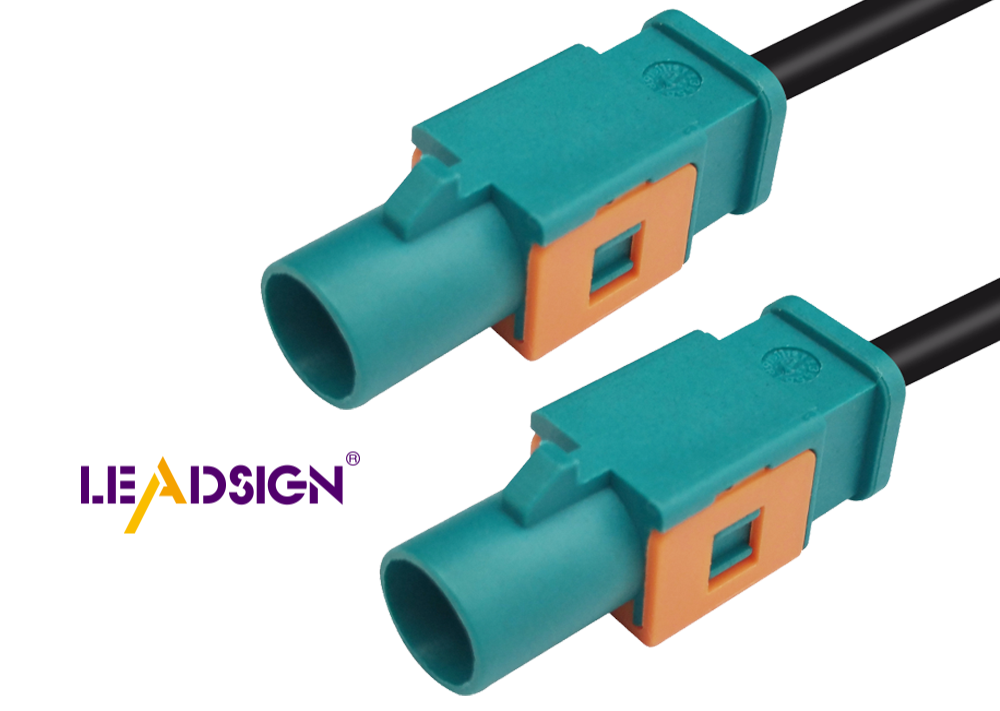

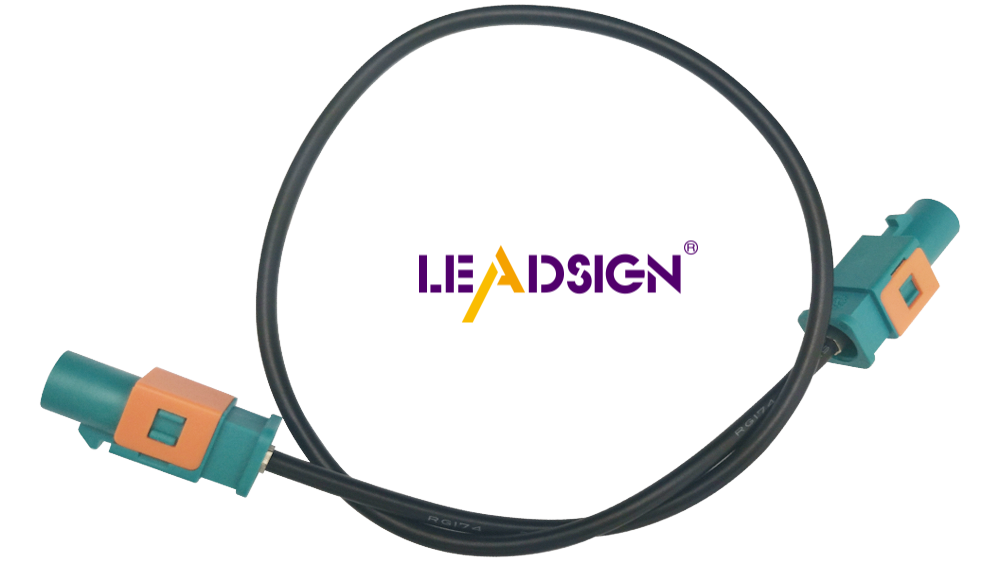

Significance of FAKRA Connectors in Contemporary Cars

Vital Role of FAKRA Connectors in Auto Uses