Automobile Electrical Connectors: Boosting Engineer Confidence

Automobile electrical connectors play a crucial role in modern vehicles. They are essential for ensuring the safety, reliability, and compatibility of various systems. Selecting the right connectors can be challenging for engineers due to weather and fit issues. The market for automobile electrical connectors is growing at a rate of 5.8% annually, highlighting their increasing significance. Original equipment manufacturer (OEM) connectors are durable, cost-effective, and offer long-term benefits. Understanding these components not only boosts engineers' confidence but also enhances car performance.

Understanding Automobile Electrical Connectors

Role and Functionality

Basic Functions

Car electrical connectors are key to vehicle electronics. They help connect different electronic parts securely. Engineers use them to send power and signals well. The design of each connector affects how the car works. Good connectors stop problems and keep things safe.

Importance in Vehicle Systems

Connectors are important for joining complex car systems. New cars have tech like infotainment and driver help. Each needs special connectors to work best. Good connectors make sure systems talk easily. OEM connectors fit well and last long, helping cars run strong.

Common Challenges

Environmental Factors

Car electrical connectors face tough weather conditions. Heat changes and wetness can harm them. Engineers pick connectors that handle these issues. OEM ones are made for harsh places. Good seals and materials stop rust and damage.

Compatibility Issues

Compatibility is a big problem when choosing connectors. Engineers must ensure they fit with current systems. Wrong fits can cause failures and waste energy. OEM connectors solve this with great compatibility standards, fitting smoothly into OEM systems for steady performance.

Spotlight on FAKRA HSD Connector

Features and Specifications

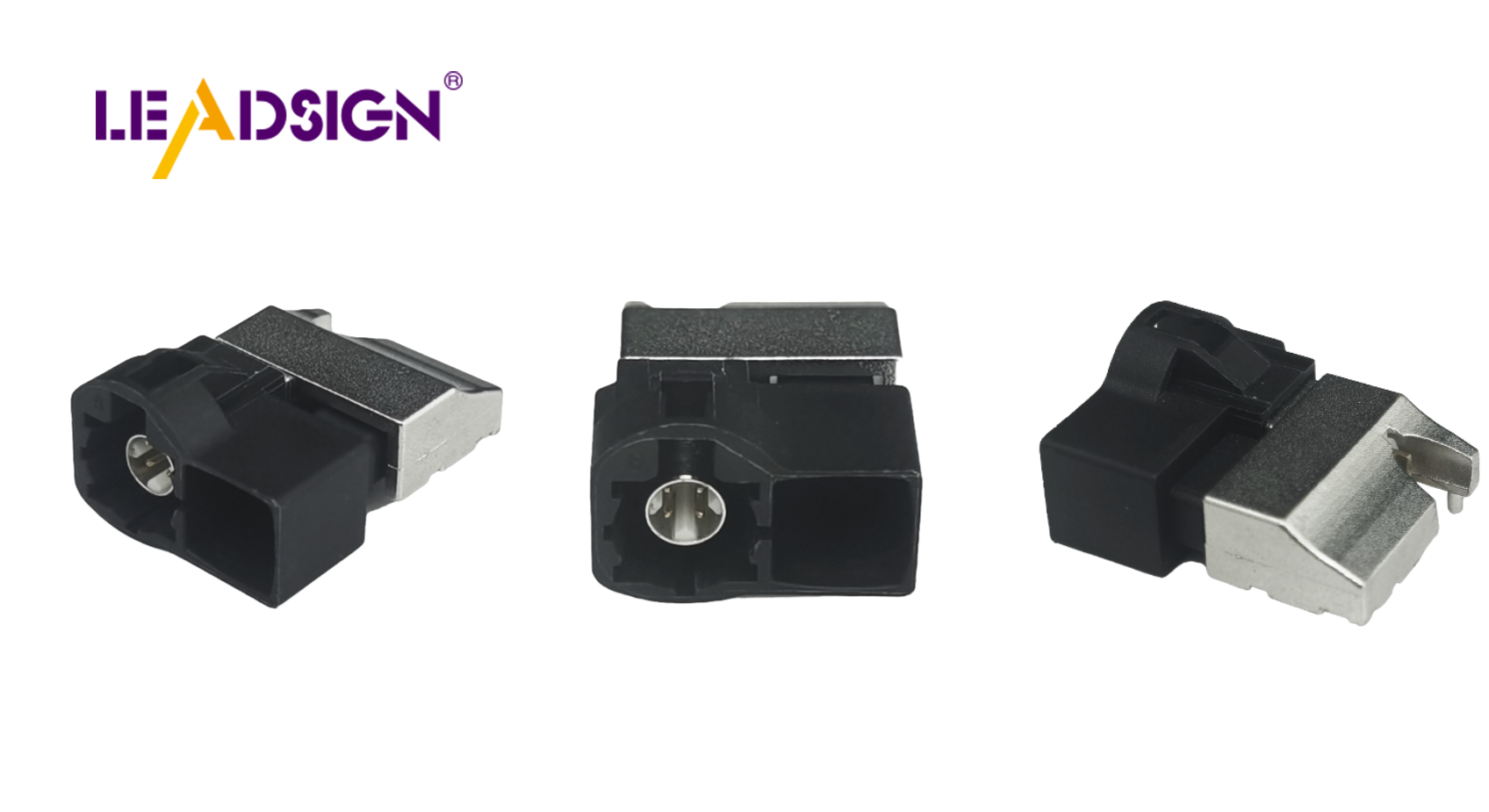

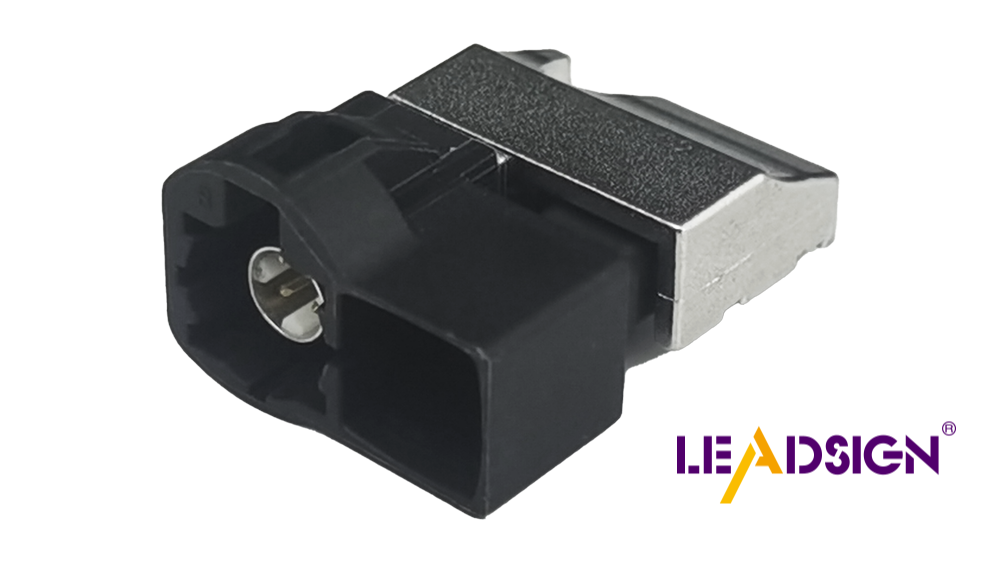

Design and Structure

The FAKRA HSD Connector is special because of its new design. Engineers made it for fast data in cars. It has a strong 4+4 pin setup. This makes sure connections are safe in car systems. Its right-angle shape helps easy fitting on boards and panels. Different colored plastic covers stop wrong connections. These covers fit car rules, making sure they connect right.

Technical Specifications

The FAKRA HSD Connector works great technically. It can handle temperatures from -40°C to +105°C. This means it works well in many weather conditions. The system keeps a 100 ohm standard for fast data transfer. It's made to meet RF needs in telematics like SDARS, GSM, and GPS. Its small size and keying make it useful in tight spots.

Advantages Over Other Connectors

Performance Benefits

The FAKRA HSD Connector gives better performance benefits. Fast data transfer is a main feature. It meets the need for quick data in new cars. The design ensures good signal sending, perfect for infotainment systems. It offers a cheap RF interface, following FAKRA and USCAR rules. Engineers trust this connector for steady work.

Reliability and Durability

Reliability and durability are what the FAKRA HSD Connector is known for. It handles tough car environments well. Engineers picked materials that fight rust and harm. Good seals keep moisture out, ensuring long-lasting use. OEMs trust it for its fit with current systems, boosting engineer confidence.

Practical Uses in Car Systems

Entertainment Systems

Connection Solutions

Car electrical connectors are crucial for entertainment systems. Engineers use them to connect audio, video, and maps smoothly. Good connectors make data move fast and work well. This makes driving more fun. INOAC's success with outside options shows how important good connectors are. New car models sell better because of strong connection solutions.

Better User Experience

Car electrical connectors make using entertainment systems easier. Engineers pick ones that send data quickly. This helps touchscreens and voice commands work better. Right connectors stop delays and make things respond faster. Webasto-Edscha Cabrio shows how well they fit in cars. This proves quality connectors boost user happiness.

Driver Help Technologies

Safety Parts

Safety parts in new cars need car electrical connectors a lot. Engineers link sensors and cameras to control systems with them. This keeps data flowing right for lane warnings and cruise control. Good connectors stop signals from dropping, making things safer. OEM connectors fit well and install easily, keeping safety systems running smoothly.

Joining with Car Systems

Joining driver help tech needs exact car electrical connectors. Engineers want ones that fit into car systems perfectly. This helps automatic brakes and crash avoidance work together well. Right connectors make sure these features do their job right. Webasto-Edscha Cabrio works with almost all car makers worldwide, showing how key good connector joining is for safety.

Customization and Support by LEADSIGN

Customization Options

Tailored Solutions

LEADSIGN gives special solutions for car connectors. The LEADSIGN-FAKRA PCB Connector offers custom choices for needs. Engineers pick from setups for best work. It has a B type setup and is white, good for high-frequency use. There are 13 color codes and one neutral code. This helps engineers find the right match.

Flexibility in Design

Design flexibility is key for car connectors. LEADSIGN offers many design choices to fit needs. Engineers can change connectors to match projects. Changing designs helps them fit into car systems well. This makes vehicle electronics work better and last longer.

Integration Support

Technical Assistance

LEADSIGN gives help to use car connectors well. Engineers get tips on picking the right ones. They offer advice on fitting and working issues. This help makes sure connectors work well in cars. Engineers trust LEADSIGN for full support during projects.

Project Implementation

Project work needs good planning and doing. LEADSIGN helps put connectors into designs fast. They give quick delivery and great support for smooth use. Engineers can try free samples, just pay shipping, before using more widely. Many shipping ways meet project needs on time.

The FAKRA HSD Connector is great for cars. It helps engineers feel sure with strong data links and tough design. This connector works well in bad weather and keeps connections safe. LEADSIGN lets you change it for special projects. Think about using the FAKRA HSD Connector in your car work. It improves systems with fast data and lasting strength.

See Also

Unleashing Potential: High-Performance FAKRA-Mini Connectors for Automotive Sector

Discovering Advantages of FAKRA Auto Connectors

Improving Auto Communication Using FAKRA PCB Connectors

Boosting Data Transfer: Significance of High-Speed Auto Connectors