How Auto Wiring Affects Signal Integrity in High-Speed Designs

Signal integrity is crucial in high-speed PCB designs. Engineers put in a lot of effort to ensure signals do not fail. They conduct numerous tests and utilize specialized connections. High-Speed PCB Design requires close monitoring of electrical signals, which can degrade at high speeds. Reflections occur when connections are not well-matched, leading to significant issues. Automotive wiring impacts these designs by altering signal degradation and interference. Ensuring seamless operation from beginning to end guarantees optimal performance.

Understanding Signal Integrity in High-Speed Designs

Key Factors Affecting Signal Integrity

Maximum Frequency and Rise Time

Maximum frequency and rise time are very important. Engineers must think about these for good performance. High frequencies can mess up signals. Rise time is how fast a signal goes from low to high. Fast rise times need careful planning to stop problems like echoes.

Data Transfer Rates and Their Impact

Data transfer rates affect signal integrity a lot. As speeds go up, keeping signals clear gets harder. Fast data can ruin signals, causing mistakes. Engineers design circuits to handle these speeds well. Good layout and picking the right parts help fix this.

Complexity in High-Speed Design

Component and Routing Density

More parts and close wiring make designs complex. Many parts can cause interference. Engineers plan layouts to reduce noise and interference. Tight designs need exact control of trace lengths for good signals.

Interface Types and PCB Technology

Interface types and PCB tech also matter for signals. Different interfaces need special care, like USB or Ethernet. Engineers pick the right PCB tech for these needs. New materials help manage signal issues well.

The Role of Auto Wiring in Signal Integrity

How Wiring Affects Signals

Transmission Line Problems

Auto wiring is key to keeping signals strong. Engineers think about how signals move in wires. If not matched, signals can bounce back and get lost. Good wiring stops these problems, keeping signals clear.

Blocking Interference and Crosstalk

Electromagnetic interference (EMI) and crosstalk are big issues. Auto wiring must be planned well to stop them. Shields and space between wires help block bad interference. By managing EMI and crosstalk, signal sending gets better.

Planning for Auto Wiring

Controlling Impedance and Using Two Wires

Impedance control is important for good auto wiring. Engineers match impedance to cut down on signal loss. Using two wires for a signal helps cancel noise. This makes communication strong.

Picking Materials and Placing Parts Right

Choosing the right stuff and placing parts smartly is crucial. Engineers pick materials that work with fast signals and resist damage. Good part placement cuts interference, making paths better for signals.

Case Studies:

Zero-failure Signal Integrity: Minnesota Wire used a special process with regular connectors. This made connections stronger, boosting both strength and signal quality.

Strong EMI Testing: With custom solutions, Minnesota Wire beat OEM needs, showing how special designs keep signals good.

These stories show why careful design and testing make circuits work well at high speeds.

High-Speed PCB Design and Data Connectors

HSD Connectors' Importance

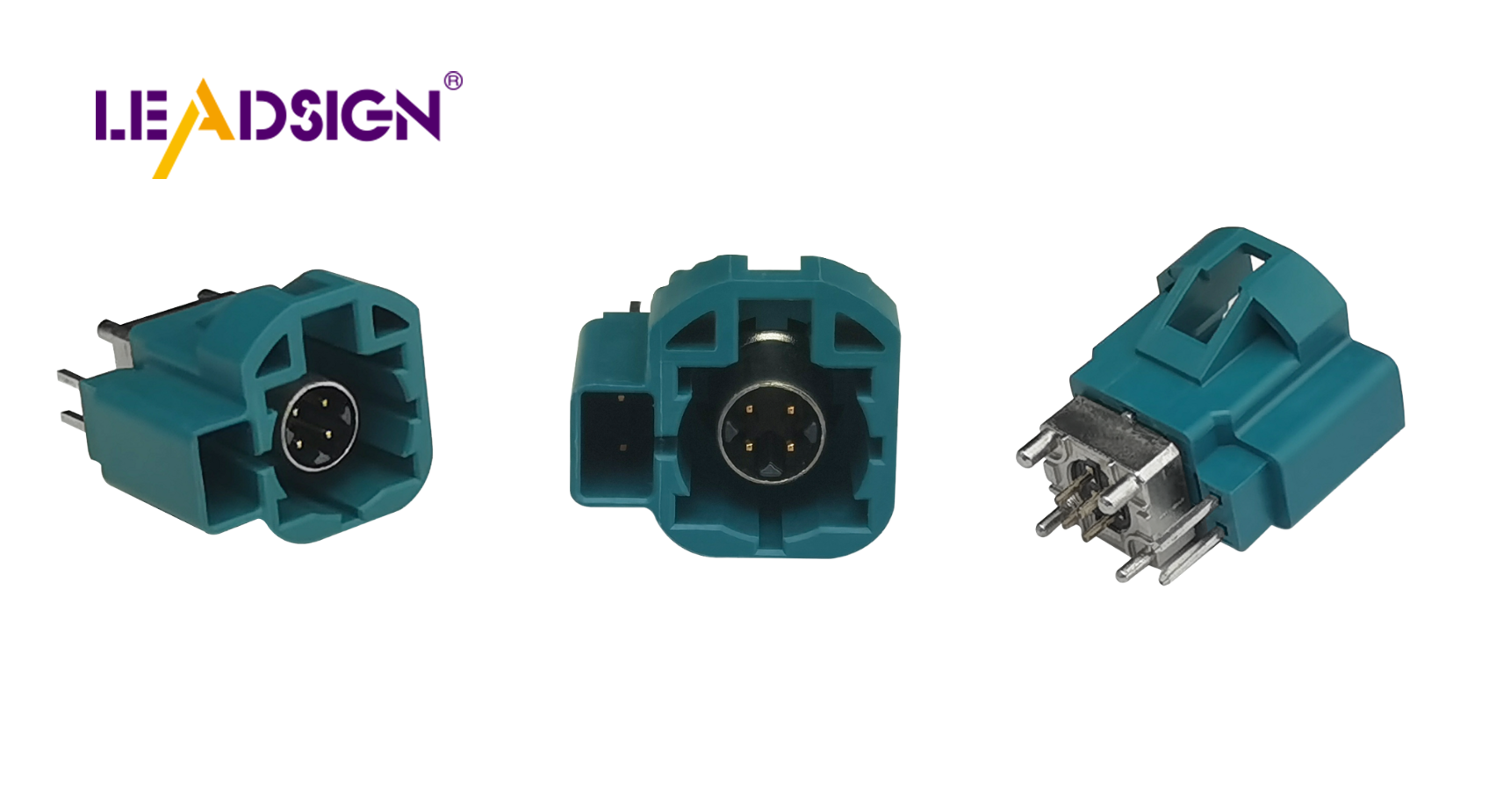

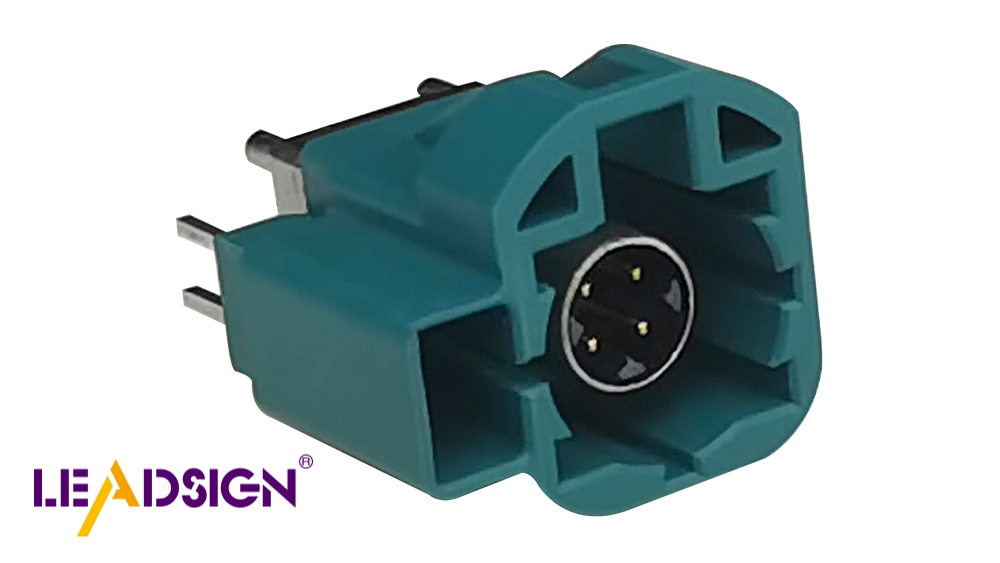

High-Speed Data (HSD) connectors are vital for keeping signals clear in fast PCB designs. They are made to handle modern car electronics, making sure signals stay strong even when data moves quickly.

Protocols and Certifications

HSD connectors follow rules to work well. They fit many uses like USB 1.0, 2.0, 3.0, LVDS, Ethernet, and IEEE 1394. By following these standards, they ensure strong connections for each use.

Use in Car Electronics

In cars, HSD connectors are very important. They are used for things like cameras and music systems. Their design includes special features that make them easy to use in cars. Some have extra power pins for more uses.

PCB Connectors' Role

PCB connectors matter a lot in fast PCB designs because they affect signal quality directly. They connect different parts of a circuit without losing signal strength.

Connector Types and Uses

There are many kinds of PCB connectors for different jobs. Board-to-board ones join two PCBs; wire-to-board ones link wires to a PCB. Each type is good for certain tasks like tight spaces or strong links.

Design Challenges and Fixes

Making connectors for fast speeds is hard. Engineers must fix problems like echoes and weak signals by choosing the right materials and designs that keep signals strong in fast places.

Keeping signals clear in fast designs is very important. Engineers work on car wiring and connectors to make strong circuits.

Signal Integrity: Fast data needs exact connections to stop mistakes. Good design stops problems like echoes and changes in signals.

Role of Auto Wiring: Good wiring cuts down on interference, making signals clearer. Special solutions, like from Minnesota Wire, go beyond usual needs, making everything work better.

By focusing on these parts, engineers can build reliable fast circuits needed for today's cars and electronics.

See Also

Maximizing Automotive Data Transfer: High-Speed Connector Significance

Benefits of Fast Data Transfer in Auto Technology

Improving Auto Data Transfer: Enhanced Connectors and Cables