How Auto Wire Connector Types Meet Performance Standards

Automotive electrical connectors types are crucial for ensuring safety and performance in vehicles. These connectors play a vital role in ensuring the proper functioning of electrical systems in cars. The automotive industry adheres to stringent standards to guarantee the reliability and durability of these components. Complying with these standards is essential for manufacturers to uphold high-quality standards, ultimately leading to safer and more efficient vehicles for consumers. Understanding the various types of automotive electrical connectors underscores their significance in maintaining the optimal condition of vehicles.

Understanding Car Electrical Connectors Types

Car electrical connectors are important in today's cars. They help different electrical parts work well together. This part talks about common and special connector types, showing their features and uses.

Common Car Electrical Connectors Types

Blade Connectors

Blade connectors are used a lot in cars. They have a flat piece that fits into a slot. This makes connecting easy and safe. You find blade connectors in fuse boxes where they must work well.

Ring Connectors

Ring connectors go around bolts or studs to connect things safely. They are used for grounding and battery connections. The ring shape keeps them from coming loose when the car moves.

Butt Connectors

Butt connectors join two wires together end-to-end. They fix or extend wire groups. By squeezing them onto wires, they make strong connections. These keep car electrical systems working right.

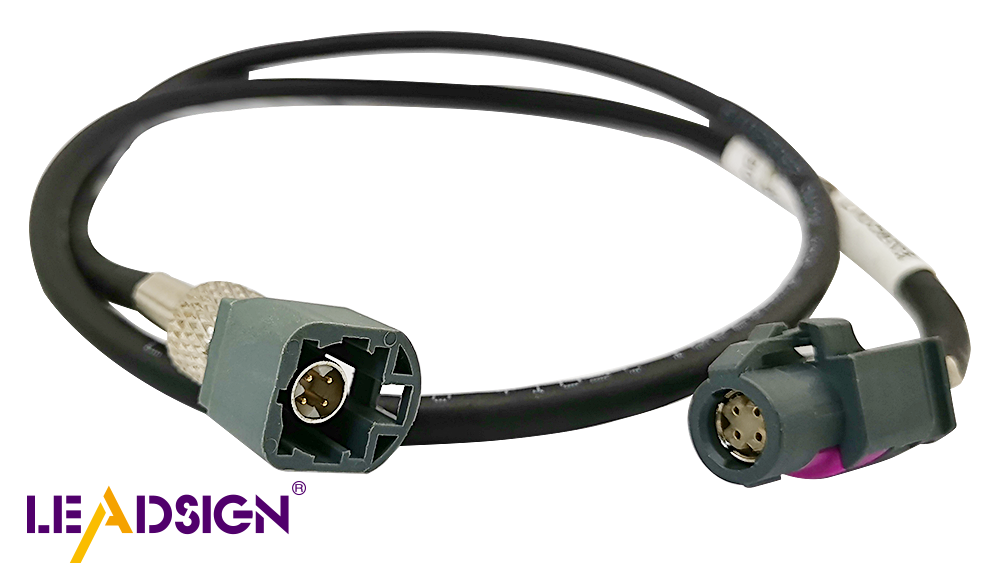

Special Car Electrical Connectors Types

Waterproof Connectors

Waterproof connectors keep water out of connections. They are needed where it's wet, like near engines. These have seals to stop water, making them last long.

High-Temperature Connectors

High-temperature connectors handle lots of heat. They're used near hot engines or exhausts. Made from tough materials, they don't melt easily, keeping connections safe even when it's really hot.

Performance Standards for Auto Wire Connectors

Car wire connectors need to meet rules for safety. These rules help make sure connectors work well in different conditions.

Key Standards and Certifications

ISO Standards

ISO sets global rules for car wire connectors. These rules check things like strength and heat resistance. Following ISO means connectors work well in tough spots.

SAE Standards

SAE gives more important rules for car wire connectors. Rules like USCAR 2 test how connectors handle heat and shaking. Meeting SAE standards shows the connectors are good quality.

Testing Procedures

Testing checks if car wire connectors follow the rules. Tests see how they work in different situations.

Electrical Testing

Electrical tests check if wires carry power well. They make sure connections stay strong without losing energy.

Mechanical Testing

Mechanical tests see if wires can handle pulling and twisting. Passing these tests shows they stay connected under stress.

Environmental Testing

Environmental tests look at how wires do in hot, wet, or rough places. These tests prove the wires work no matter what happens outside.

Meeting and Exceeding Standards

Car wire connectors need to do more than just meet rules. They must be even better for cars to work well. Makers focus on design and quality checks.

Design Considerations

Material Choice

Makers pick materials that make connectors strong and reliable. They choose ones that don't rust, handle heat, and keep power flowing. Copper is often used because it works well in tough spots. Picking the right stuff helps connectors work in any condition.

Connector Shape

Connector shape is key for meeting rules. Engineers make them easy to install and stay connected. They add locks so they don’t come apart by accident. Connectors fit different wires, making them useful in many car parts. Good designs keep connections stable, even when things get rough.

Quality Checks

Making Controls

Makers use strict controls to keep connector quality high. They use smart machines to make sure everything is made right. Machines watch each step and fix mistakes fast. This way, connectors always meet or beat what’s needed.

Checking and Testing

Checking and testing are big parts of quality checks for connectors. Makers look closely for any problems or mistakes. They run tests like electrical, pulling, and weather tests to see how connectors hold up in different places. These steps make sure only the best connectors go out to buyers.

Meeting rules is important for car wire connectors. These rules keep them safe and reliable, making everyone feel secure. By following these rules, connectors stay strong in different situations, helping cars work better.

In the future, new ideas in car connector technology will make them even better. Things like fast data connectors and stronger materials will change car electronics. This will help cars stay safe and work well as things change in the industry.

See Also

Essential HSD Connectors in Automotive Technology

Significance of HSD Connectors in Automotive Sector

Enhancing Performance with HFM Connectors in Auto Industry

Benefits of HFM Connectors in Automotive Sector

Improving Auto Data Transfer: Cutting-Edge Connectors and Cables