Essential Advice for Working with Automotive Plugs and Connectors

Car plugs and connectors are key to your car's electrical system. They help send power and data between important parts like headlights. Picking the right auto wire connector types is very important for safety. Good connectors prevent electrical problems and keep lights and brakes working well. Knowing how they work helps you fix and care for your car better. This keeps your car running safely and reliably for a long time.

Key Takeaways

Understand your car's make and model to choose the right connectors for its electrical needs.

Always follow the manufacturer's recommendations for connector types to ensure optimal performance.

Select connectors that match the wire gauge precisely to prevent overheating and connection issues.

Use high-quality connectors to enhance reliability and reduce the risk of electrical problems.

Regularly inspect and clean connectors to maintain their performance and longevity.

Utilize the right tools, such as wire strippers and crimping tools, for proper installation and secure connections.

Replace damaged connectors promptly to avoid costly repairs and ensure your car's electrical system functions smoothly.

How to Pick the Right Auto Wire Connector Types

Choosing the right auto wire connector types keeps your car working well. This section explains how to check your car's needs, learn about connectors, and match them with wire sizes.

Knowing Your Car's Details

Find out your car's make, model, and electrical needs

Each car has different electrical needs. First, know your car's make and model. This helps you understand what kind of electrical system it has. Some cars need connectors for fast data transfer. Others use simple designs. Think about the power load and if it uses AC or DC current.

Follow the maker's advice on connectors

Car makers give helpful tips for choosing connectors. Look in the owner's manual for suggested connector types. These tips ensure good performance and fewer problems. Using them makes your car run better and safer.

Learning About Auto Wire Connector Types

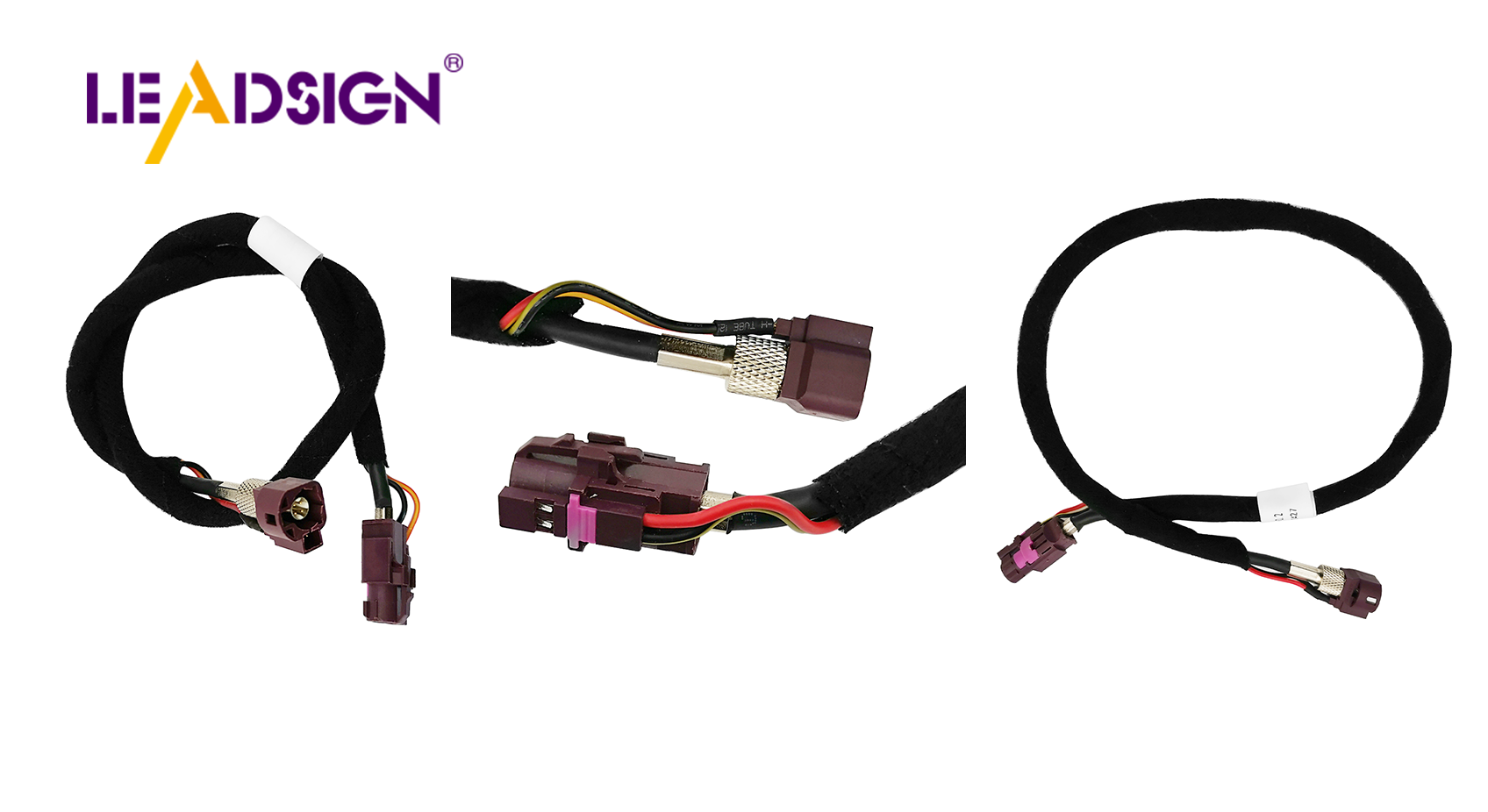

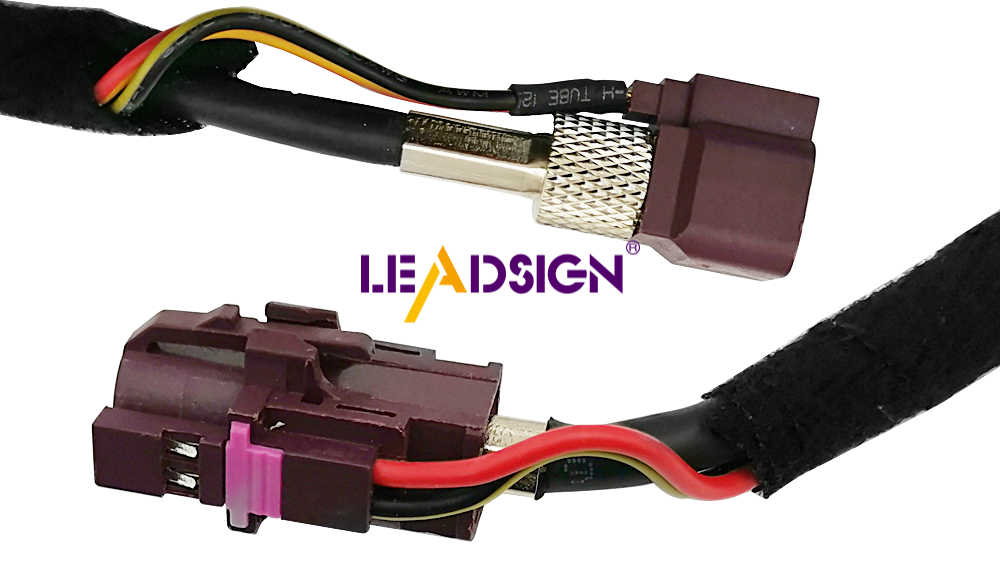

Blade, bullet, and pin connectors

Connectors come in many shapes for different jobs. Blade connectors are flat and easy to use quickly. Bullet connectors fit tightly, great for areas with shaking or movement. Pin connectors work well in complex systems with many wires. Knowing these helps you choose correctly.

Special ones like HSD connectors for fast data systems

Some systems need special HSD (High-Speed Data) connectors for quick data transfer. These are used in cameras or USB ports in cars. They are strong and have locks to stay secure even when conditions are tough.

Pro Tip: Use HSD connectors for things like Ethernet or LVDS systems needing fast data speeds.

Matching Connectors to Wire Sizes

Choose the right size connector for your wire gauge

The connector must fit the wire size perfectly. A wrong-sized connector can cause bad connections or problems like overheating. For example, a 16-gauge wire needs a matching 16-gauge connector.

Avoid wrong matches that may cause problems

Wrong matches can lead to overheating or broken systems. Make sure the connector fits both the wire size and system needs well. Tools like test kits help you match them correctly without mistakes.

Quick Tip: If unsure, ask an expert or use a multimeter to check before deciding.

By knowing your car’s details, learning about different auto wire connector types, and matching them properly with wires, you can build a safe electrical system that lasts longer!

Tips for Using Automotive Connectors Effectively

Proper Installation Techniques

Stripping wires correctly without damaging them

Stripping wires is an important first step. Use a good wire stripper to remove the cover carefully. Avoid cutting the wire strands, as this weakens the connection. Hold the wire steady, match the stripper to the correct size, and pull smoothly. Do not use knives or scissors; they can harm the wire.

Pro Tip: Check how much wire is exposed. Too much may cause short circuits, while too little won’t fit securely in the connector.

Crimping and soldering for secure connections

Crimping makes strong connections that handle vibrations well. Use a crimping tool made for your connector type for best results. Insert the wire into the connector, position it in the tool, and press firmly until tight.

Soldering can make joints that break easily under stress. Experts say crimping lasts longer than soldering. A good crimped joint is often stronger than the wire itself.

Quick Tip: After crimping, gently tug on the wire to ensure it’s attached properly.

Tools Required for Installation

Wire strippers, crimping tools, and heat shrink tubing

The right tools make installation easier and better. Wire strippers remove insulation cleanly without damage. Crimping tools secure wires tightly to connectors. Heat shrink tubing protects connections from water and dirt by sealing them tightly when heated.

Essential Tools Checklist:

Wire stripper

Crimping tool

Heat shrink tubing

Heat gun

Multimeters for testing connections

A multimeter checks if your connections work properly. It measures voltage, resistance, and continuity in wires. Set it to continuity mode after connecting wires and touch both ends with probes. A beep or zero reading means a solid connection was made.

Pro Tip: Test every connection right after installing it to avoid future problems.

Common Mistakes to Avoid

Over-tightening or under-tightening connections

Tighten connectors just enough so they hold securely but don’t bend metal parts. Over-tightening damages connectors; under-tightening makes loose connections that fail easily.

Using low-quality or incompatible connectors

Cheap connectors might save money but often break quickly. Always pick ones that match your car’s needs and wiring size exactly. Wrong connectors can overheat or stop working properly later on.

Avoid These Pitfalls:

Skipping compatibility checks

Choosing unreliable connectors

Tightening too much or too little

By using these tips, having proper tools, and avoiding mistakes, you’ll create safe electrical systems that last longer!

Benefits of Using High-Quality Connectors

Good connectors are important for your car's electrical system. They are strong, reliable, and easy to use. This makes them a smart choice for any wiring job.

Better Reliability

Lowering chances of electrical problems

Using good connectors helps avoid electrical issues. They keep wires connected well, even with heavy use. Unlike cheap ones, they stop problems like short circuits or loose connections that could hurt your car’s performance.

Fact: Good connectors have low resistance, which stops overheating and improves efficiency.

Working well in tough conditions

Cars often face heat, cold, or shaking while driving. High-quality connectors stay secure and work well in these situations. This ensures systems like headlights or brakes always work when needed.

Tip: For tough jobs, pick connectors with extra locks for safety.

Stronger Durability

Fighting rust and damage

Good connectors don’t rust or wear out easily from water or dirt. This keeps them working longer without needing fixes or replacements often.

Pro Tip: Pick ones made from strong materials like stainless steel for long-lasting use.

Lasting through harsh weather

Cars deal with bad weather and road salt often. Good connectors handle these without breaking down. This saves money by reducing repair costs over time.

Quick Insight: Cheap connectors can break quickly, causing expensive repairs later on.

Easier to Use

Simple to install and fix

High-quality connectors are easy to put together. Their design helps wires fit tightly and stay secure. Fixing them is also easier since they rarely loosen or rust over time.

Checklist for Easy Installation:

Choose marked connectors for correct wire placement.

Use designs with built-in strain relief features.

Useful for many projects

Good connectors work with different types of auto wires. Whether fixing simple parts or advanced systems like fast data transfer, they adjust easily to your needs.

Did You Know? HSD connectors are great for fast systems like Ethernet in cars.

By choosing high-quality connectors, you make your car’s electrical system safer and stronger. These save time and money while keeping everything running smoothly!

Maintenance Tips for Long-Term Performance

Taking care of automotive connectors helps them last longer and work better. Follow these tips to keep your car’s electrical system in good shape.

Regular Inspections

Look for loose or broken connections

Check your connectors often to spot loose or broken parts. Loose ones can stop electricity from flowing, causing problems with lights or brakes. Gently pull on each connector to see if it’s secure. If it moves too much, tighten it or replace it right away.

Tip: Inspect every few months or after bumpy rides to find problems early.

Spot signs of damage or rust

Look for damage like torn wires or cracked plastic covers. Rust, caused by water or road salt, looks greenish or white on metal parts. Rusty connectors weaken the connection and may cause failures. Fix these issues quickly to avoid bigger problems.

Pro Tip: Use a flashlight to check hidden spots for rust or wear.

Cleaning and Protecting Connectors

Clean off dirt with special sprays

Dirt builds up on connectors over time, making them less effective. Use a special contact cleaner spray to clean them without harm. Spray directly onto the connector and wipe with a soft cloth. This improves how well they work and stops future troubles.

Quick Tip: Don’t use water or regular cleaners; they might cause damage.

Add grease to block moisture

Dielectric grease protects against water and rust. After cleaning, put a small amount on the metal parts of the connector. It keeps rust away and helps maintain strong connections.

Did You Know? Dielectric grease is great for wet areas like rainy places or snowy roads.

Replacing Old Connectors

Know when it’s time to replace them

Some connectors get too damaged to work properly anymore. Cracks, heavy rust, or melted plastic mean you need new ones soon. Ignoring this can lead to bigger electrical issues later on.

Fact: Changing bad connectors early saves money on costly repairs later.

Pick replacements that match perfectly

Always choose new connectors that are just like the old ones in size and type. This ensures they fit your car’s system correctly without causing trouble. Check your car manual or ask an expert if unsure about what to buy.

Checklist for Replacement:

Match wire size.

Choose correct type (like blade, bullet, pin).

Ensure proper voltage and current ratings.

By checking, cleaning, and replacing connectors when needed, you’ll keep your car running smoothly. These easy steps make sure your electrical system stays reliable while improving overall performance!

Picking the right wire connectors and using them well is important. Good connectors lower the chance of electrical problems. They keep things like lights and brakes working safely. These connectors are easy to install and last a long time. This saves both time and money in the future. Follow the tips here to improve your car’s wiring projects. Doing this makes driving safer and more efficient. Start now by choosing strong connectors and good habits for worry-free driving!

See Also

Why FAKRA Connectors Matter in Automotive Systems

Significance of Fakra Connectors in Automotive Sector

Key Role of HSD Connectors in Car Manufacturing