Revolutionary Advances in Car Harness Connectors Technology

Auto harness connectors are important for today's vehicles. They help make safe connections between electrical parts. These connectors are needed for things like brakes and steering, improving safety and the overall performance of cars. With the rise of electric vehicles, there is an increasing demand for better wiring harnesses. Companies are now using greener materials to protect the planet.

The world’s car wiring harness market may grow from $156.83 billion in 2023 to $298.51 billion by 2032. This growth is driven by the increase in electric cars and advancements in safety systems.

Key Takeaways

Car harness connectors are important for safety and car performance.

Smaller, lighter connectors save space and help cars use less fuel.

Green materials in wiring reduce waste and help the environment.

New Trends in Car Harness Connectors

Smaller Designs for Saving Space

Modern cars have more features than before. These features need extra wiring, but space is tight. Making connectors and wires smaller is now a big trend. Tiny connectors save space but still work well. Lighter designs also make cars use less fuel or battery power. As cars get smarter, small wire harnesses will help save space and improve performance.

Green Materials in Car Wiring

Car makers are now using eco-friendly materials for wiring. They are replacing old PVC with greener options. These materials lower pollution during production and disposal. For example:

Environmental Benefit | Explanation |

|---|---|

Lower Carbon Emissions | Using green materials cuts down harmful gases from making and throwing away products. |

Better Material Choices | New materials are renewable and kinder to the planet. |

Recycling and Less Waste | Focus on reusing and proper disposal to protect the environment. |

Scientists are working on recyclable and plant-based materials. These keep wires strong but are better for nature. Energy-saving production also reduces waste. By using green materials, companies help make the planet cleaner.

Smart Tech in Wire Harnesses

Smart tech is changing how wire harnesses work. New harnesses now use sensors and IoT to do more. Cars can talk to each other and roads for safety. Self-driving cars use these harnesses to read data and act fast. This tech helps connect cars and make them safer. As tech grows, wire harnesses will help cars become smarter and better.

Technological Innovations in Automotive Wiring Harness

Fast Data Sharing with Plastic Optical Fiber

Fast data sharing is changing car wiring systems. Plastic optical fiber (POF) helps make this possible. It can send data up to 800 Mbit/s over 100 meters. This ensures quick and steady communication between car systems. Future updates may increase speeds to 3.2 Gbit/s. This will make car technology even better. POF connects many control units (ECUs) in cars. These ECUs are important for safety and entertainment features. For example, BMW’s 7 Series uses Byteflight tech to link 13 ECUs. This allows features like seat sensors and gear shifting. It improves how cars connect and perform.

Easy-to-Use Modular Connectors

Modular connectors make car wiring simpler. They reduce the mess of wires, making setup and repairs easier. These connectors also lower costs for new car designs by up to 20%. They can be customized for different car interiors. This makes them flexible and efficient. Using modular designs helps create better wiring systems. It saves time and keeps wiring ready for future upgrades. This approach meets the needs of today’s advanced cars.

Wireless Battery Systems for Electric Cars

Wireless battery systems (wBMS) are changing electric car wiring. They remove up to 90% of the wires, cutting weight and saving energy. Without wires, batteries can be placed more freely. This allows for bigger batteries and longer driving ranges. It also makes battery setup and repairs easier. wBMS improves energy use and reliability. This supports the growing need for better battery systems in electric cars.

Market Drivers and Challenges in the Automotive Wiring Harness Market

Growth of Electric Vehicles and Advanced Driver-Assistance Systems

Electric cars are changing the wiring harness market. They need more wires than regular cars. These wires link batteries, motors, and power units. High-voltage wires move power efficiently, which is vital for electric cars. In the U.S., more people are buying electric and hybrid cars. This has increased the need for strong wiring systems. By 2033, the global market for electric car wiring systems may reach $94.96 billion.

Driver-assistance systems also need advanced wiring. These systems connect cameras, sensors, and control units. Smarter cars require better wiring to improve safety and performance. Luxury cars especially need high-tech wiring for entertainment and connectivity features.

Sustainability and Regulatory Pressures

Sustainability is now a big focus in car wiring. Companies are using recycled plastics and biodegradable materials. These options are better for the planet and still work well. Governments are pushing for greener designs that save energy and reduce weight. These changes match the goals of making cleaner cars and cutting emissions.

Rules also affect the market. Companies must follow strict standards for electric car wiring and driver-assistance systems. This has led to more research into eco-friendly materials and energy-saving production methods.

Supply Chain and Manufacturing Constraints

The wiring harness industry faces some problems. Driver-assistance systems and sensors make wiring designs harder. Manual production methods can’t keep up with these changes. Material shortages also slow down production.

Challenge Type | Description |

|---|---|

Complex Technology | Driver-assistance systems and sensors make wiring harder to design. |

Lack of Automation | Manual methods can’t handle the growing complexity of wiring. |

Material Shortages | Missing materials make it hard to produce enough wiring. |

To fix these issues, companies are using automation and new materials. These steps help speed up production and meet the demand for better wiring systems.

Real-World Uses of Car Harness Connectors

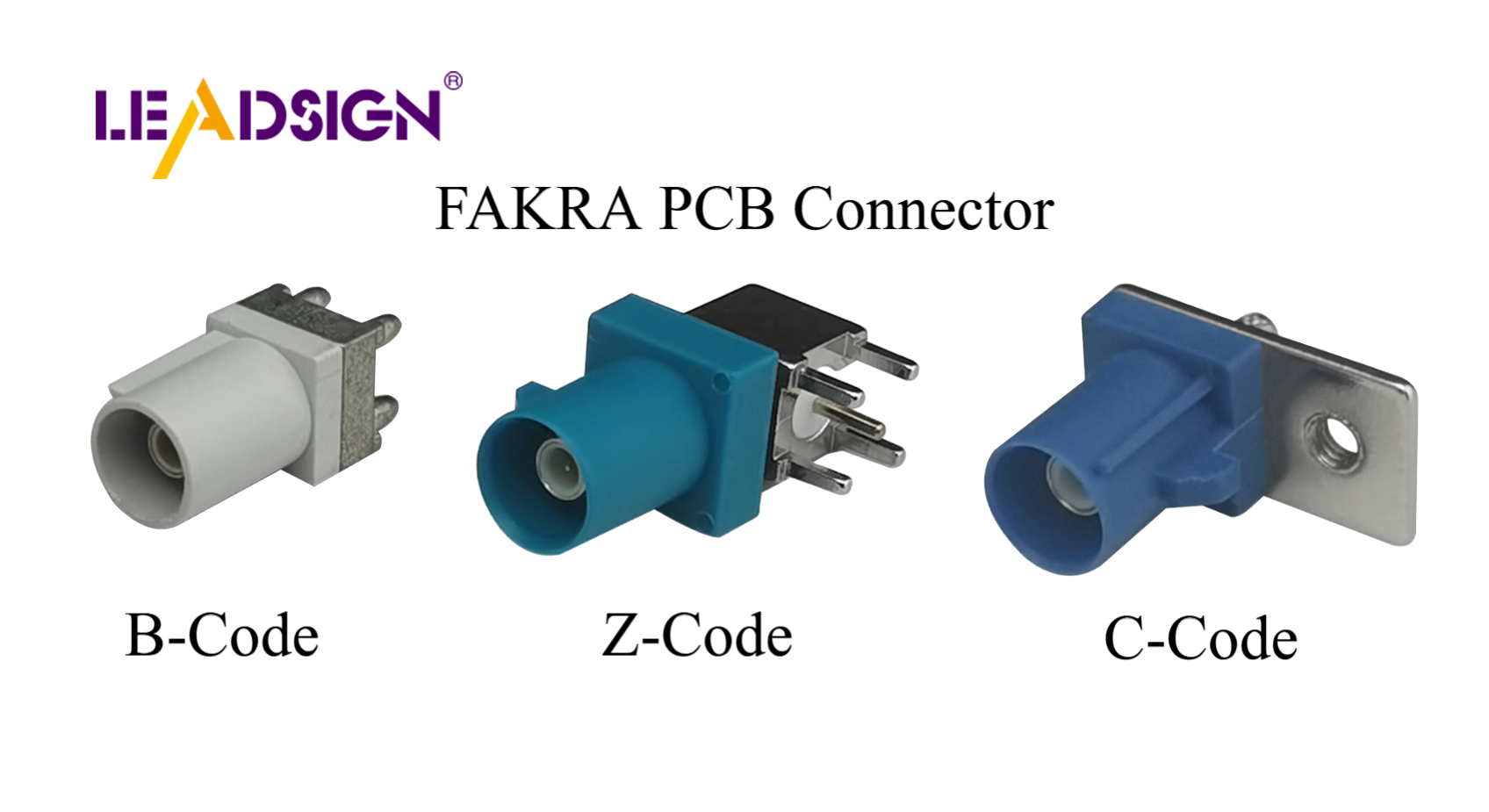

FAKRA Connectors in Car Electronics

FAKRA connectors are important in today’s car electronics. They are used in systems like GPS, Bluetooth, and satellite radio. These connectors send clear signals for reliable communication. Built for tough conditions, they resist water, interference, and stress. This makes them great for electric cars and self-driving technologies.

FAKRA connectors also work with high-voltage systems. They provide stable links for infotainment and telematics. Their design prevents misuse and saves space. From connecting antennas to enabling Bluetooth, they keep car electronics working well.

Smart Connectors in Self-Driving Cars

Smart connectors are key for self-driving car systems. They quickly share data between LIDAR, RADAR, and the internet. These connectors help cars stay connected to their surroundings. This is vital for safe and efficient driving.

Smart connectors handle extreme heat and vibrations. They link sensors, cameras, and controls into one network. Without them, self-driving cars couldn’t navigate or detect obstacles.

Uses in EV Batteries and Infotainment

Car harness connectors are crucial for electric vehicles. They connect battery parts for steady high-voltage power. These connectors also link sensors to improve battery performance. They help batteries last longer and use energy better.

In infotainment systems, connectors link screens, speakers, and controls. This makes driving more fun with smooth entertainment and communication. Whether powering EVs or running infotainment, these connectors are essential for modern cars.

Future of Automotive Wiring Harness Technology

What’s Next for Wire Harness Assemblies

The future of wire harnesses looks exciting with new technology. Wiring systems will become better and more dependable. Companies are using robots and AI to make production faster. This helps meet the rising need for wiring in cars and gadgets.

Being eco-friendly is also a big focus. Businesses are choosing greener materials to cut pollution. Electric cars need advanced harnesses for high-voltage power and smart designs. These changes will make cars lighter and save energy, helping the planet.

How AI and Machine Learning Help Connectors

AI and machine learning are changing how connectors are made. These tools study lots of data to design smarter wiring. AI can find problems early, making fewer mistakes in production. Machine learning improves designs to last longer and work better.

In future cars, AI connectors will link systems smoothly. This will boost safety, communication, and automation. By using AI, companies can create new ideas and stay competitive in the market.

Changes in the Automotive Wiring Harness Market

Better wiring technology will change the car industry. As electric and self-driving cars grow, smarter wiring will be needed. High-voltage harnesses will save energy, and smart tech will improve connections.

New rules for safer and greener cars will push innovation. This will make vehicles better for people and the environment. Growing markets will bring more chances for success, making the future bright for this industry.

The progress in car harness connectors is changing the car world.

Improvement Type | Details |

|---|---|

Lighter Materials | Using materials like aluminum cuts car weight by 40%. This makes cars more efficient. |

Advanced Driver-Help Systems (ADAS) | ADAS needs strong wires to connect sensors and controls. |

Smart and Self-Driving Cars (CAVs) | These cars need many wires to talk to other cars and systems. |

These changes boost safety, save energy, and improve connections. Electric cars and ADAS need better wiring to work well. Car makers use new materials and methods to solve these problems. Better wiring tech keeps cars safe, efficient, and ready for the future.

FAQ

What is an automotive wiring harness?

An automotive wiring harness links electrical parts in a car. It helps systems like lights, sensors, and radios work together smoothly.

Why is the automotive wiring harness market growing?

The market is growing because of electric cars and smart systems. These need better and more advanced wiring to function well.

How do eco-friendly materials impact the automotive wiring harness market?

Eco-friendly materials are better for the environment. They support green goals and are important for making modern car wiring.

See Also

Transforming Vehicle Connectivity With HFM Connector Benefits

Exploring Mini FAKRA Connectors Benefits For Today's Cars

Discovering Mini Fakra Connectors Benefits In Auto Systems