The Future of Custom Automotive Wiring Harness Solutions

You depend on auto harness connectors to power systems in your vehicle. They connect important parts to work together seamlessly. These harnesses help systems like entertainment and safety communicate effectively. As cars improve, custom harnesses become increasingly important. New technology and connectors bring innovative ideas for the future of car wiring.

Key Takeaways

Custom car wiring harnesses link systems, boost performance, and add safety.

Lightweight, strong materials in harnesses save fuel and improve cars.

Using recyclable materials helps the environment and keeps companies competitive.

Challenges in Automotive Wiring Harness Design

Creating a car wiring harness isn’t easy. As cars get smarter, it’s harder to balance performance, efficiency, and being eco-friendly. Let’s look at some big challenges in this area.

Material Shortages and Supply Chain Problems

Making wiring harnesses is tough when materials run low. Copper, which is very important, often has supply issues. These problems can slow down production and raise costs. Finding other materials without losing quality is tricky. To stay ahead, companies must plan well and work with trusted suppliers.

Weight and Space Issues in New Cars

New cars need smaller and lighter designs. Engineers must fit more parts into tight spaces while keeping weight down. Heavy wiring can hurt fuel use and performance. To fix this, engineers use lighter materials and smart designs. This helps the harness fit better into the car.

Being Eco-Friendly and Following Rules

Car wiring companies now focus on being green. Governments have strict rules to protect the environment. Companies must use eco-friendly materials and methods to follow these rules. Recycling and reusing materials help meet these goals. Using green tech keeps companies competitive and helps the planet.

Automotive Wiring Harness Trends for 2025

Lightweight and Strong Materials for Better Performance

Modern cars need lighter parts to save fuel and work better. Wiring harness makers now use materials like aluminum and strong plastics. These materials are light but still tough. This change helps both electric and regular cars become more efficient.

Easy-to-Adjust Wiring Systems

New wiring systems make car designs more flexible. You can add or remove parts without much trouble. This works well for different car models. It also saves time and money since the whole harness doesn’t need redesigning.

Fiber Optics for Faster Data Sharing

Fiber optics are changing how car wiring works. They send data quickly, which is important for cameras, screens, and self-driving features. Fiber optics are smaller than regular wires, so they fit better in tight spaces.

Better Shields to Block Interference

Electromagnetic interference (EMI) can mess up car electronics. To fix this, companies use special shields to protect parts. These shields keep systems working smoothly, especially as cars get more connected.

Smart Wiring with Sensors and Internet Features

Smart harnesses are the next big thing in car wiring. They have sensors that check how things are working and spot problems fast. With internet features, you can get updates and fixes on your devices. This makes driving safer and easier to manage.

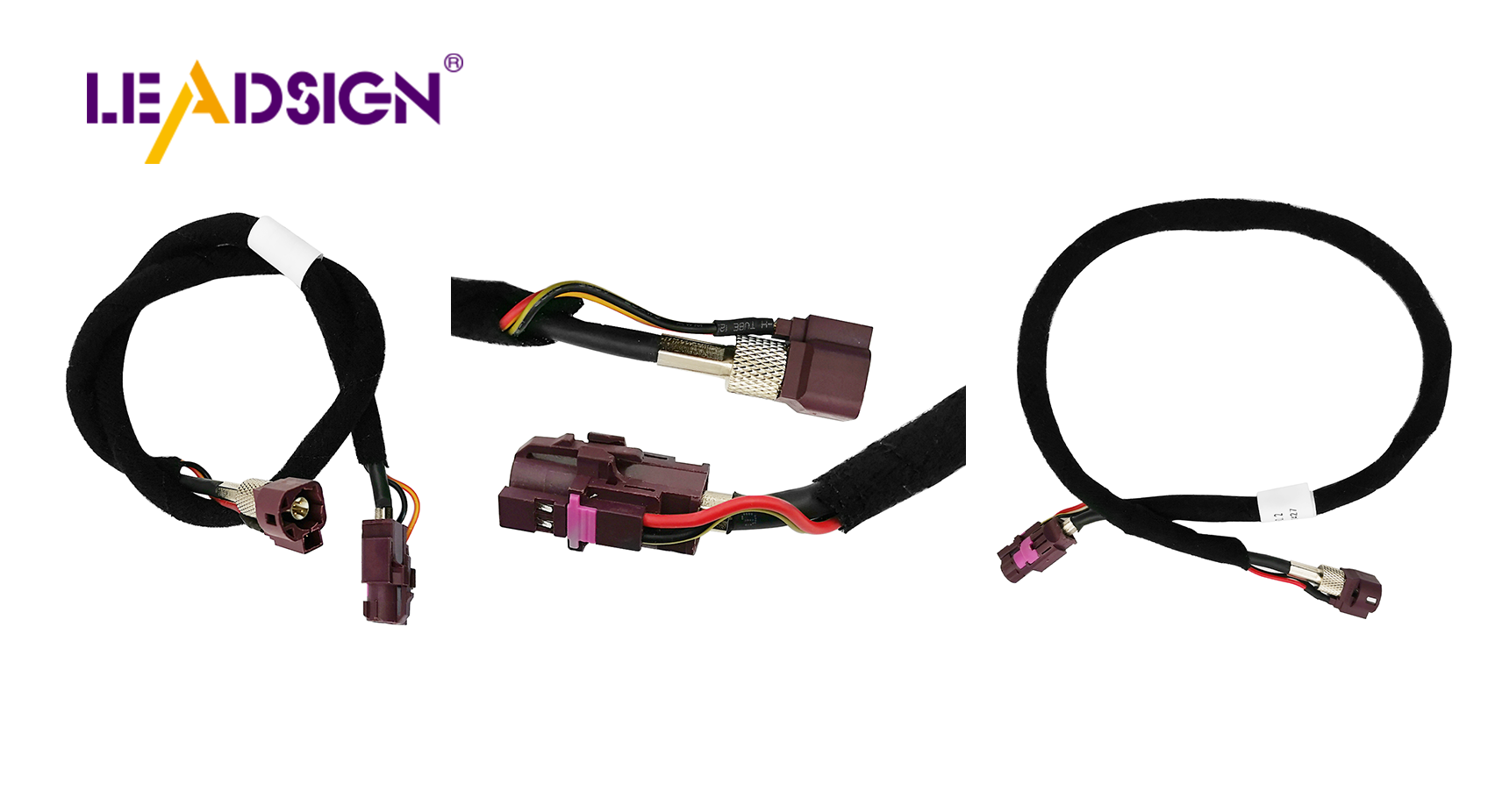

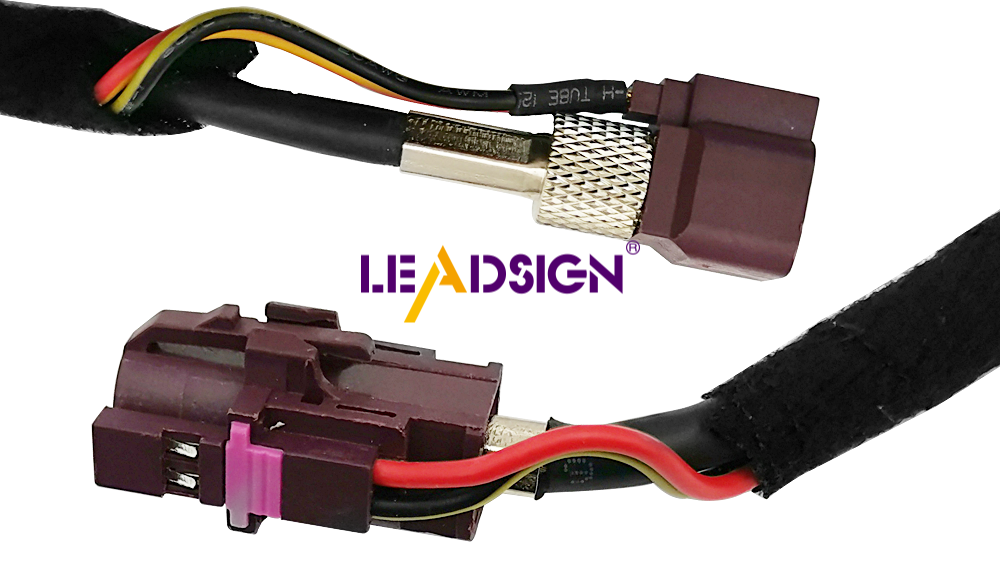

The Role of Custom Auto Harness Connectors

Meeting Needs of Electric and Self-Driving Cars

Electric and self-driving cars need better wiring solutions. Harness connectors must handle fast data and strong power flows. These cars use many systems like cameras, sensors, and controls. Special connectors, such as push-to-seat and pull-to-seat types, help these systems work well. They also lower mistakes during setup. As the wiring market grows, makers focus on connectors for these cars. These new ideas help create smarter and greener vehicles.

Making Production Easier and Less Complicated

Custom connectors make building cars simpler. They cut down on setup time and mistakes. Push-to-seat and pull-to-seat connectors are good examples of this. They make installing wires quicker and more dependable. Modular designs also help by letting you swap parts easily. You can upgrade or fix parts without redoing everything. This saves time and money, making production smoother.

Fitting Different Car Models Easily

Wiring harnesses must work with many car types. Custom connectors make this possible. For example, a universal connector can fit different car designs. This helps manufacturers build for various models, like electric and hybrid cars. Flexible designs allow companies to meet these needs. This keeps production fast and supports the growing wiring market.

Boosting Safety and Dependability in Wiring Systems

Safety is very important in car wiring. Custom connectors make systems more reliable by ensuring strong connections. Using good materials and smart designs lowers the chance of problems. Advanced tech also improves performance. For instance, locking connectors stop wires from coming loose by accident. These features make sure your car’s systems are safe and work well.

New Ideas in Car Wiring Harness Solutions

Tesla's Smarter Wiring with Regional Computers

Tesla changed car wiring by using smaller computers in the car. These computers are placed in different areas instead of one big one. This setup uses less wiring, making it lighter and better. Systems talk to each other faster, and the car works smoother. Tesla’s design also costs less to make, helping the wiring market grow. This new way of wiring sets a high standard for others to follow.

Rivian's Special Wiring for Electric Cars

Rivian makes electric cars with special wiring harnesses. Their designs are easy to fix or upgrade because they are modular. These harnesses are also strong enough for the high power EVs need. Rivian’s ideas help meet the demand for greener and smarter wiring. Their work shows how tech can fit the needs of modern electric cars.

Fast Data Connectors for Better Car Features

Fast data connectors are changing how cars share information. These connectors, like HSD systems, send data quickly and reliably. They improve things like cameras, maps, and entertainment systems. They also help self-driving cars by connecting sensors and processors smoothly. As wiring tech grows, these connectors are key to better car technology.

Teamwork Between Companies for Better Wiring

Car makers and tech companies work together to improve wiring. These partnerships bring new ideas by mixing skills from both sides. For example, they create harnesses with fiber optics and smart tech. This teamwork speeds up the use of advanced materials and designs. By working together, they keep car wiring ahead of the curve.

Future Outlook for Automotive Wiring Harnesses

Using Recyclable Materials for a Greener Future

Choosing eco-friendly materials helps make car wiring better for the planet. Companies now use recyclable items like bio-plastics and light metals. These materials cut down on waste and save resources. Recycling old wires also reduces harm to the environment. Supporting green designs helps create a cleaner car industry. Being eco-friendly is now a must to stay competitive.

Smarter Designs with AI and Machine Learning

AI and machine learning are changing how car wiring is made. These tools study lots of data to find the best designs. For example, AI can plan wire layouts to save weight and energy. Machine learning spots problems before wires are built. This saves time and makes better-quality harnesses. With these tools, smarter and more advanced wiring is possible.

Custom Wiring for Modern Cars

Custom wiring is important as cars get more advanced. Wires need to match systems like cameras and sensors perfectly. Custom designs make setup and repairs easier and faster. They also work well with electric and self-driving cars. As technology grows, the need for special wiring will increase. Custom solutions help you keep up with the fast-changing car world.

You help shape how car wiring harnesses improve in the future. Solving problems with smart and custom ideas helps cars meet today’s needs. Being eco-friendly, flexible, and using new technology pushes progress forward. Choosing custom wiring keeps you prepared and ahead in the changing car industry.

FAQ

What does a custom car wiring harness do?

A custom car wiring harness links parts in a vehicle. It helps them work together smoothly and meets specific needs for design and performance.

How does new tech make wiring harnesses better?

New tech makes harnesses lighter, faster, and smarter. These changes boost how well they work, last longer, and adjust to new needs.

Why use recyclable materials in wiring harnesses?

Recyclable materials cut down on waste and save resources. They help car makers follow eco-friendly rules and build greener solutions.

See Also

Maximizing Automotive Data Flow With Innovative Connectors

Boosting Data Transfer: Significance of Fast Automotive Connectors

Benefits of HFM Connectors for Automotive Applications

Harnessing High-Speed FAKRA-Mini Connectors for Automotive Use

Transforming Automotive Connections: Benefits of HFM Connectors