The Ultimate Guide to Custom Automotive Wiring Harness Selection

Choosing the right auto harness connectors is very important. Good connectors keep your car safe and working well. They stop problems like system failures or fires by managing electricity properly. Special connectors made for tough conditions last longer. These are key for cars and custom wiring systems.

Key Takeaways

Pick good connectors to keep your car's wiring safe.

Think about heat and water when choosing connectors to avoid problems.

Check and care for connectors often to make them last longer.

Understanding Automotive Wire Harness Connectors

What Are Wire Harness Connectors?

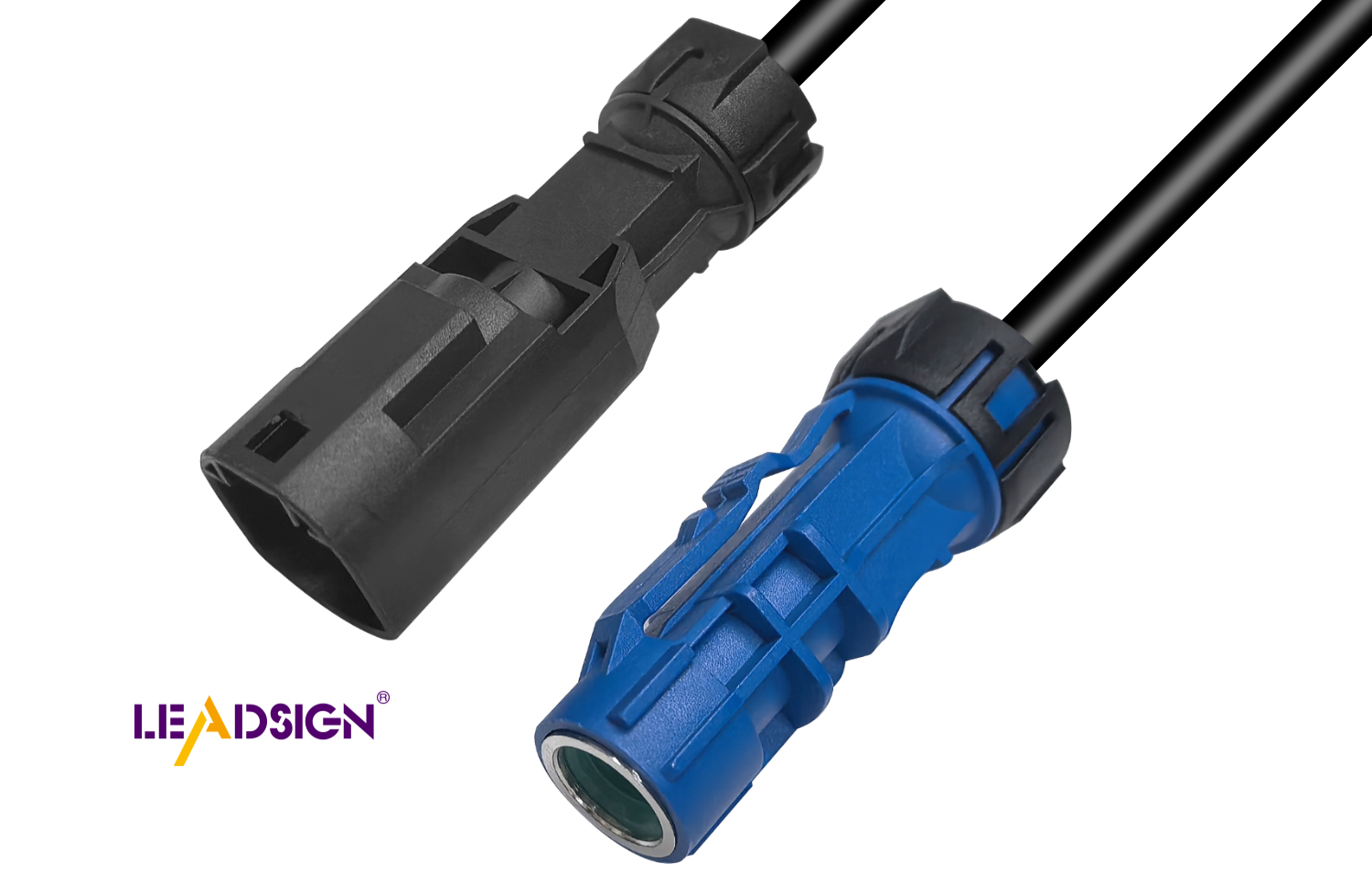

Wire harness connectors are important parts of a car's electrical system. They connect wires to devices, helping power and data move smoothly. These connectors come in many shapes, sizes, and designs for different uses. For instance, some are for inside systems like radios, while others link outside tools for repairs or checks.

The main jobs of wire harness connectors are shown below:

Function | Description |

|---|---|

Internal connectivity | Links parts inside the car, like radios and sensors. |

External connectivity | Connects the car to tools for fixing or checking. |

Replacement | Lets you swap devices temporarily to keep the car running. |

Knowing these uses shows how connectors help your car's electrical system work well.

Role of Auto Electrical Connectors in Vehicle Systems

Car electrical connectors are key to the car's power system. They join wires to parts, letting electricity and data flow through the car. Without them, systems like lights, engines, and radios wouldn’t work.

Here’s how these connectors help your car:

They move power and data so systems run smoothly.

They are built for modern cars, lasting longer and working better.

Picking the right connectors keeps your car safe and reliable.

Good-quality connectors make your car safer overall. Bad connectors can cause problems or even accidents. Choosing strong, well-made connectors lowers risks and boosts your car’s performance.

Types of Auto Harness Connectors

Knowing the types of car wire connectors is important. It helps you pick the right one for your car. These connectors are grouped by how they connect, their electrical use, and the environment they face.

By Connection System

Car wire connectors are sorted by connection types like wire-to-wire, board-to-wire, and device links. Each type has a specific job:

Connection Type | Description |

|---|---|

Wire-to-wire | Has male and female parts, used in small systems or main harness links. |

Board-to-wire | Attached to a board, connects the engine control unit to power. |

Device Connections | Used in sensors, includes pre-made female parts for specific uses. |

Wire-to-wire connectors are for smaller setups. Board-to-wire ones link control units to power. Device connectors are key for sensor systems, helping data move smoothly.

By Electrical System

Car wire connectors for electrical systems depend on certain needs. These include current, voltage, wire size, and weather. Keep these tips in mind:

Pick a connector that handles the needed power to avoid overheating.

Match the wire size with the connector for better results.

Use connectors that resist heat, water, and rust.

Also, materials and signal quality matter. Low resistance keeps signals strong. Strong materials like metal or plastic make connectors last longer.

By Environmental Factors

The environment affects which wire connectors you should use. Think about these things:

Extreme hot or cold temperatures

Wet or humid conditions

Fluids like brake oil or antifreeze

Dirt or harmful chemicals

IP (Ingress Protection) ratings

Sealed connectors work well in wet places. Tough materials like nylon or PBT protect against fluids and dirt. Checking these factors helps your wiring stay reliable in tough conditions.

Key Points for Picking Automotive Wire Harness Connectors

Electrical Needs

When choosing wire harness connectors, check the electrical needs. These include power, voltage, and signal quality. Wrong choices can cause overheating or bad performance. Use this table to learn key points:

Requirement | Description |

|---|---|

Check for heat, moisture, and dirt exposure. Pick connectors with good IP ratings for lasting use. | |

Mechanical Factors | Choose connectors that handle shaking and movement. Locking parts and strain relief help keep connections strong. |

Type of Termination | Look at how wires connect (soldering, crimping, or screw-on). This affects signal quality and how easy it is to assemble. |

Material | Pick plastic (light and strong) or metal (for tough jobs) based on your needs. |

Signal Integrity | Use high-quality materials to keep signals strong and avoid loss, especially for fast data systems. |

Interchangeability | Find connectors that work with different brands. This avoids supply problems and adds advanced features. |

Environmental Conditions

The environment affects how well connectors work. Heat, water, and dirt can make them fail. Pick connectors made for tough conditions. Sealed connectors with high IP ratings are great for wet areas. Materials like nylon or PTFE resist heat and chemicals, making them last longer in harsh places.

Material Strength and Durability

Connector materials affect how long they last and work. Strong materials like PTFE, nylon, and polyurethane resist heat, chemicals, and wear. Copper is flexible and conducts electricity well, while aluminum is light and cheaper. Shielding, like foil or braided covers, keeps signals clear and blocks interference. Always pick materials that fit your car's wiring needs.

Matching Vehicle Needs

Connectors must fit your car’s wiring system perfectly. Think about heat, stress, and how wires connect. Make sure the connector fits your car’s design and keeps signals strong. Connectors that work with many brands make repairs and sourcing easier.

Benefits of High-Quality Auto Electrical Connectors

Better Performance and Dependability

Good-quality car connectors help your vehicle work properly. They make sure electricity flows smoothly, powering lights, radios, and engines. Using strong connectors lowers the chance of system problems or failures.

These connectors are built with secure locks and tough designs. This stops them from coming loose, even in bumpy rides. High coding efficiency prevents wrong connections, making everything work perfectly. Reliable connectors improve how well your car performs overall.

Longer Life for Wiring Systems

Strong connectors make your car's wiring last longer. Weak connectors can get dirty or rusty, stopping electricity from flowing. This can break your systems early. Good connectors keep electricity steady, helping systems last longer.

Premium connectors also have strain relief to stop wires from pulling loose. Weatherproof ones, made from nylon or PTFE, handle tough conditions. They resist chemicals, water, and heat, keeping your wiring safe for years.

Lower Chance of Electrical Problems

Cheap connectors often cause overheating, broken insulation, or loose wires. You can avoid these by picking connectors made for your car.

To stop problems, follow these tips:

Pick connectors that last through many uses without wearing out.

Use connectors with good IP ratings to block water and dust.

Make sure they handle the heat levels in your car.

Choose connectors with strong locks to avoid loose connections.

Using high-quality connectors cuts down on failures. This keeps your car safe and working well, even in tough conditions.

Installation and Maintenance of Wiring Harness Connectors

Best Practices for Installation

Installing wiring harness connectors the right way is important. Follow these steps to make sure they work well:

Prepare the wires: Remove the wire cover carefully. Expose just enough wire without cutting the strands.

Insert the wires: Place the wires into the connector slots. Make sure they line up correctly.

Secure the connector: Lock the wires tightly in place. This stops them from coming loose when the car shakes.

Test the connection: Check if electricity flows properly. Make sure the connector works as it should.

Tip: Check if the connector case protects against water, dirt, and chemicals. Use connectors with strong locks to avoid accidental disconnections. Always ensure they meet car standards like ISO or SAE.

Regular Maintenance and Inspection

Taking care of connectors keeps them working longer. Here’s why it matters:

Rust can harm connectors, especially in tough conditions. Look at them often to spot damage early.

Cover connectors with tape or grease to keep out water. This helps them last longer.

Regular checks find loose wires or broken parts before they cause big problems.

Note: Checking connectors often makes them last longer. It also keeps your car running safely and smoothly.

Troubleshooting Common Issues

Fixing problems quickly keeps connectors working well. Here are common issues and how to solve them:

Wiring harness design mistakes: Wrong wire sizes can overheat. Use design tools to get the right fit.

Manufacturing defects: Bad machine settings can cause weak connections. Work with experts and use quality checks.

Unprotected contacts: Rust from exposure can block power. Add coatings to stop this.

Poor crimping techniques: Bad crimping lets water in, causing short circuits. Use the right tools for tight crimps.

No strain relief: Movement can break connectors without support. Add strain relief to protect them.

Pro Tip: Fixing these problems quickly keeps your wiring harness connectors strong and dependable.

Picking the right automotive wire harness connectors is very important. They help keep your car safe and working well. Think about these points when choosing:

Environmental Conditions: Pick connectors with good IP ratings. They should handle heat, water, and dirt.

Mechanical Factors: Use connectors with locks and strain relief. These help them stay secure during movement.

Material: Choose plastic for light use or metal for tough jobs.

Signal Integrity: Make sure they have low resistance for smooth data flow.

Interchangeability: Find connectors that work with many brands. This makes repairs easier.

Check out trusted brands like Molex, TE Connectivity, and Delphi Automotive. Here’s a simple comparison:

Brand | Features |

|---|---|

Molex | Strong and reliable, used by many professionals. |

TE Connectivity | Built for tough conditions, easy to use, and comes in many sizes. |

Delphi Automotive | Protected from rust, handles shaking, and works in extreme heat or cold. |

Learn what your car needs before buying. Read reviews to see how connectors work in real life. Picking the right ones will make your car run better and last longer.

FAQ

How can you stop water from damaging connectors?

Choose sealed connectors with good IP ratings. Use covers or coatings to keep water out and make them last longer.

How many times a year should you check connectors?

Check them twice a year. Look for rust, broken wires, or other issues to keep your car's electrical system working well.

Is it okay to use old connectors when changing a wiring harness?

Do not reuse old connectors. They might be worn out or damaged, which can cause problems. Always pick new, strong connectors for replacements.

See Also

Understanding Ford Fakra Connectors: A Comprehensive Overview

Introduction to HSD Connectors Within Automotive Applications

Enhancing Data Transmission in Vehicles: Connectors and Cables