Assessing Custom Wiring Harnesses in Today's Market

A custom wiring harness links electrical parts in a special way. It is important for cars, planes, and gadgets. The world wire harness market will grow from USD 40.44 billion in 2021 to USD 58.4 billion by 2030. This shows a growth rate of 4.25%. Custom wiring harnesses can change size and shape easily. They meet new needs well. These harnesses save money and work well for now and later. The car wiring market was USD 37.03 billion in 2022 and might be USD 47.46 billion by 2028.

Understanding Custom Wiring Harnesses

Basic Concepts

What is a wiring harness?

A wiring harness is a group of wires and connectors. It helps send electricity in cars or machines. Each wire has its own job. They connect parts to make things work smoothly. A custom harness is made for special needs. This makes it fit better and work well.

Components of a custom wiring harness

A custom harness has important parts. Wires are the main part, carrying electricity around. Connectors link wires to devices or other wires. Terminals hold wires in place inside connectors. Covers protect wires from damage outside. Each part helps the harness work right. Custom ones are made for certain jobs, reducing problems and making them reliable.

Advantages Over Standard Wiring

Customization benefits

Custom wiring harnesses have big advantages over regular ones. Special designs make them fit and work best. This cuts down on wasted materials and costs less to make. They help put electrical systems together easily. Precision wiring makes them more reliable and safe from harm outside.

Efficiency and performance improvements

Custom harnesses boost efficiency and performance by smart wire placement, lowering resistance, improving system function, allowing easy changes later, adding safety features, giving better results than normal options.

Market Analysis

Current Trends

Demand in Automotive Industry

The car industry needs special wiring harnesses. Electric cars need good wires to link systems. Custom harnesses help with unique designs and jobs. Makers focus on harnesses that boost car performance. This demand pushes new ideas and market growth.

Innovations in Materials and Technology

New materials and tech change custom wiring harnesses. New stuff makes them last longer and bend better. Better tech helps connect things and cuts weight. Engineers add smart features for new uses. These changes make sure they work well in many fields.

Key Players and Competition

Major Manufacturers

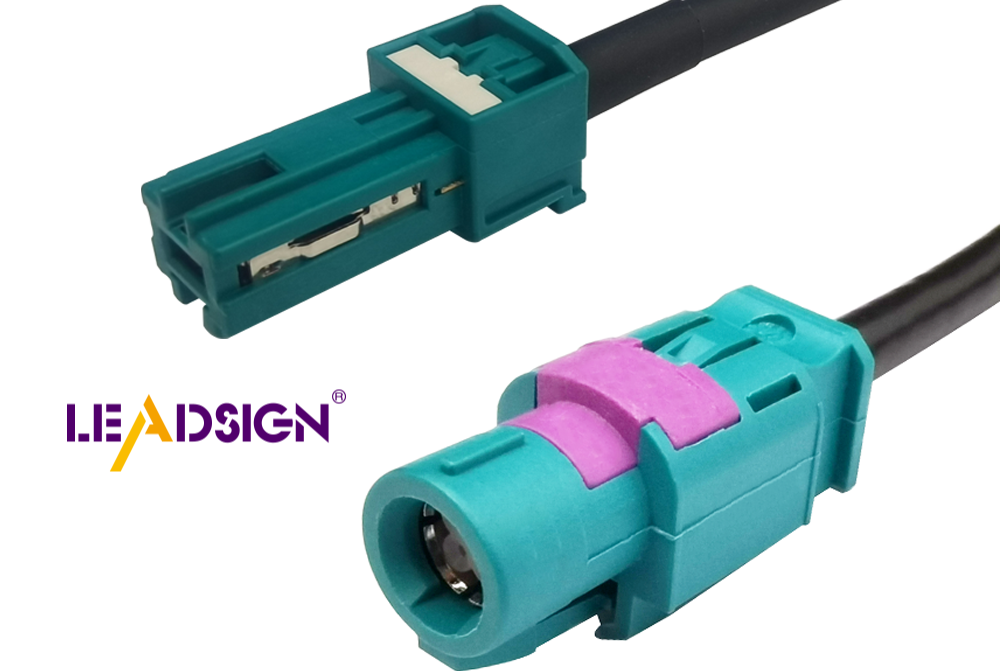

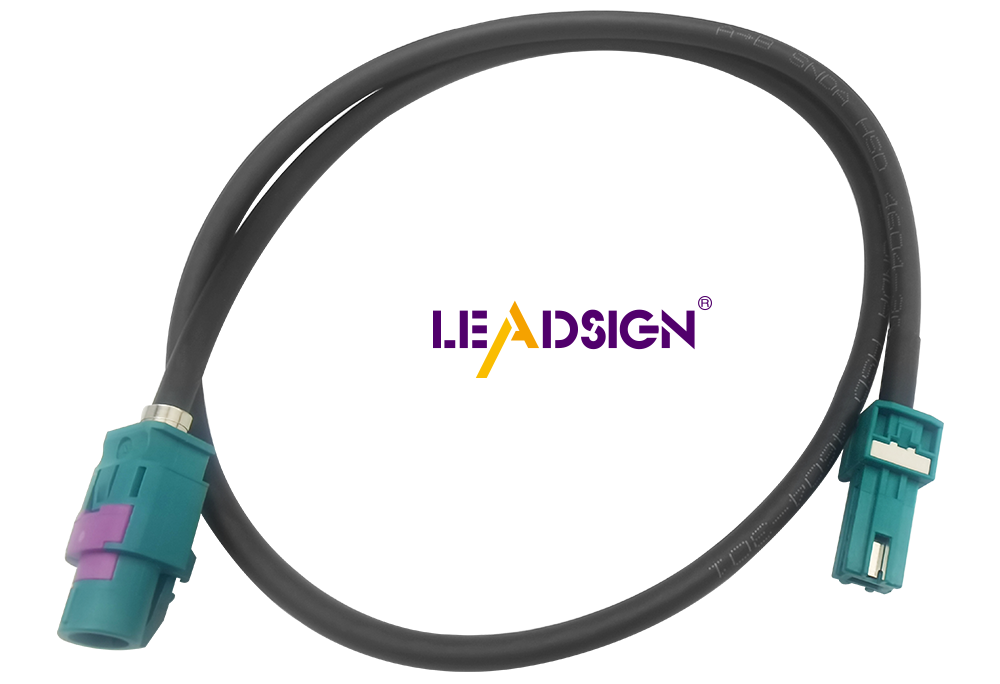

Big companies lead the custom wiring market. Firms like LEADSIGN make cool products for many areas. They focus on quality and making things special. Working with big car brands helps them grow strong. Their promise to be great makes them stand out.

Competitive Landscape

The wiring market is full of competition. Companies offer special solutions to win customers. New ideas and happy clients bring success. Businesses spend money on research to stay ahead. This competition helps the industry grow better.

Real-World Uses

Specific Industry Needs

Car Uses

Custom wiring harnesses are important for cars. Electric cars need these to link systems well. They help cars work safely and better. Custom harnesses solve tricky electric setups in new cars. Makers use them to make cars work great and last long.

Planes and Defense

Planes and defense need things to be exact and safe. Custom wiring harnesses do this by giving special solutions. They handle tough conditions and help parts talk to each other smoothly. Engineers make them fit planes and defense tools just right. This makes things run better and safer.

Examples of Success

Winning Stories

Example: Car Change

Goal: Make electric cars work better.

Fix: Use custom harnesses for good power flow.

Result: Cars go farther with less energy waste.

Example: Plane Trust

Goal: Keep plane systems talking well.

Fix: Use custom harnesses for key parts.

Result: Systems work better, need less fixing.

Lessons Learned

*Custom wiring harnesses save money over time*. They last longer, so fewer swaps are needed often. Being reliable cuts down on running costs later on. Industries gain from solutions made just for them, meeting needs well. Custom fits lead to safer, better working systems.

FAQs and Key Takeaways

Common Questions

How to pick the right custom wiring harness?

To pick a good harness, know what you need. Find out which parts need connecting. Think about where it will be used. Check how strong and bendy it should be. Talk to makers to match your needs.

Cost thoughts

Think about both starting costs and future savings. Custom harnesses waste less material. Smart designs can cut making costs. Look at how they might save on repairs later. Focus on total value, not just first price.

Summary of Insights

Important points to remember

Custom wiring harnesses are very helpful. They give special solutions for many jobs. These harnesses make things work better and save materials. They are safer with careful designs.

Future outlook

The future looks bright for custom harnesses. More people want them for cars and planes. New materials and tech help them improve. Custom ones will stay key for tricky systems. The market will likely grow more.

Custom wiring harnesses are important in today's industries. They help parts work together well, lowering problems. The market for these harnesses is still growing. New materials and tech make them better. Future changes will improve how they work and save energy. Look into new ways to use custom wiring. Keep creating new ideas to meet changing needs. Custom harnesses will be needed for tricky systems. Use the latest wiring technology to lead in the market.

See Also

Maximizing Automotive Efficiency with HSD Connectors

Essential Guide to HSD Connectors for Autos

Exploring High-Speed FAKRA-Mini Connectors for Autos