How to Assemble Pigtail Wires for Vehicle Cable Applications

Pigtail wire connections are important in vehicle cable systems. They help connect many wires safely for electricity to flow well. In cars, strong connections are needed for safety and good performance. A pigtail connector makes it easy to join wires neatly. It saves space and lowers the chance of shocks or fires. Using pigtails makes wiring safer, stronger, and easier to fix in vehicles.

Key Takeaways

Pigtail connectors enhance safety by preventing loose or uncovered wires, reducing the risk of sparks and short circuits in vehicle wiring.

Using the right tools, such as wire cutters, strippers, and crimping tools, is essential for creating strong and reliable pigtail connections.

Always test your connections with a multimeter after assembly to ensure they are functioning properly and to avoid future electrical issues.

Proper insulation with heat shrink tubing or electrical tape protects connections from dirt and moisture, extending their lifespan.

Pigtail connectors simplify repairs and replacements, allowing for quick fixes without disrupting the entire wiring system.

Choosing high-quality materials for pigtail connections leads to stronger, more durable wiring that can withstand the rigors of vehicle use.

Following safety precautions, such as turning off power and wearing insulated gloves, is crucial to prevent accidents while working with electrical wires.

Tools and Materials for Making Electrical Pigtails

To make strong pigtail connections, you need the right tools. Using proper tools keeps your work safe and long-lasting. Below is a simple guide to gather what you need.

Important Tools

You need specific tools to connect pigtail wires well. These tools make the job easier and safer.

Wire cutters and strippers

Wire cutters trim wires to the right length. Strippers remove the plastic cover without harming the wire inside. Good tools give clean and neat results.Crimping tool

A crimping tool tightly connects wires to connectors. It presses them together so they stay secure.Heat gun or lighter (for heat shrink tubing)

Heat shrink tubing covers and protects the connection. A heat gun or lighter shrinks the tubing to fit tightly. This keeps dirt and water out.Multimeter (for testing connections)

A multimeter checks if electricity flows through the wires. It helps confirm that the connection works properly.

Needed Materials

The materials you pick are just as important as the tools. Choosing the right ones makes the connection strong and reliable.

Electrical wires

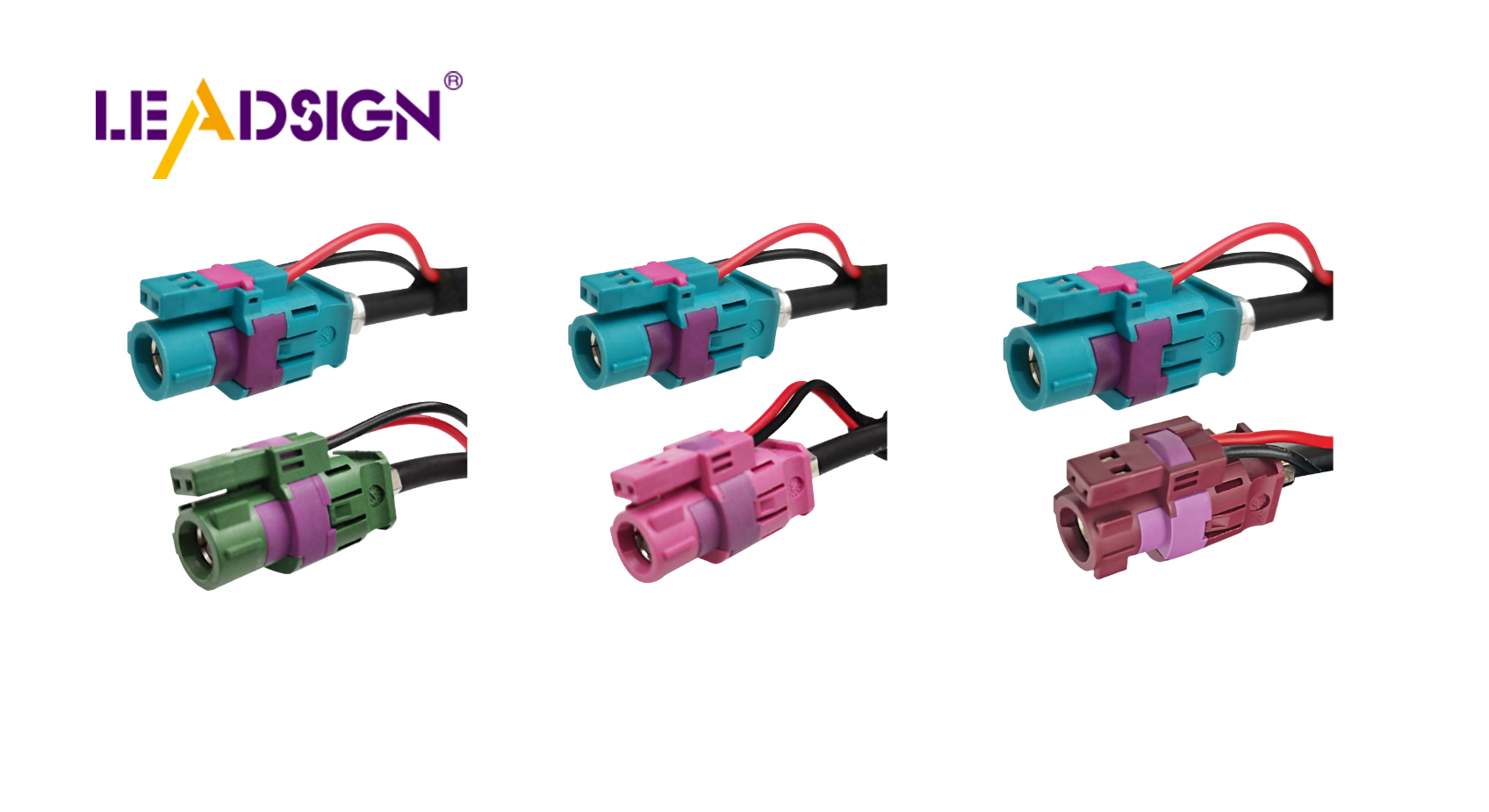

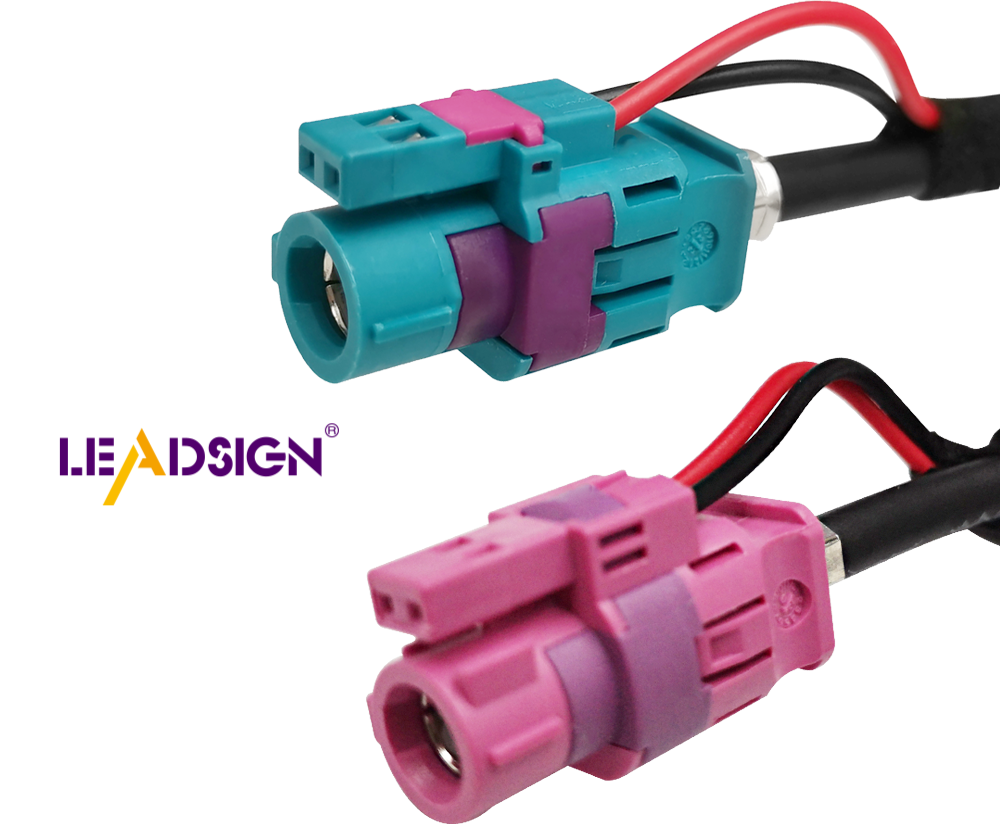

Use wires that match your circuit's needs. White wires are neutral, red or black are live, and green or bare copper are for grounding. Cut wires to six to eight inches for easy use.Pigtail connectors (e.g., wire nuts, crimp sleeves)

Pigtail connectors join wires securely and keep things tidy. Pick connectors that fit your wire size to avoid loose connections.Heat shrink tubing or electrical tape

Heat shrink tubing gives a clean look and strong insulation. Electrical tape can also insulate but isn’t as durable.Solder (optional for added strength)

Soldering bonds wires together for extra strength. It’s optional but helpful for tougher jobs.

Pro Tip: Make sure your tools and materials match your wires and connectors. This avoids mistakes and makes assembly easier.

Having the right tools and materials helps you build safe pigtail connections. Being prepared makes the job faster and improves the quality of your work.

Step-by-Step Guide to Making Pigtail Electrical Wire Connections

Making strong pigtail connections needs focus and care. Follow these steps to create safe and reliable connections.

Step 1: Get the Wires Ready

Measure and cut wires to the right size.

First, measure the wires you need. Use a ruler or tape to check the length. Cut the wires with wire cutters to the correct size. Keep them at least six inches long for safety.

Remove the plastic cover from the wire ends.

Use a wire stripper to take off the plastic cover. Expose about half an inch of the copper wire. Be careful not to harm the wire strands. Cleanly stripped wires make better connections.

Step 2: Join the Wires

Twist the bare wire ends together tightly.

Place the bare ends of the wires side by side. Twist them together firmly with your fingers or pliers. A tight twist keeps the wires in place and helps electricity flow.

Put the twisted wires into a connector or sleeve.

Take a pigtail connector or crimp sleeve. Push the twisted wires all the way inside. This step keeps the wires neat and stops them from loosening.

Secure the connection with a crimping tool or by twisting.

If using a crimp sleeve, press it tightly with a crimping tool. For a pigtail connector, twist it firmly to lock the wires. A secure connection lowers the chance of problems.

Step 3: Cover and Protect the Connection

Slide heat shrink tubing over the connection and heat it.

Place heat shrink tubing over the connection. Use a heat gun or lighter to shrink it tightly around the wires. This step protects the connection from dirt and water.

Use electrical tape if heat shrink tubing isn’t available.

If you don’t have heat shrink tubing, wrap the connection with electrical tape. Cover all exposed areas for insulation. Electrical tape works but isn’t as strong as heat shrink tubing.

Pro Tip: Test your connections when done. Use a multimeter to check if the pigtails work properly.

By following these steps, you can make safe and strong pigtail connections. These connections make wiring easier and more reliable in vehicles.

Step 4: Test the Connection

Use a multimeter to check if the connection works.

Testing makes sure your connection is safe and working. A multimeter is the best tool for this job. Follow these steps to test your pigtail connection:

Set the multimeter to continuity mode

Turn the multimeter dial to the continuity setting. This mode checks if electricity flows smoothly. Look for a symbol like sound waves or a diode.Place the probes on the connection points

Touch the multimeter probes to the wire ends or connector terminals. Make sure the probes touch the metal parts firmly for accurate results.Check the multimeter reading

Watch the display or listen for a beep. A beep or a reading near zero means the connection is good. No sound or a high reading means there’s a problem.Inspect the connection for problems

If the test fails, check the connection. Look for loose wires, bad twists, or weak crimping. Fix any issues and test again until the multimeter shows continuity.

Pro Tip: Always test connections before using them in a vehicle. This step avoids electrical problems and keeps things safe.

Testing with a multimeter ensures your pigtail connection is strong. This final step confirms your work is reliable and prevents future wiring issues.

Safety Tips for Pigtail Electrical Wire Connections

Safety is very important when working with electrical wires. Following safety rules keeps your work safe and prevents accidents. Here are some simple tips and warnings to help you.

General Safety Rules

Turn off power before starting any electrical work.

Always switch off the power before touching wires. This stops electrical shocks and keeps you safe. Use a multimeter to check if the power is off. A multimeter helps confirm there’s no electricity in the wires.

Wear gloves to avoid electrical shocks.

Put on insulated gloves made for electrical work. These gloves protect your hands from live wires. They lower the chance of shocks while you work with wires or tools.

Tip: Keep your workspace clean and dry. Water increases the chance of accidents, and messes can cause mistakes.

Important Warnings

Don’t strip too much insulation from wires.

Take off only the needed amount of plastic cover. Removing too much weakens the wire and makes it break easily. Use a wire stripper to uncover just enough copper for a good connection. Properly stripped wires make strong and safe pigtails.

Cover all connections to stop short circuits.

After joining wires, cover bare parts with heat shrink tubing or tape. Insulation stops wires from touching each other or metal, which can cause problems. A well-covered connection keeps your wiring safe and working well.

Reminder: Test your connections after covering them. A multimeter checks if your pigtails are safe and working right.

By following these safety tips, you can make safe and long-lasting pigtail connections. Staying safe protects you and makes your work last longer.

Benefits of Using Pigtail Connectors in Vehicle Applications

Better Safety

Prevents loose or uncovered wires.

A pigtail connector makes wiring safer by stopping loose or uncovered wires. Loose wires can cause sparks, short circuits, or even fires. These problems might harm your vehicle's electrical system. A well-installed pigtail connector keeps wires tightly secured, lowering these dangers.

The Federal Motor Vehicle Safety Standard (FMVSS) No. 305 stresses safe electrical designs in cars. Using pigtails helps meet these safety rules, ensuring high-quality wiring. Also, wire connector caps add extra protection by keeping connections covered and safe from touch.

Tip: Always check that your connections are tight and fully covered. This small step can stop safety problems.

Stronger Connections

Makes wiring last longer.

A pigtail connector creates a strong and lasting bond between wires. Unlike quick fixes like twisting wires without covering them, pigtail connectors stay secure. They handle the shaking and movement that happens in vehicles. This strength keeps your wiring safe over time, even in tough conditions.

The Electrical Safety Standards for Electric Vehicles call for systems that prevent damage to wires. Using wire connectors helps your wiring last longer. Adding heat shrink tubing or tape protects it from water, dirt, and other harmful things.

Pro Tip: Choose good-quality materials for your pigtail connections. This makes them stronger and more reliable.

Easier Repairs

Helps with fixing and replacing parts.

A pigtail connector makes repairs easier by letting you find and fix wiring problems quickly. You can check one part without messing up the whole system. This saves time, especially in cars with lots of wires.

Pigtails also make replacing parts simple. If a wire or connector breaks, you can swap it out without redoing all the wiring. This matches modern car designs that focus on easy repairs.

Reminder: Label your pigtail connections for easier future repairs. Labels help you find wires fast and avoid mistakes.

Using pigtail connectors improves safety, strength, and repairability in vehicle wiring. These benefits boost your car's electrical system and meet today’s safety standards.

Making pigtail wires has four main steps: prepare, connect, insulate, and test. These steps make sure your wiring is safe and works well. Using tools like wire cutters and testers makes the job easier and better. Always follow safety rules, like turning off power and covering wires, to stay safe.

Pigtail connectors are very useful for vehicle wiring. They keep wires secure, last a long time, and are easy to fix. Whether for cars or homes, these connectors are a strong and smart choice for electrical work.

FAQ

What is a pigtail connection, and why is it important?

A pigtail connection joins many wires into one spot. It uses a connector to keep wires stable and covered. This prevents problems like short circuits or overheating. In vehicles, pigtails make strong connections that handle shaking and tough conditions.

Can I use pigtails to extend short wires?

Yes, pigtails are great for making short wires longer. They let you safely add length without weakening the connection. This is helpful in small spaces where wires are too short.

How do pigtails improve safety in electrical systems?

Pigtails make systems safer by stopping screw terminals from overloading. They also keep connections tight to avoid sparks or fires. For grounding, pigtails ensure the ground wires stay secure and safe.

Are pigtails suitable for grounding connections?

Yes, pigtails work well for grounding wires. They connect many ground wires to one safe spot. This setup lowers the chance of electrical problems and keeps the system safe.

What tools do I need to make a pigtail connection?

You need wire cutters, strippers, and a crimping tool. A heat gun or lighter is used for shrinking tubing. A multimeter is also needed to test the connection. These tools help make strong and neat pigtails.

How do pigtails save space in electrical boxes?

Pigtails save space by combining wires into one connector. This keeps the box tidy and easy to work with. It also makes future repairs or changes simpler.

Can I use pigtails in everyday wiring projects?

Yes, pigtails are useful for many wiring jobs. They are good for homes and cars. Pigtails make connections safer and easier to fix, so they are a smart choice.

Why should I test pigtail connections after assembly?

Testing checks if the pigtail works and is safe. A multimeter helps find loose wires or bad insulation. Testing stops future issues and ensures the system works well.

What materials should I use for pigtail connections?

Use strong wires, good connectors, and heat shrink tubing. For grounding, pick the right ground wires for safety. Good materials make the connection last longer and work better.

How do pigtails benefit vehicle wiring systems?

Pigtails make vehicle wiring stronger and more durable. They save space and handle tough conditions. Pigtails also make fixing and replacing parts easier, which is great for cars.

See Also

Why HSD Cable Assemblies Matter in Today's Tech

Improving Data Transfer in Cars with Advanced Connectors

Understanding HSD Connectors for Automotive Applications

Harnessing FAKRA Coaxial Connectors for Enhanced Performance