Are Your Car Connectors Reliable Enough?

Automotive electrical connectors types are crucial for ensuring the smooth operation of vehicles. These connectors play a vital role in maintaining stable connections within car systems. It is essential for automotive manufacturers to use reliable connector types to prevent issues. Research indicates that electric cars experience 79% more problems than gas-powered cars, highlighting the importance of high-quality connectors. The longevity of connectors directly impacts their performance over time. With advancing technology, maintaining low contact resistance is essential to prevent issues and ensure safety in automotive applications.

Challenges and Needs of Car Connectors

Car electrical connectors face many challenges in tough vehicle environments. These connectors need to meet certain needs to work well. Knowing these challenges helps pick the right connectors for cars.

Handling the Environment

Car connectors must handle bad weather conditions. They deal with very hot or cold temperatures, dust, and water, which can hurt how they work.

Dealing with Heat

Heat is a big issue for car electrical connectors. Cars make a lot of heat near engines and exhausts. Connectors need to handle this heat without breaking down. Makers use special materials that don’t melt easily to keep connections stable. This makes sure car systems work even when it’s hot.

Keeping Out Dust and Water

Dust and water are big problems for car electrical connectors. They can get inside and cause rust or stop working. To fix this, makers use seals that block dust and water from getting in. Waterproof connectors help protect against these things too. This keeps them working well in all kinds of weather.

Lasting Long Time

Lasting a long time is important for car electrical connectors. Cars move a lot and shake, which can wear them out over time.

Wear Over Time

Wear happens as connectors are used again and again. The stuff they’re made of needs to last to keep working well for a long time. Makers test how strong they are to see how long they’ll last. This testing finds weak spots so designs can be better.

Handling Shakes and Bumps

Handling shakes and bumps is key for car electrical connectors. Cars shake from roads and engines, which can loosen connections. Connectors need to stay tight during these shakes to keep electric connections steady. Studies show making them stiffer helps reduce shaking effects on connections’ strength.

Science Research Shows:

Electric Contact Strength: More stiffness lowers changes in electric contact strength during shaking.

Reliability Model: A new model helps predict connector reliability early on.

Car electrical connectors must beat these challenges to keep cars safe and running well. By knowing what’s needed, makers can build reliable connectors for tough car conditions.

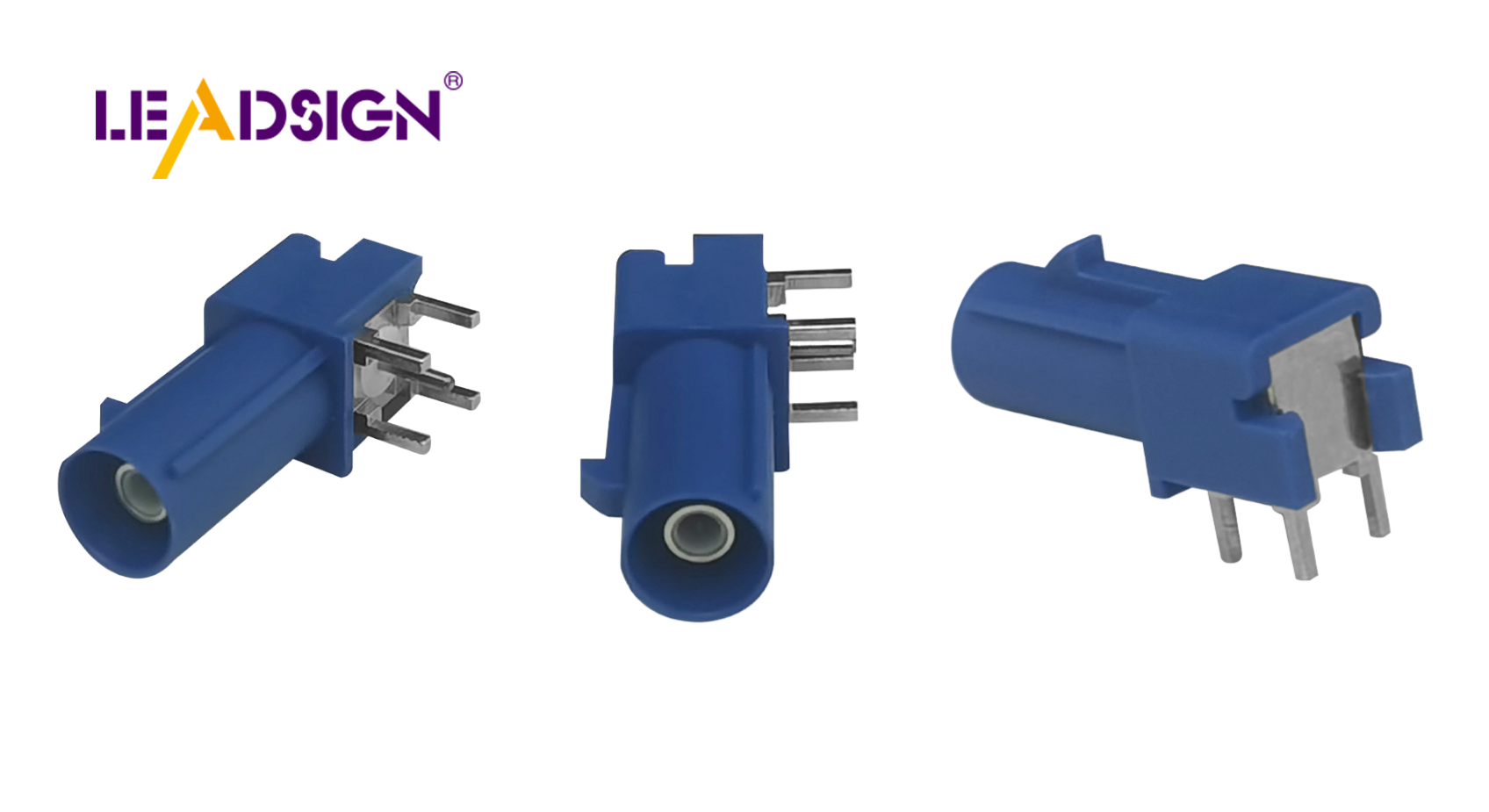

Introduction to FAKRA Connectors

FAKRA connectors are important in cars because they are strong and work well. They are made to handle the tough needs of today's vehicles, helping with smooth communication. FAKRA connectors are important

Benefits of FAKRA Connectors Benefits of FAKRA Connectors

FAKRA connectors have many good points that make them great for cars.

Standardization

FAKRA connectors follow strict rules, so they fit with different systems and makers. This makes it easier to put together parts on the assembly line. Rosenberger’s high-quality FAKRA connectors have color-coded covers that match industry standards. This stops mix-ups and makes sure each connector fits right with its part.

Ease of Installation

FAKRA connectors are easy to install. They have a double-lock system that keeps them secure and stops them from coming loose due to shaking. JPC’s FAKRA cable assemblies show this by being very good against vibrations, making them reliable for car use. Their simple plug-and-play design saves time and effort when installing.

FAKRA Product Portfolio

The FAKRA product range is wide, meeting many car needs.

Range of Products

FAKRA connectors come in different types for various uses. Amphenol’s FAKRA & FAKRA II connectors can work up to 6 GHz, handling the tough demands of cars. They come as cable, PCB, or panel connectors, giving choices for what fits best.

Applications in Automotive Industry

FAKRA connectors are used in many car systems like GPS and radios. Molex Custom FAKRA RF Connectors meet both USCAR and German standards, so they can be used worldwide. Their waterproof design helps them last in harsh car conditions.

Comparing with Other Connectors

DEUTSCH Connectors

Features and Benefits

DEUTSCH connectors are strong and reliable. They are made to last in tough places, perfect for cars. These connectors lock tightly, keeping connections stable even when it's rough. They have seals that protect from dust and water, making them last long.

Strong Design: Made for tough conditions.

Tight Locking: Keeps connections stable.

Seals: Block dust and water.

Use Cases

DEUTSCH connectors are used a lot in car systems. They're found in engines where it’s hot and shaky. They're also in off-road vehicles and big machines where they need to be very reliable.

Engines: Handle heat and shakes.

Off-Road Vehicles: Stay reliable in hard conditions.

Big Machines: Work well in tough spots.

TE Connectivity Solutions

Features and Benefits

TE Connectivity makes connectors for cars that resist shaking and rusting. They use special materials that make them last longer. These connectors are easy to put together and fix. They work well in extreme heat or cold, making them good for car systems.

Shake and Rust Resistance: Lasts long.

Special Materials: Makes them durable.

Easy Design: Simple to install.

Use Cases

TE Connectivity connectors are used widely in cars. They're common in electrical parts where reliability is key. These connectors are also found in safety gear like airbags, needing steady performance.

Electrical Parts: Give steady connections.

Safety Gear: Keep working right.

Many Uses: Fit different car needs.

Why Reliable Connectors Matter in Cars

Safety Concerns

Stopping Electrical Problems

Good connectors stop electrical problems in cars. They keep connections steady, which is important for car systems to work well. If connectors break, important things like brakes and lights can fail. This is dangerous for drivers and passengers. Good connectors stop electrical problems.

Study Findings: Research shows testing connectors before selling them is key. It makes sure they handle the tough car environment and lowers chances of failures.

Keeping Things Working Right

Connectors must work well even when cars shake or get hot. This keeps all car parts working as they should, making driving safer and smoother.

Study Findings: A study found that how stiff a connector is affects its performance during shakes. Knowing this helps make better connectors that stay reliable.

Money Matters

Fixing Costs

Bad connectors can make fixing cars expensive. When they fail, other parts might break too, costing more to fix. Using good connectors means fewer repairs and saves money for everyone.

Study Findings: Looking at why connectors fail helps improve their design. Better designs mean fewer breaks and lower repair costs.

Making Cars Last Longer

Good connectors help cars last longer by keeping everything working right over time. This means less wear on parts, making the car last longer and saving money on new ones.

In short, having good car connectors is important for safety, saving repair money, and making cars last longer. By focusing on these things, makers can build safer and more cost-effective cars that are also better for the planet.

Reliable connectors are very important for car safety and working well. They keep connections steady, which helps cars run smoothly. FAKRA connectors are made just for cars. They work well even in tough weather. Their easy setup makes them popular with makers.

User Experience: "These FAKRA connectors are supposed to be for cars, but with these issues, it's hard to see why they were chosen."

Picking the right connectors is key to making cars safe and last longer. By focusing on reliability, makers can create cars that work great and keep people safe.

See Also

The Significance of FAKRA Connectors in Auto Industry

The Value of HSD Connectors in Auto Sector

Maximizing Auto Data Transfer: Advanced Connectors & Cables

The Relevance of Fakra Auto Connectors in Contemporary Cars

Improving Data Transfer: The Significance of High-Speed Auto Connectors