Applications of Automotive Connectors in Modern Vehicles

Automotive connectors serve as essential components in modern vehicles. These connectors facilitate communication between various electronic systems, ensuring seamless operation. The role of automotive connectors extends to relaying electrical signals across different vehicle systems. This function enhances the dependability and performance of cars. As the "blood vessel" of the automobile assembly system, connectors play a crucial role in connection and transmission. The demand for more durable wiring and connectors has increased due to advancements in vehicle networking and microprocessor control.

Understanding Automotive Connectors

Basic Definitions

What are automotive connectors?

Automotive connectors serve as essential components in vehicles. These connectors facilitate communication between various electronic systems. Different shapes, sizes, and configurations exist to cater to many electrical functionalities. Common types include pigtail connectors, terminal blocks, bullet connectors, and scotch locks. Connector Experts assemble genuine automotive connectors in-house, ensuring quality and reliability.

Key components and materials

Key components of automotive connectors include housings, terminals, and seals. Housings protect the internal components from environmental factors. Terminals provide the conductive path for electrical signals. Seals prevent moisture and dirt from entering the connector. Manufacturers use top materials to ensure sturdiness and resistance to harsh conditions. OEM wiring connections exemplify this with their durability and performance.

Importance in Vehicle Systems

Role in electrical systems

Automotive connectors play a critical role in vehicle electrical systems. These connectors enable electronic components to communicate effectively. The connectors relay electrical signals across various vehicle systems. This function ensures a smooth driving experience. Wire connector types form the bridge between different circuits, allowing seamless integration.

Impact on vehicle performance

The impact of automotive connectors on vehicle performance is significant. These connectors ensure correct and steady electrical connections. Proper connections contribute to the well operation of various automobile parts. The dependability and overall performance of modern cars improve with high-quality connectors. The demand for durable wiring and connectors continues to rise with advancements in vehicle technology.

Types of Automotive Connectors

Classification by Function

Power connectors

Power connectors serve as vital components in modern vehicles. These connectors ensure efficient power distribution across various systems. Power connectors handle high current loads, making them essential for engine and battery connections. Automotive connectors in this category include terminal blocks and pigtail connectors. These connectors provide reliable electrical pathways, enhancing vehicle performance.

Signal connectors

Signal connectors facilitate communication between electronic systems. These connectors transmit data and control signals within the vehicle. Signal connectors play a crucial role in infotainment and navigation systems. Bullet connectors and Scotch Locks are common types used for signal transmission. Automotive connectors in this category ensure accurate data flow, improving system functionality.

Classification by Design

Sealed connectors

Sealed connectors protect against environmental factors. These connectors prevent moisture and dirt from entering the connection points. Sealed connectors use gaskets or seals to maintain integrity. Automotive connectors in this design category enhance reliability in harsh conditions. OEM automotive connectors often feature sealed designs for durability.

Unsealed connectors

Unsealed connectors offer flexibility in less demanding environments. These connectors provide easy access for maintenance and repairs. Unsealed connectors suit applications where environmental protection is not critical. Automotive connectors in this category include wire connectors for internal vehicle systems. These connectors allow quick and efficient connections, facilitating system integration.

Benefits of Using Automotive Connectors

Enhanced Reliability

Improved electrical connectivity

Automotive connectors significantly enhance the reliability of vehicle systems. These connectors ensure optimal electrical connectivity by providing secure and stable connections between various electronic components. The use of high-quality materials in automotive connectors minimizes resistance and voltage drop, which leads to improved performance of electrical systems. This enhancement is crucial for maintaining the functionality of critical systems such as infotainment, navigation, and safety features.

Reduced risk of failure

The design and construction of automotive connectors reduce the risk of system failures. By ensuring robust connections, these connectors prevent issues such as short circuits and disconnections. The reliability of automotive connectors is vital for the seamless operation of modern vehicles, where electronic systems play a pivotal role. The use of Original Equipment Manufacturer (OEM) connectors further enhances reliability, as they are specifically designed to meet the stringent requirements of automotive applications.

Safety and Efficiency

Protection against environmental factors

Automotive connectors offer protection against harsh environmental factors. Sealed connectors, in particular, guard against moisture, dust, and temperature extremes. This protection ensures that electrical connections remain intact and functional under challenging conditions. The durability of automotive connectors contributes to the overall safety of the vehicle, as it prevents potential malfunctions caused by environmental exposure.

Efficient power distribution

Efficient power distribution is a key benefit of using automotive connectors. These connectors facilitate the smooth transfer of electrical energy across different vehicle systems. Power connectors, designed to handle high current loads, ensure that critical components receive the necessary power supply. This efficiency is essential for the optimal performance of systems such as electric power steering and electronic stability programs. The strategic use of automotive connectors in power distribution networks enhances the overall efficiency of modern vehicles.

Installation Techniques

Proper Installation Procedures

Tools and equipment required

Automotive connector installation requires specific tools and equipment to ensure precision and reliability. Essential tools include wire strippers, crimping tools, and multimeters. Wire strippers help remove insulation from wires without damaging them. Crimping tools secure connectors to the wires, ensuring a firm connection. Multimeters test electrical continuity and voltage levels, verifying the integrity of the connections. Additional equipment such as heat guns may be necessary for heat-shrink tubing applications.

Step-by-step installation guide

A systematic approach to installing automotive connectors enhances efficiency and reliability. The first step involves selecting the appropriate connector type based on the application requirements. Next, prepare the wires by stripping the insulation to expose the conductive material. Insert the stripped wire into the connector terminal and use a crimping tool to secure it firmly. Apply heat-shrink tubing if necessary to provide additional insulation and protection. Finally, use a multimeter to test the connection for continuity and proper voltage levels.

Best Practices

Ensuring secure connections

Ensuring secure connections is critical for the dependability of automotive systems. Proper crimping techniques prevent loose connections that can lead to electrical failures. Regular inspection of connectors for signs of wear or damage helps maintain system integrity. Using high-quality connectors from reliable manufacturers like Eigen enhances the overall performance and safety of the vehicle. Secure connections reduce the risk of short circuits and improve the efficiency of electrical systems.

Regular maintenance tips

Regular maintenance of automotive connectors prolongs their lifespan and ensures optimal performance. Routine cleaning of connectors removes dirt and debris that can interfere with electrical conductivity. Inspecting seals and gaskets in sealed connectors prevents moisture ingress and corrosion. Replacing damaged or worn connectors promptly avoids potential system failures. Adhering to these maintenance practices enhances the reliability and safety of modern vehicles.

Common Issues and Solutions

Identifying Common Problems

Corrosion and wear

Corrosion often affects automotive connectors due to exposure to moisture and environmental elements. This corrosion leads to increased resistance in electrical connections. Increased resistance results in poor performance of electronic systems. Wear and tear also contribute to connector failure over time. Regular inspection helps identify signs of corrosion and wear early.

Loose connections

Loose connections pose a significant risk to vehicle systems. These connections cause intermittent electrical failures. Intermittent failures lead to malfunctioning components. Improper installation or vibration from vehicle operation often causes loose connections. Ensuring tight and secure connections prevents these issues.

Troubleshooting and Fixes

Cleaning and maintenance

Proper cleaning and maintenance extend the lifespan of automotive connectors. Use a contact cleaner to remove dirt and corrosion from connectors. A soft brush assists in cleaning hard-to-reach areas. Regular maintenance includes inspecting seals and gaskets for damage. Damaged seals allow moisture ingress, leading to corrosion. Routine checks ensure connectors remain in optimal condition.

Replacement guidelines

Replacement of faulty connectors ensures reliable vehicle performance. Use Original Equipment Manufacturer (OEM) connectors for replacements. OEM connectors guarantee compatibility with vehicle systems. Compatibility reduces the risk of electrical failures. Follow manufacturer guidelines during replacement procedures. Proper installation tools ensure secure and durable connections. Seek professional assistance if unsure about the replacement process.

Future Trends in Automotive Connectors

Technological Advancements

Smart connectors

Smart connectors represent a significant advancement in the realm of automotive connectors. These connectors incorporate intelligent features that enhance functionality. Smart connectors can monitor and report on their own status, providing real-time data to vehicle systems. This capability allows for predictive maintenance, reducing downtime and improving vehicle reliability. The integration of sensors within smart connectors enables precise monitoring of electrical parameters. This innovation supports the growing complexity of modern vehicles.

Integration with IoT

The integration of automotive connectors with the Internet of Things (IoT) marks a transformative trend. IoT-enabled connectors facilitate seamless communication between vehicle systems and external networks. This connectivity enhances the ability to collect and analyze data from various vehicle components. Automotive connectors with IoT capabilities support advanced driver-assistance systems (ADAS). These systems rely on real-time data exchange to improve safety and efficiency. The IoT integration also enables remote diagnostics and software updates, streamlining vehicle maintenance.

Industry Innovations

Eco-friendly materials

The automotive industry increasingly focuses on sustainability. Manufacturers now prioritize eco-friendly materials in the production of automotive connectors. These materials reduce environmental impact while maintaining performance standards. Biodegradable plastics and recyclable metals are examples of sustainable alternatives. The use of eco-friendly materials aligns with global efforts to reduce carbon footprints. This shift reflects a broader commitment to environmental responsibility within the automotive sector.

Miniaturization and design improvements

Miniaturization represents a key trend in the design of automotive connectors. Smaller connectors offer several advantages, including reduced weight and space requirements. This reduction supports the integration of more electronic components within vehicles. Design improvements also enhance the durability and reliability of connectors. Advanced manufacturing techniques enable the production of connectors with superior precision. These innovations contribute to the overall efficiency and performance of modern vehicles.

Automotive connectors play a pivotal role in modern vehicles. These components ensure seamless communication between electronic systems. The dependability and performance of vehicles rely heavily on these connectors. The automotive industry continues to evolve with technological advancements. The demand for durable and reliable connectors increases. Future developments focus on smart connectors and IoT integration. Eco-friendly materials and miniaturization also drive innovation. Understanding these trends is essential for industry professionals. The future of automotive connectors promises exciting possibilities.

See Also

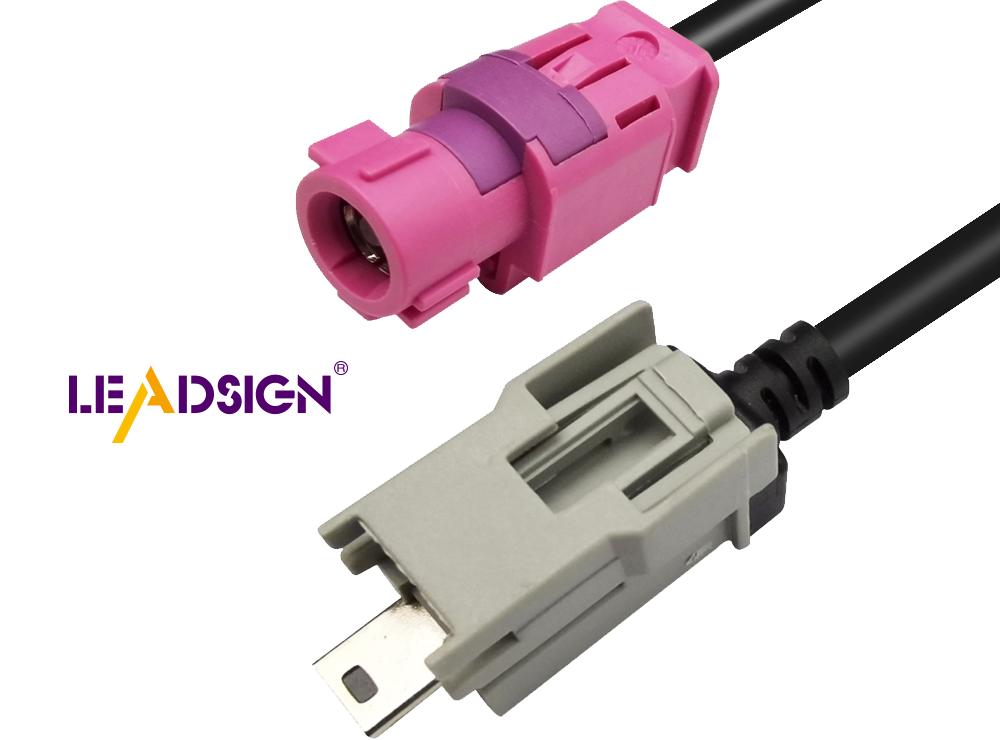

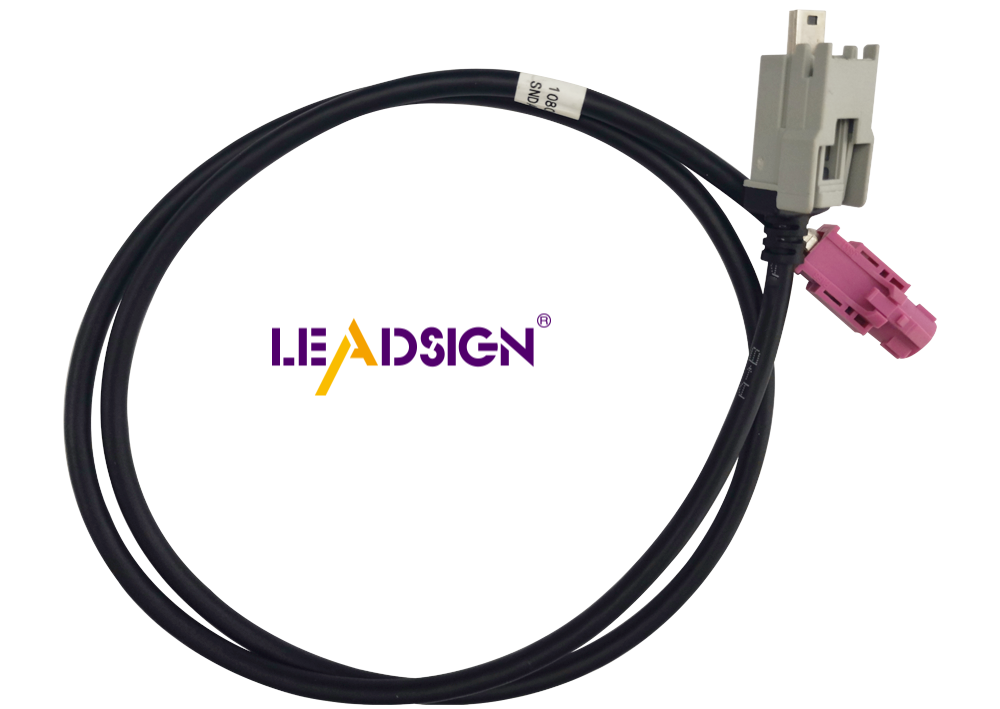

Significance of Fakra Auto Connectors in Contemporary Cars

Benefits of HFM Connectors in Automotive Sector

Fundamentals of HSD Connectors in Auto Sector