Amazing Features of Automotive Electrical Connectors Types

Automotive electrical connectors types are crucial components in modern vehicles. They facilitate the smooth operation of various systems, including audio players and engines. These connectors ensure efficient transmission of electrical signals throughout different car components. Reliable connectors are essential for the longevity and optimal performance of a vehicle's electrical system. They play a vital role in ensuring safety and performance by establishing secure connections. With the increasing technological advancements in cars, the importance of different automotive electrical connectors types becomes even more evident in today's automotive industry.

Types of Automotive Electrical Connectors

Automotive electrical connectors types are key for a car's electric system. They help send power and data between parts. Knowing the different types shows their special uses.

Data Transmission Connectors

These connectors let car systems talk to each other. They make sure data moves smoothly for things like maps, music, and driver help.

High-speed Data Connectors

High-speed ones move lots of data fast. They're important in cars needing quick data swaps. They work with cameras, USBs, and other tech. They focus on speed, strength, and easy setup.

Examples and Applications

USB Connectors: Link phones or tablets to car music systems.

Ethernet Connectors: Move data fast for car networks.

LVDS Connectors: Send video from cameras clearly.

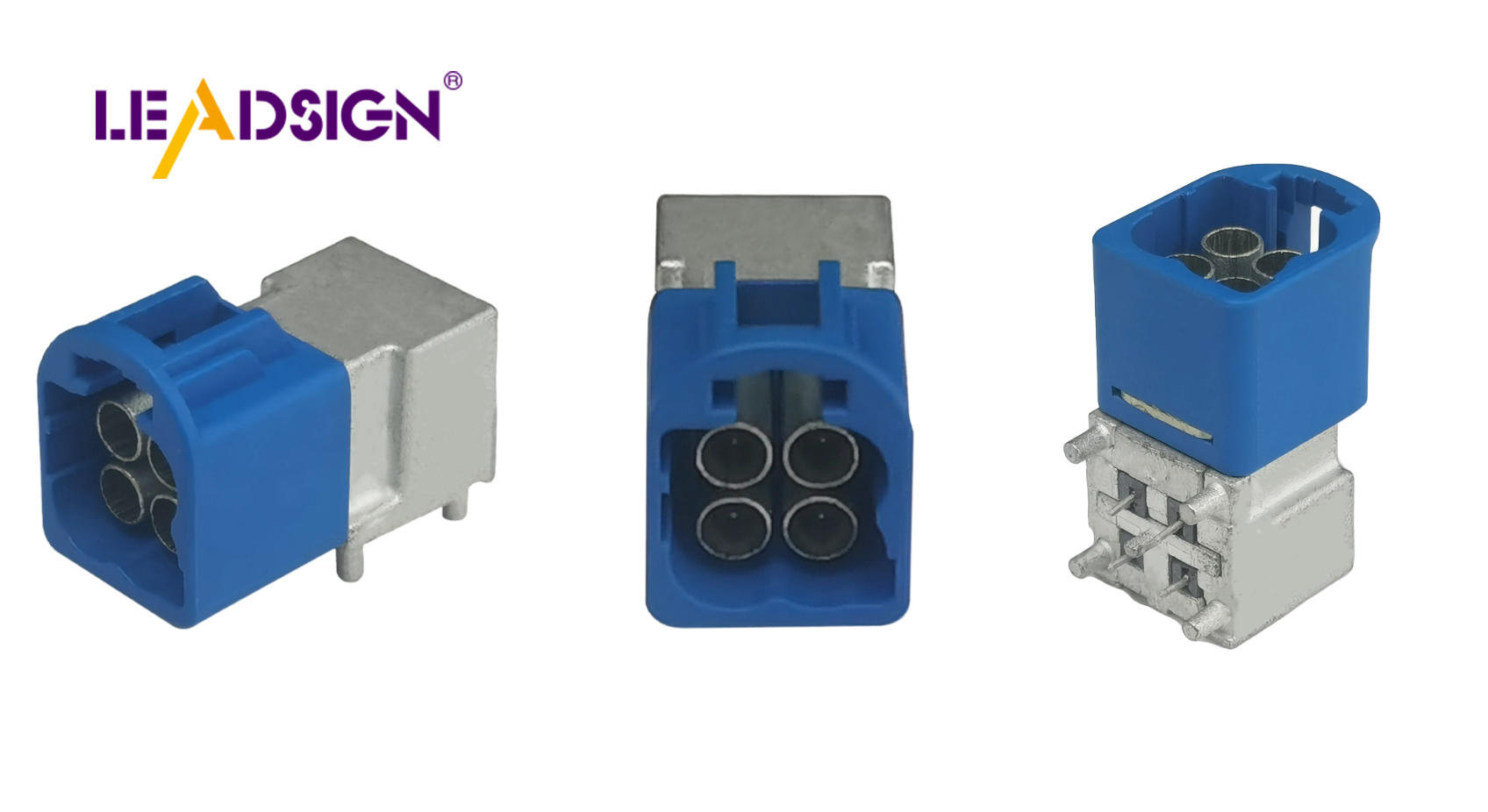

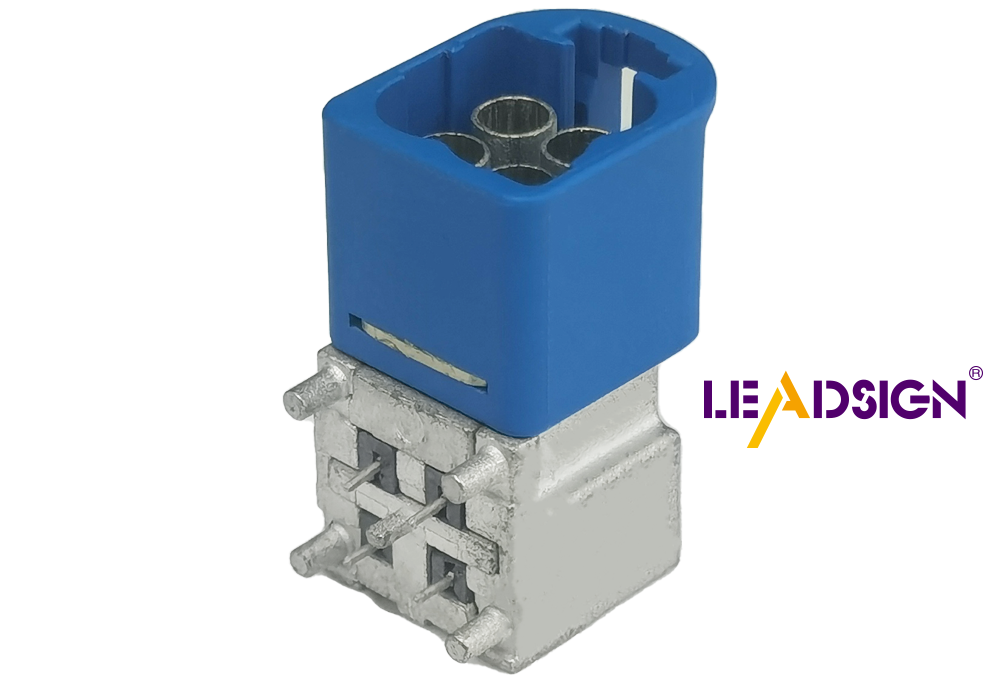

Power Connectors

Power connectors give electricity to car parts. They keep lights, engine start, and battery charging working well.

Features and Importance

They handle high power safely to stop loss. Bigger pins mean better contact for power flow. Made from copper or brass, they resist rust and work well.

Examples and Applications

Battery Connectors: Link battery to the car's electric system.

Lighting Connectors: Power headlights and taillights reliably.

Ignition Connectors: Help start the engine by sending power.

Audio Connectors

Audio connectors send sound signals in cars. They ensure good sound from the audio system.

Specific Features

They keep sound clear without noise problems. Shielding stops interference for steady sound quality.

Examples and Applications

RCA Connectors: Hook up outside audio gear to car speakers.

3.5mm Audio Jacks: Plug in headphones or extra devices easily.

Optical Audio Connectors: Give top-quality sound for fancy systems.

Knowing these connector types shows their value in today's cars. Each type has a job that helps the whole electric system work well.

Mechanical Properties of Connectors

Importance in Automotive and Telecom Industries

Automotive electrical connectors types are important for cars and telecoms. They help electric systems work well. In cars, these connectors send power and data to run different parts. In telecoms, they keep communication networks working.

Durability and reliability

Durability and reliability are key features of automotive electrical connectors types. They must handle tough conditions like heat and shaking. Strong materials like copper and brass make them last long. Regular checks keep them working well and stop problems. This care saves money on fixes later.

Scientific Research Findings:

Mechanical Properties and Reliability of Connectors in Automotive Wire Harnesses show the need for good tools to stop noise issues.

Taking care of wire connectors keeps them working right.

Application Examples

Automotive electrical connectors types are used in many places. In cars, they join engines, lights, and music systems. In telecoms, they connect radio stations and digital lines. These connectors keep things running smoothly.

Automotive Applications:

Connectors link batteries to car electric systems.

They power headlights safely.

They help start engines by sending power.

Telecom Applications:

Connectors keep radio stations connected.

They support digital networks.

Knowing about the mechanical properties of automotive electrical connectors types shows why they're important for smooth car and telecom operations. Their strength makes them a must-have in these fields.

Materials in Connectors

Role in Reliability

Materials are key for connector reliability. They affect how connectors work in different situations.

Common Materials

Connectors often use copper, brass, and plastic. Copper and brass carry electricity well, perfect for power connectors. Plastic is flexible and resists weather.

Pros and Cons

Each material has good points. Copper and brass conduct electricity well, keeping connections stable. But they might rust if not protected. Plastic resists heat and chemicals, making it last longer. Yet, it doesn’t conduct electricity like metals.

Role in Durability

Connector durability relies on materials used. Strong materials help connectors last long even in tough conditions.

New Material Ideas

New ideas improve material quality. For example, special coatings stop metal rusting. These coatings make connectors last longer by blocking water and chemicals.

Real-Life Examples

Studies show how materials affect connector life. One study found coated connectors lasted 30% longer than uncoated ones. Another showed plastic reduced failures in hot places.

Knowing about connector materials helps pick the right ones for jobs. This knowledge keeps connectors strong and reliable, helping car systems work better.

Automotive electrical connectors have amazing features that make cars work better. They help send power and data smoothly, which is very important for today's cars. These connectors keep cars safe by stopping electrical problems and dangers.

Testimonial: "Pigtail connectors are quiet champions in car design, making sure things work well."

In the future, new materials and designs will make connectors last longer and work better. Good connectors like Metri-Pack will stay important in cars. They help with big jobs like fuel injectors and ABS systems.

See Also

Benefits of High-Frequency Modular Connectors in Automotive Sector

Significance of FAKRA Auto Connectors in Contemporary Cars

Benefits of FAKRA Printed Circuit Board Connectors in Auto Uses