Advancements in Auto Wire Connector Types for Modern Vehicles

Automotive electrical connectors types play a crucial role in modern vehicles, ensuring efficient electrical flow. These connectors facilitate the transmission of power and data to various car components. Recent advancements in connector technology have significantly impacted the automotive industry. The global market for automotive connectors is rapidly expanding, with wire-to-wire connectors accounting for 50% of the market in 2022. This trend indicates a growing demand for improved automotive electrical connectors types, which enhance vehicle performance and longevity. As technology evolves, these innovations continue to drive exciting developments in the automotive sector.

Understanding Automotive Electrical Connectors Types

Definition and Functionality

Basic definition of auto wire connectors

Auto wire connectors are key parts in cars. They help send electrical signals and power smoothly. These connectors make sure car systems talk to each other well, keeping the car working right. By joining different circuits, they are vital for the car's functions.

How they function in vehicle systems

In cars, auto wire connectors link wires securely. This allows electricity to flow easily. They ensure power gets to important parts like the engine, lights, and entertainment systems. With a strong connection, these connectors stop electrical problems and improve the car's dependability.

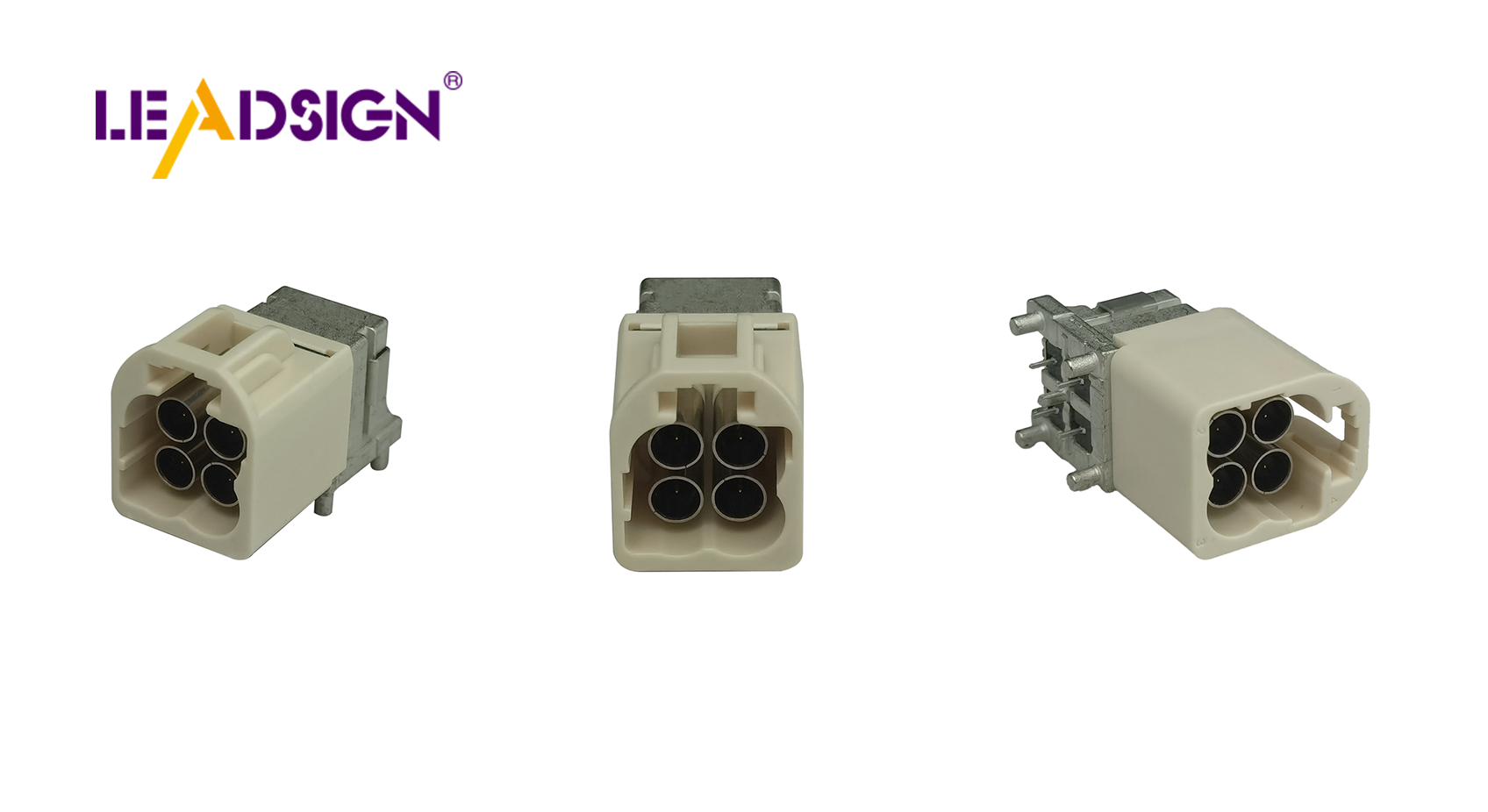

Types of Automotive Electrical Connectors

Traditional connectors

Traditional connectors have been used in cars for many years. They usually have simple designs and materials for basic connections. While dependable, these connectors often miss features needed by new cars. Their limits show in places needing more strength and performance.

Modern connectors

Modern connectors are a big step up in car technology. They use better materials and smart designs for today's cars' needs. These connectors give better insulation, safety, and trustworthiness, fitting them for tough conditions. They can handle high voltages and data speeds, making them key for electric and hybrid cars.

Comparison between traditional and modern connectors

Changing from traditional to modern shows several main differences:

Reliability: Modern ones are more reliable, crucial for complex new energy vehicles.

Insulation and Protection: Better insulation in modern ones ensures safety lasts longer.

Efficiency: Wire-to-wire ones offer direct connections efficiently for advanced systems.

Modern ones work better than traditional ones in function and flexibility, making them important for future car technology.

New Changes in Connector Technology

Better Materials and Designs

Using new materials

Car makers use new materials to make connectors better. These help them last longer and work well. High-voltage car systems get very hot. So, they need materials that manage heat better. This helps connectors handle more power, which is needed for new batteries and quick charging.

Design changes for improved performance

New designs are important for car connector progress. Engineers now make smaller designs to fit tight spaces in cars. Smaller connectors fit easily into modern car setups. Smart designs also make them stronger so they can handle tough conditions in cars. These changes make cars more reliable and efficient.

Improved Safety Features

Safety features in modern connectors

Modern car connectors have smart safety features. They stop electrical problems and keep connections safe. For example, some have locks to stop them from coming loose by accident. This keeps the car running safely with steady electricity flow. Some even have sensors to check things like temperature, making them safer.

Effect on car safety

Better safety features in connectors help keep cars safe. Good connectors lower the chance of electrical issues that can cause big problems. By keeping connections stable, these improvements make cars safer and more reliable. Drivers face fewer electrical troubles, leading to safer trips.

Working with Smart Technologies

Connectors in smart car systems

Car connectors are key in smart vehicle systems now. They help send data smoothly between parts of the car. In smart cars, they support driver aid systems and entertainment setups by sharing data quickly so everything works well together.

Importance in self-driving vehicles

In self-driving cars, good connectors are a must for sensor communication with control units without delay is crucial for safe driving of autonomous vehicles as industry moves towards autonomy advanced connectors become vital supporting these technologies.

Benefits of New Auto Wire Connectors

Better Efficiency

Saving energy in new cars

New car connectors help save energy. They move power smoothly, wasting less energy. This makes cars work better and saves power. It fits with the goal to have better charging and be more eco-friendly.

Less energy loss

New connectors stop energy from being wasted. They keep power from leaking out, so it all goes where it should. This helps the car use less fuel and pollute less.

Stronger Lasting Power

Long life of new connectors

New car connectors last a long time. They are made strong to handle daily use without breaking. Good materials make sure they stay working for years, cutting down on replacements.

Tough against weather

These connectors handle bad weather well. They work in hot or cold places without getting damaged. This keeps the car's electric parts safe and working right.

Saving Money

Cost savings over time

These new connectors save money by lasting longer and needing fewer repairs. This means lower costs for keeping the car running well.

Cheaper upkeep and swaps

With these connectors, you spend less on fixing them or buying new ones often. Cars run smoothly with fewer problems, saving money for owners.

Auto wire connectors have changed cars a lot. They make cars work better, safer, and use less energy. Companies like TE Connectivity and Yazaki are making new designs. Future trends show connectors getting smaller and smarter for self-driving cars. These changes help cars be more reliable and cheaper to fix. As technology gets better, cars will keep improving with these new connectors, leading to more cool ideas and better ways for car parts to connect.

See Also

Maximizing Automotive Data Transmission with Cutting-Edge Connectors

Streamlining Automotive Data Transfer: Innovative Connectors and Wires

Transforming Auto Connectivity: Benefits of High-Frequency Connectors

The Benefits of High-Frequency Connectors in Auto Sector

Boosting Data Transfer: Significance of Fast Automotive Connectors