2024's Most Exciting Trends in Automotive Wire Design

In today's rapidly evolving automotive industry, the design of automotive wire is crucial. As technology advances, staying updated with trends ensures vehicles operate efficiently and safely. Innovative auto wire solutions enhance connectivity and performance. Engineers develop these solutions to meet changing demands, helping to maintain a competitive edge in the market.

New Tech in Car Wire Design

Better Materials for Car Wires

Lighter Wires

Lighter wires change car wire design. Engineers use aluminum and copper mixes to make them lighter. These wires help cars use less fuel. Lighter wires also make cars run better. Car makers like light wires for electric cars.

Heat-Proof Coating

Heat-proof coating keeps car wires safe from heat. Engineers make coatings that handle high temperatures. This stops wire damage near engines. Heat-proof coating makes sure wires last longer in tough places. It helps car wire systems work well for a long time.

Smart Wiring in Cars

Connect with IoT

Connecting with IoT changes car wiring systems. Smart wiring lets cars link to other devices. IoT systems help cars talk better with each other. Sharing data quickly makes cars safer and work better. Engineers create smart wiring for advanced tech in cars.

Cables That Check Themselves

Cables that check themselves are new in car wire design. They find problems and tell users about them early on. Early spotting stops expensive fixes and delays. Self-checking cables make cars more reliable. Makers add this feature to keep customers happy.

Green and Earth-Friendly Car Wire Ideas

Green ideas are important in car wire design today. Engineers make earth-friendly wires to help the planet. Using recyclable stuff for car wires is getting popular.

Recyclable Stuff

Recyclable stuff helps make car wires green. Engineers use things that can be used again or recycled later. This cuts down on trash and saves resources.

Break-Down Insulation

Break-down insulation is a smart idea for car wires. It falls apart naturally over time. Makers use plants to make this kind of insulation. This lowers the bad impact on nature from car wires.

Reusable Clips

Reusable clips boost green ideas in car wire design. These clips let you take apart and put together easily. Engineers make clips strong for many uses without wearing out. This means less new stuff needed, helping a reuse economy.

Energy-Saving Designs

Energy-saving designs matter for today's car wire systems. Engineers try to cut energy waste and do better work. These designs help cars run more efficiently.

Less Power Waste

Less power waste is key in energy-saving wire design. Engineers use cool materials and tricks to lower resistance. This makes sure more power goes where it should go. Less power waste means cars work better and use less energy.

Better Circuit Plans

Better circuit plans are important in saving energy with car wires. Engineers plan how wires and parts fit together carefully. This stops wasting energy and boosts system efficiency. Good plans make auto wire systems last longer and work well.

Car Wire Safety and Strength

Safety and strength are key in car wire design. Engineers make systems for steady work and safety. These changes help cars stay safe in different situations.

Better Protection Methods

Protection methods boost car wire system work. Engineers find ways to guard wires from outside problems. This keeps communication clear inside cars.

Cutting Down on EMI

EMI can harm car wire systems. Engineers make shields to cut down EMI. They use stuff that blocks bad signals. Good shielding makes car wires more reliable. Cars run smoothly and safely.

Stronger Wires

Strong wires are needed for car wire systems. Engineers pick materials that handle tough conditions like heat and shaking. Stronger wires last long and keep working well.

Backup Plans and Safety Steps

Backup plans make car wires more reliable. Engineers add these to stop failures. Cars keep going even if one part breaks.

Two Sets of Wires

Two sets of wires give extra safety. Engineers design them with two wire groups. If one fails, the other works instead. This lowers the chance of big failures, keeping cars safe.

Auto Problem Spotting

Auto problem spotting finds issues in car wires early on. Sensors watch how wires are doing their job. They find faults and warn users quickly. Early fixes stop big troubles and save money, making car wires better.

Future Effects and Industry Changes in Car Wires

Impact on Self-Driving Cars

Better sensor links are key for self-driving cars. Engineers make car wires to work with many sensors. These sensors collect info from around the car. This info helps cars decide what to do. Good car wires send data smoothly, making cars safer.

Strong networks are needed for self-driving cars. Car wires must carry lots of data. Engineers create better wires for these networks. Strong networks help cars talk to roads and signs. This helps with driving and traffic control. Good networks help self-driving tech succeed.

Market Trends and Predictions

More electric car wiring is a big trend now. Electric cars need special wires for batteries and power use. Engineers work on making better wires for electric cars. More people want electric cars, pushing wire tech forward.

More custom solutions change the wire industry too. Makers want special wires for different car needs. Custom wires fit unique vehicle demands well. Engineers design these to boost performance and happiness.

The blog talked about cool car wire trends for 2024. Engineers use new materials and smart wires. They also focus on earth-friendly ideas. Safety and reliability are very important. New wire designs help cars stay safe and work well. Knowing about future wire changes is key. The car industry is changing fast. Learning these trends helps stay ahead. Car wires have a bright future with more improvements coming.

See Also

Maximizing Automotive Data Transfer: Cutting-Edge Connectors and Cables

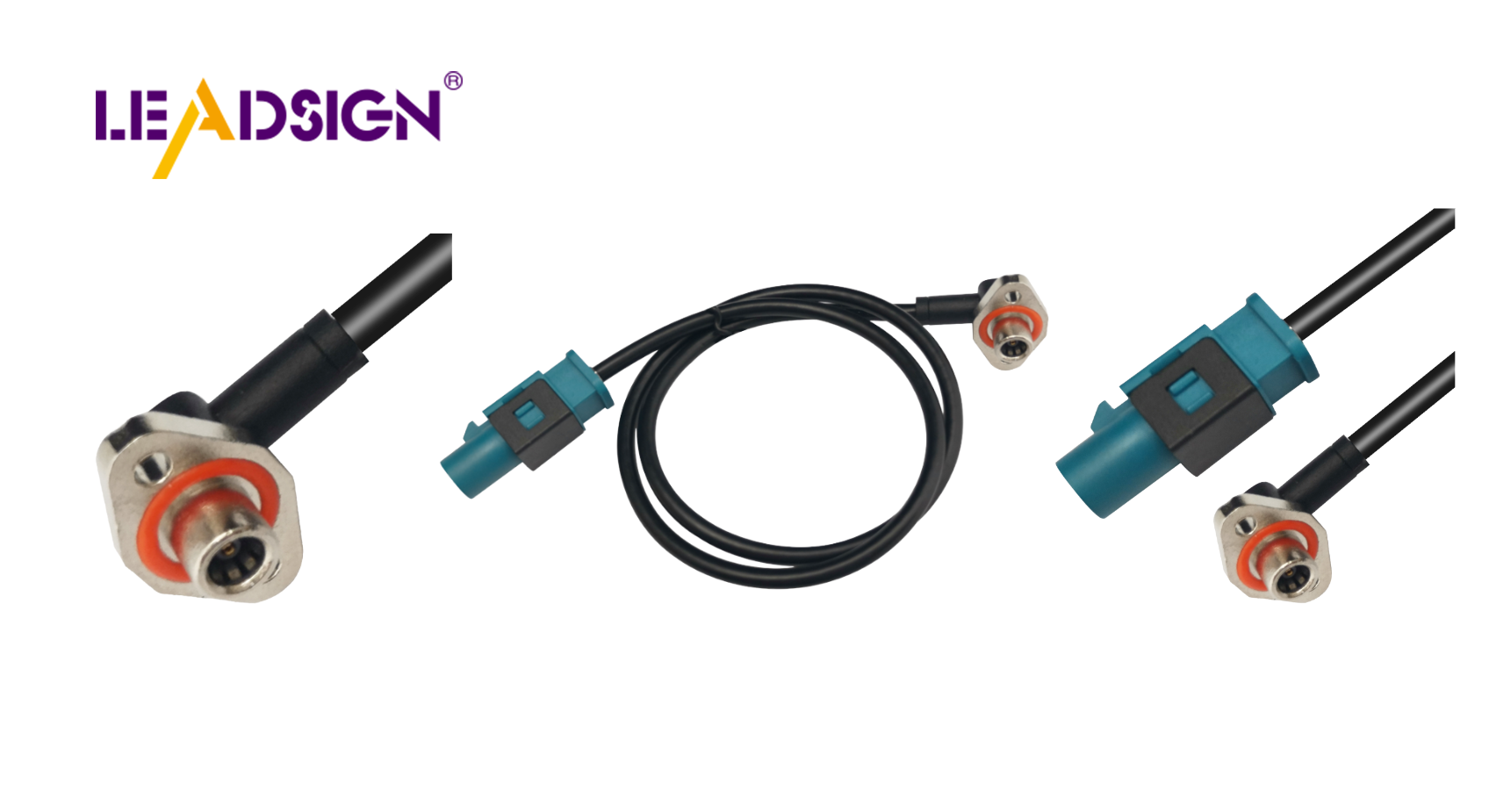

Discovering Opportunities: Rapid FAKRA-Mini Connectors in Automotive

Improving Data Transfer: Significance of High-Speed Auto Connectors